Pencil lead feeding and positioning device of full-automatic pencil pencil-lead filling machine and technology of pencil lead feeding and positioning device

A fully automatic pencil and positioning device technology, which is applied in the directions of packaging, transportation and packaging, and the type of packaged items, and can solve problems affecting production efficiency and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

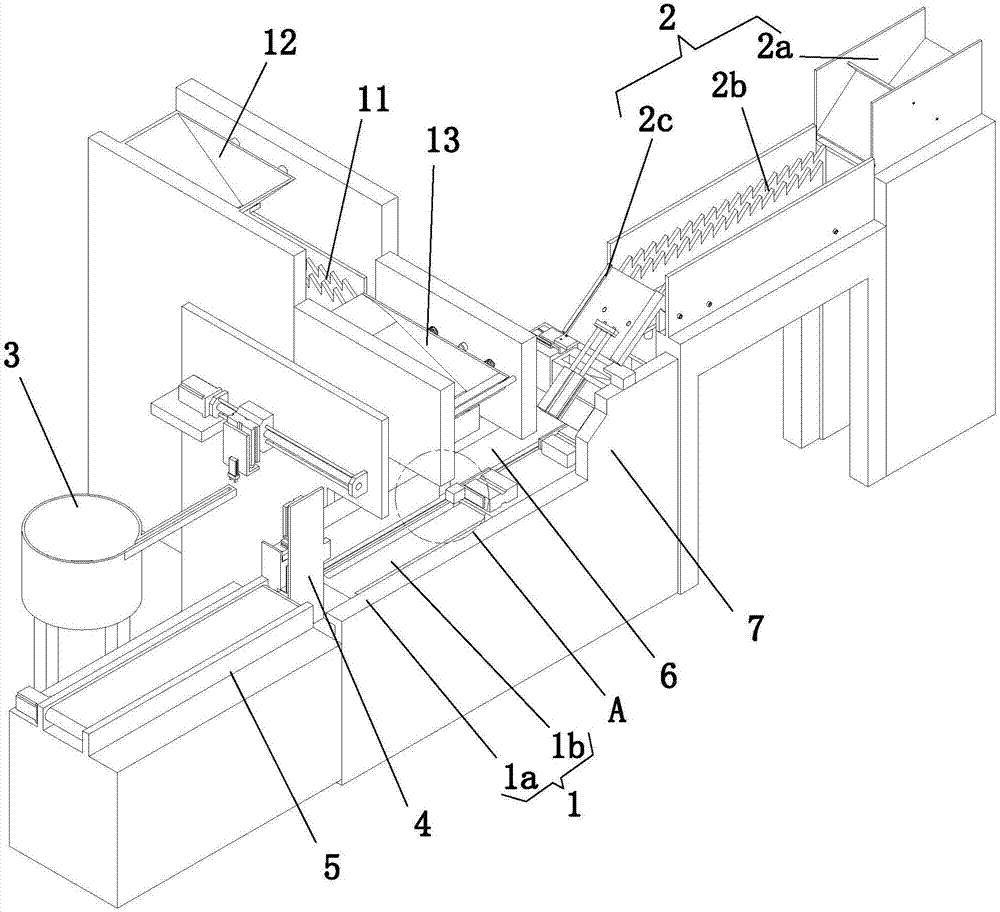

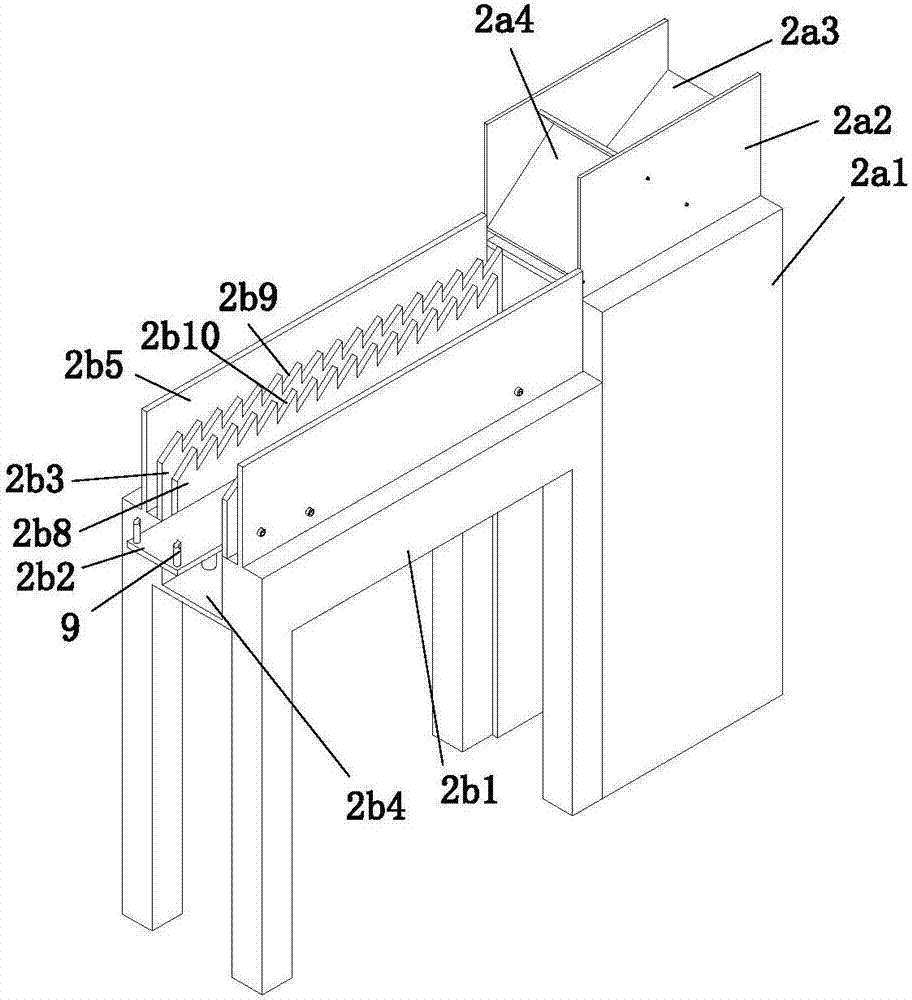

[0034] refer to Figure 1 to Figure 12 The full-automatic pencil lead filling machine shown includes the lead barrel feeding and positioning device 2, the conveying device 1, the lead feeding and positioning device, the lead barrel cover feeding device 3, the pressing device 4 and the finished product conveyor belt 5. The lead core barrel feeding positioning device 2, the conveying device 1 and the finished product conveyor belt 5 are arranged in sequence along the conveying direction of the conveying device 1. The lead core feeding positioning device is vertically arranged with the conveying device 1, and the lead core barrel is covered. The feeding device 3 is located on the side of the lead core feeding and positioning device. The conveying device 1 includes a first frame 