Speed reducing and energy recycling equipment

A technology of energy recovery and equipment, which is applied in the direction of roads, road signs, traffic signals, etc., can solve the problems of poor recovery effect, no safety prevention and control devices, no speed bumps, etc., and achieve high energy recovery and utilization efficiency. Conducive to the effect of smooth passage and convenient flow control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

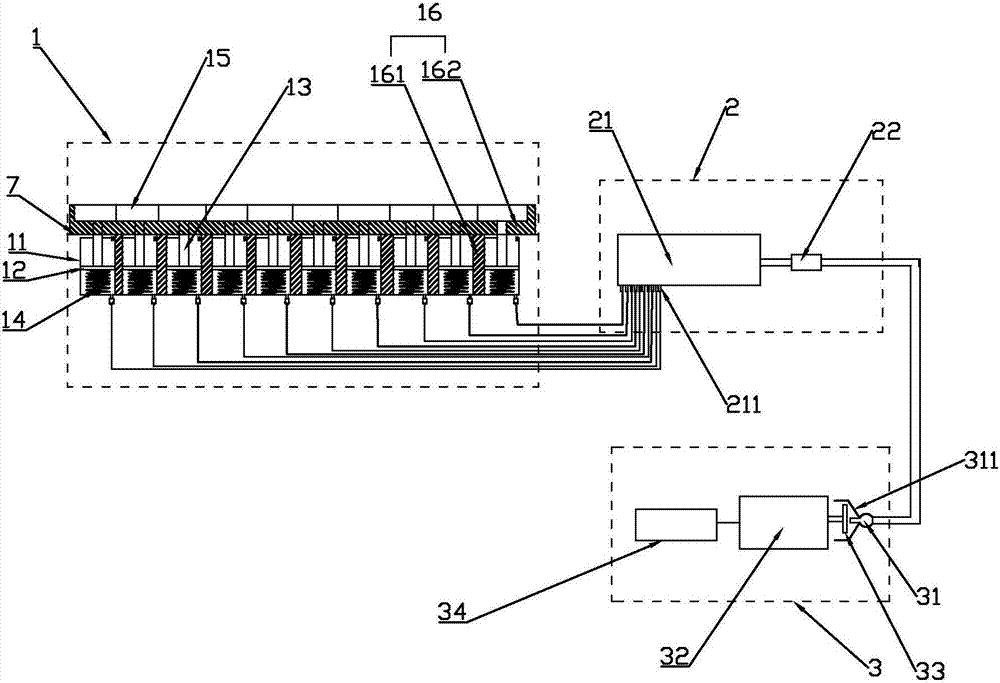

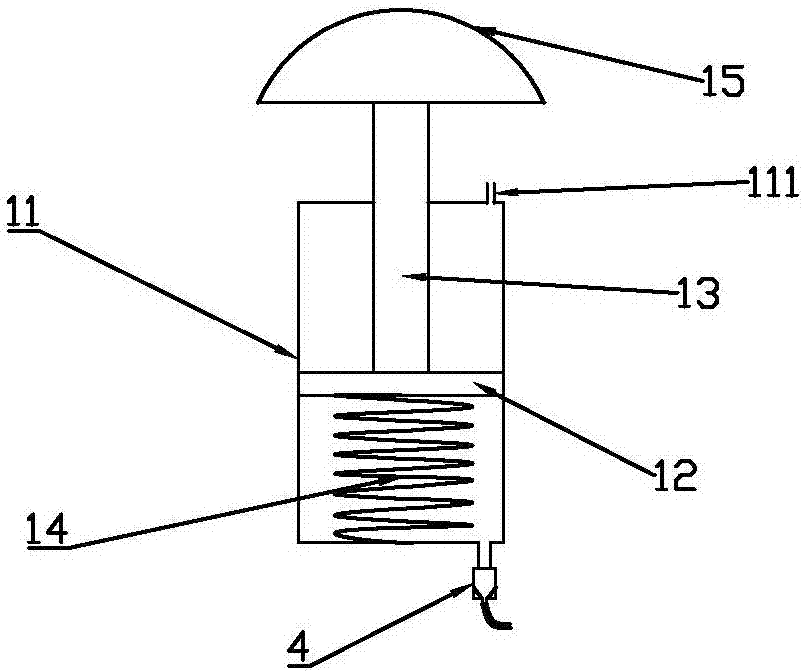

[0029] Such as figure 1 with figure 2 As shown, a deceleration and energy recovery equipment, including an inflator 1 and a gas storage device 2,

[0030] The inflatable device 1 includes a cylinder 11, a piston 12, a piston rod 13, a return spring 14, a contact head 15 and a rubber belt 16. A piston rod guide hole is arranged in the middle of the upper end of the cylinder 11, and an air hole 111 is arranged on one side of the upper end of the cylinder 11. , the lower end of the cylinder 11 is conductively connected to the one-way valve 4, a plurality of the cylinders 11 are arranged side by side in the foundation pit under the road surface, the piston 12 is slidably connected in the cylinder 11, and the lower end of the piston rod 13 is