A preparation method of visible light responsive wooden shutters

A blinds and visible light technology, applied in the field of visible light responsive wood preparation, can solve the problems of wooden blinds damage, waste of sunlight resources, wooden blinds do not have the function of responding to discoloration, etc., achieve high utilization efficiency, increase life interest, and facilitate industrialized assembly lines The effect of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

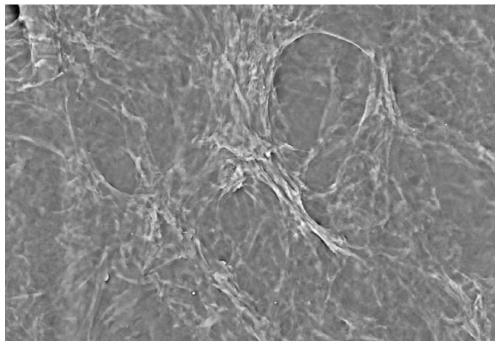

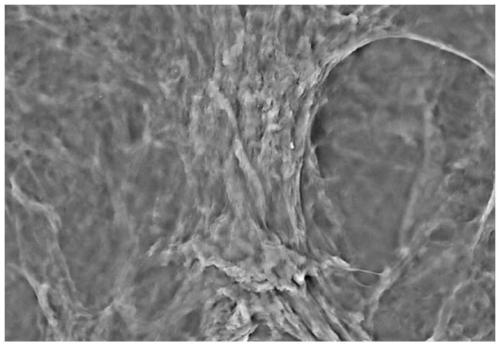

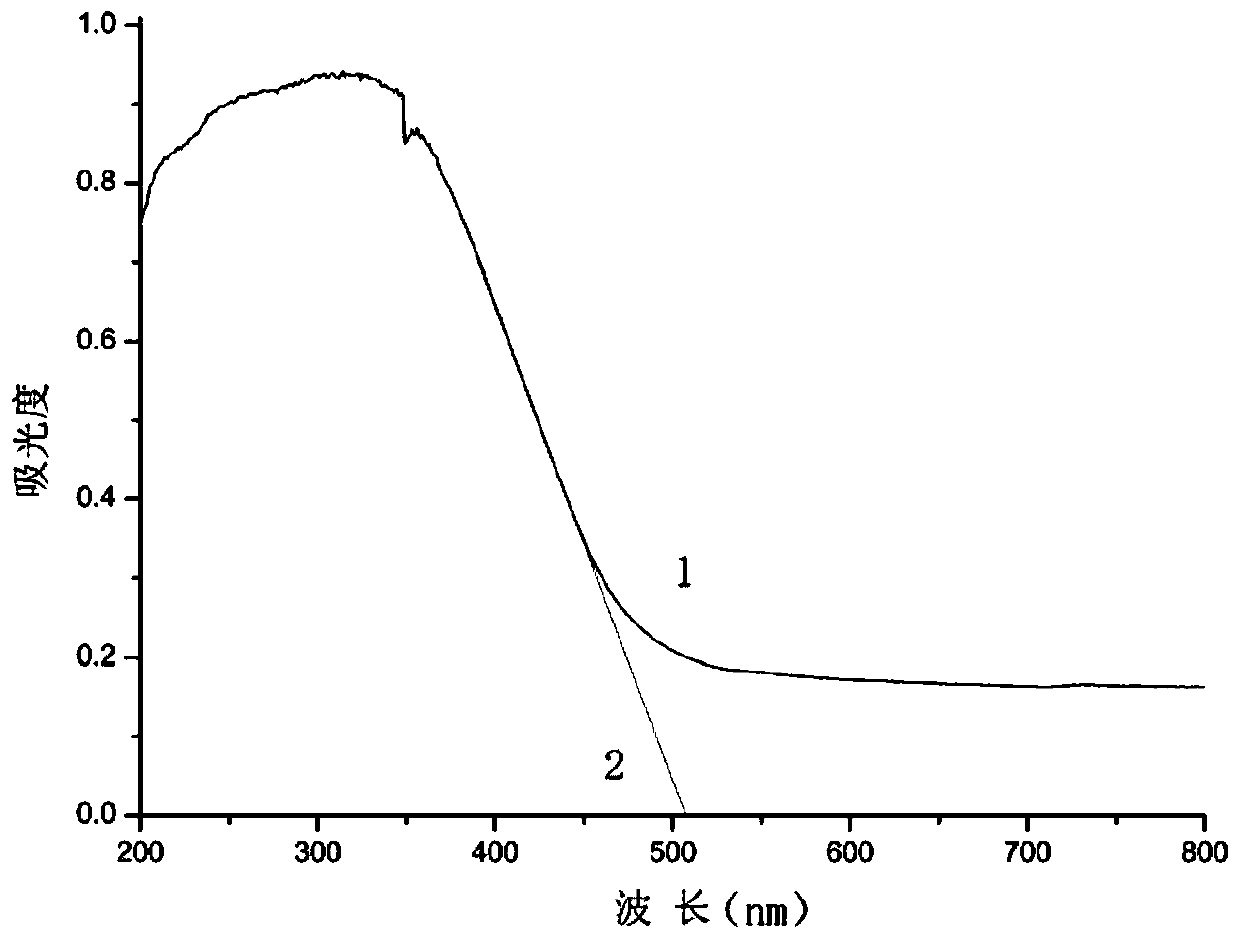

Image

Examples

specific Embodiment approach 1

[0030] Specific embodiment 1: This embodiment is a method for preparing visible light responsive wooden blinds, which is completed in the following steps:

[0031] 1. Prepare solution A:

[0032] Dissolve phosphomolybdic acid in distilled water at room temperature to obtain solution A;

[0033] The volume ratio of the mass of phosphomolybdic acid to the volume of distilled water in step one is (0.3g~0.8g): 100mL;

[0034] 2. Prepare the substrate solution:

[0035] Add polyethylene glycol and sodium alginate to distilled water, and then stir for 3h to 5h at a temperature of 25°C to 35°C and a stirring speed of 700r / min to 900r / min to obtain a base solution;

[0036] The mass ratio of polyethylene glycol to the volume of distilled water in step two is (1g~1.5g): 100mL;

[0037] The ratio of the mass of sodium alginate to the volume of distilled water in step two is (0.3g~0.5g): 100mL;

[0038] 3. Prepare the coating solution:

[0039] Add solution A dropwise to the base solution at a droppin...

specific Embodiment approach 2

[0050] Specific embodiment two: this embodiment is different from specific embodiment one in that the thickness of the coating on the surface of the visible light responsive wood blind described in step four is 10 μm to 15 μm. The other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0051] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the mass ratio of phosphomolybdic acid to the volume of distilled water described in step 1 is (0.3 g˜0.5 g): 100 mL. The other steps are the same as the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com