1a and a conveying mechanism 1b. The top of the first frame 1a is provided with a mounting groove 1a1, and the conveying mechanism 1b is fixed in the mounting groove 1a1. The pressing device 4 is fixed in ...

Embodiment 2

[0052] The feeding and positioning process of the lead feeding and positioning device of the above-mentioned automatic pencil lead filling machine includes the following steps:

[0053] S1. The lead core barrel conveying mechanism 2b transports the lead core barrel to the designated position, the worker puts the lead core into the second blanking mechanism 12, and the lead core falls from the second blanking mechanism 12 onto the lead core conveying mechanism 11 in sequence;

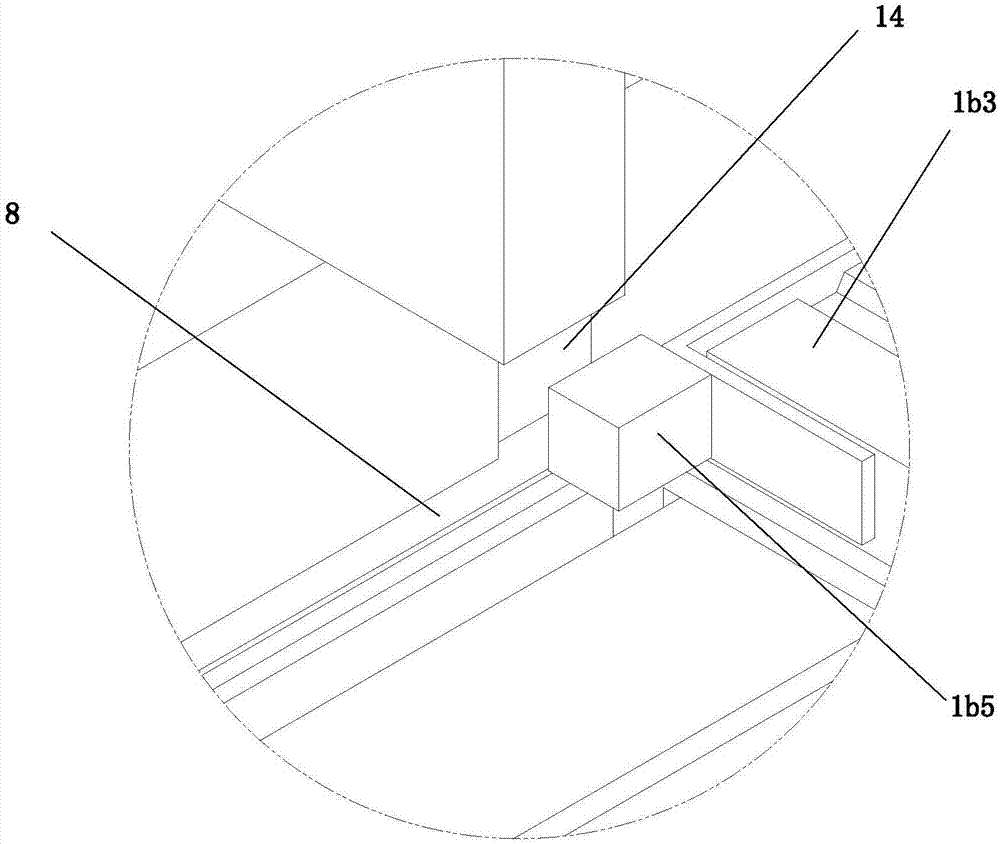

[0054] S2. The lead core conveying mechanism 11 sequentially transports the lead cores to the third blanking mechanism 13. When the fifth cylinder 1b3 of the conveying assembly drives the second abutting block 1b5 to press the sensing mechanism 14, the lead cores are discharged from the third blanking mechanism. Fall in the lead core cylinder in the mechanism 13.

[0055] Specifically, the feeding positioning process of the lead feeding positioning device of the automatic pencil lead filling machine is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com