connected to the The upper end of the piston 12 is fixedly connected, the upper end of the piston rod 13 passes through the piston guide hole and is fixedly connected to the middle part of the lower end of the contact head 15, and the lower ...

Embodiment 2

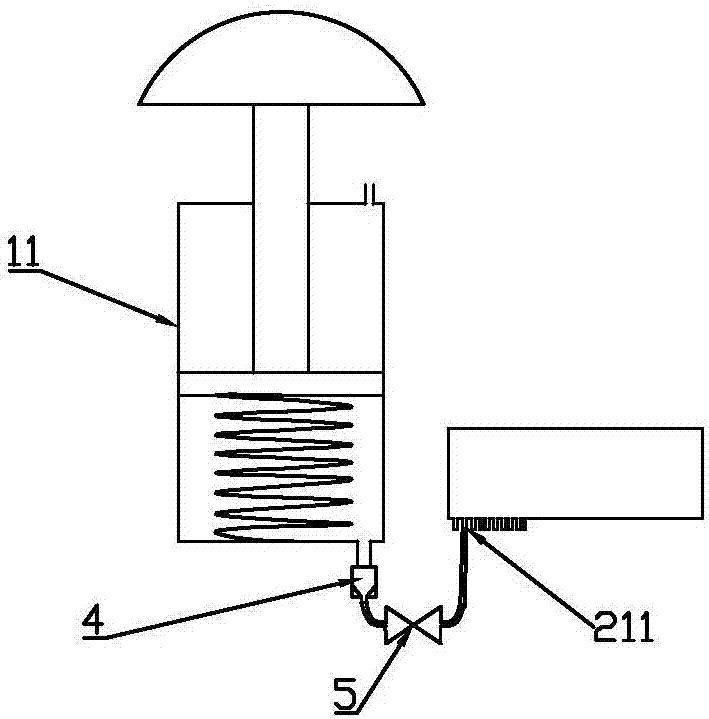

[0042] Such as image 3 As shown, the difference between this embodiment and Embodiment 1 lies in that a control valve 5 is also provided between the one-way valve 4 and the air collecting hole 211 .

[0043] Further, in the above technical solution, the control valve 5 is an electric valve or a solenoid valve.

[0044] The control valve 5 is used to adjust or close the gas outflow in the conduit or block the gas compressed by the cylinder 11 for convenient control.

Embodiment 3

[0046] Such as Figure 4 As shown, the difference between this embodiment and Embodiment 1 is that the height of the deceleration belt 162 and the contact head 15 decreases continuously from the entry end to the exit end.

[0047] Further, in the above technical solution, the contact head 15 is closely matched with the speed reduction belts 162 on both sides.

[0048]By adopting this structure, the vibration received when the motor vehicle passes is greatly reduced.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap