Heat storage device and system

A technology of heat storage device and heat storage system, which is applied in the field of solar heat storage, and can solve problems such as unstable operation of the system, reduced efficiency, and aggravated local turbulent flow at the inlet and outlet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

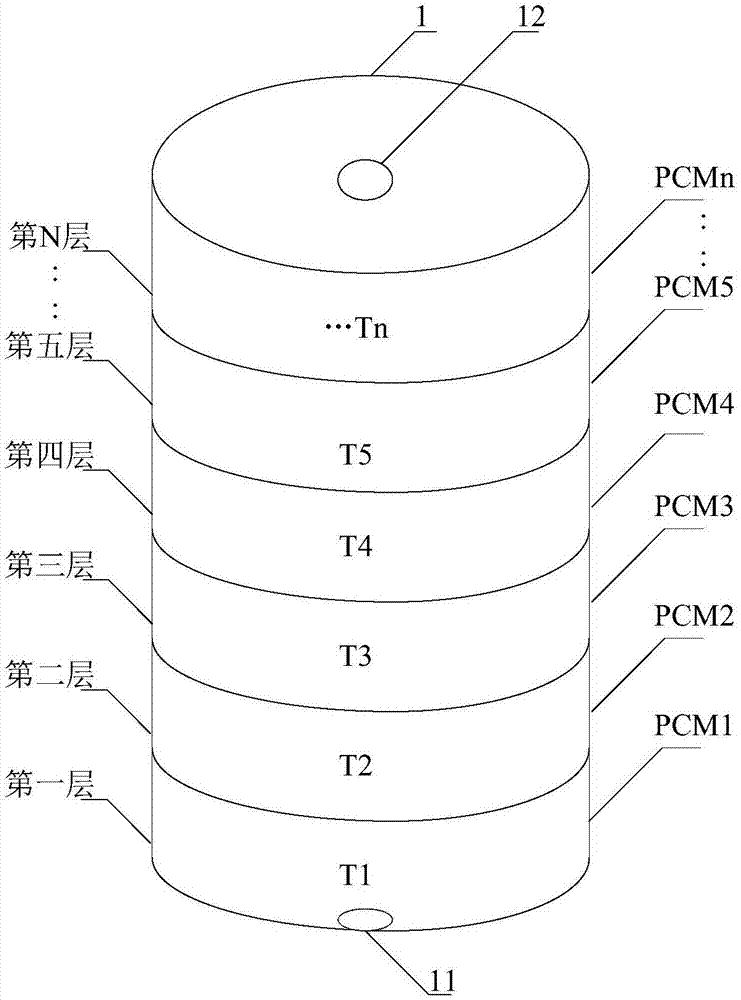

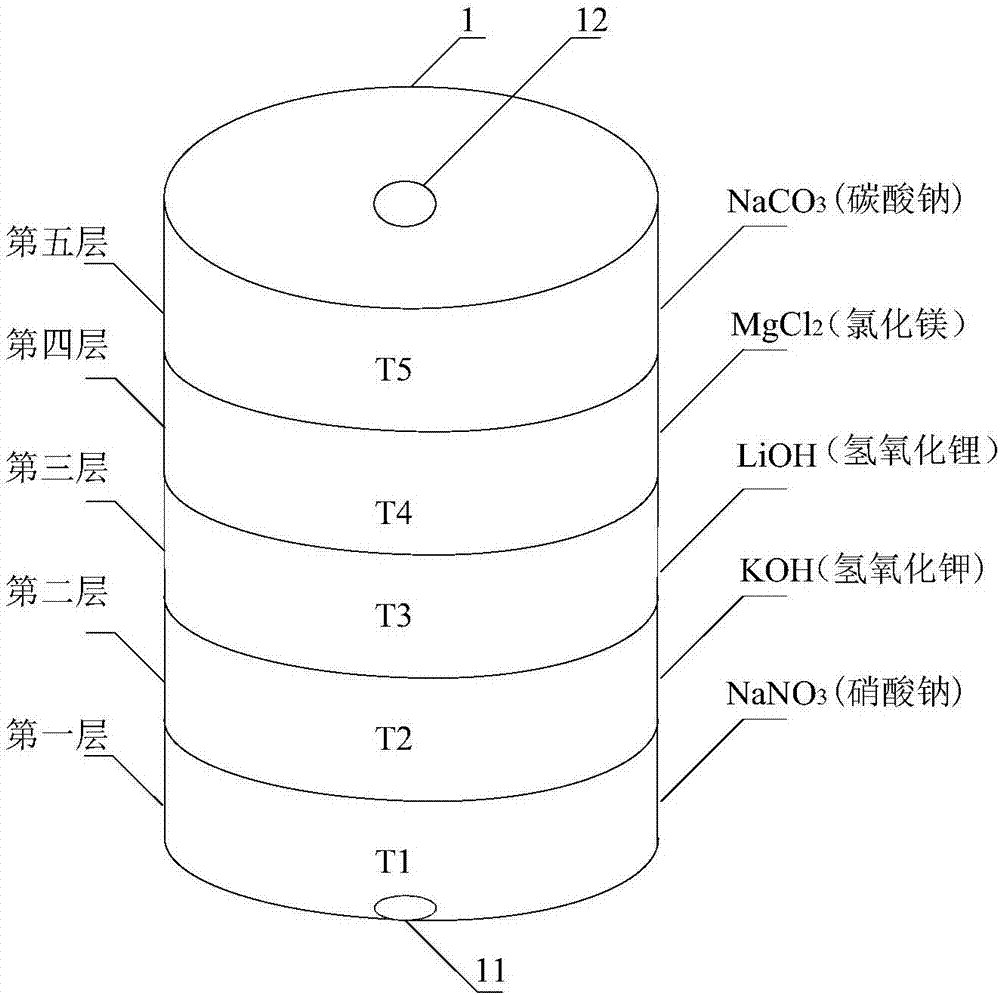

[0040] An embodiment of the present invention provides a heat storage device used in a heat storage system, such as figure 1 As shown, it includes a heat storage tank 1 for heat storage, and the heat storage tank 1 is a cylindrical heat storage tank. The tank diameter and height of the heat storage tank 1 mainly depend on the heat storage temperature and storage temperature. Heat capacity, the heat storage tank body 1 is a cylinder. Both sides of the heat storage tank body 1 are respectively provided with a heat input port 11 and a heat output port 12, and a multi-layer phase change material is arranged in the heat storage tank body 1, which are respectively PCM1, PCM2, PCM3, PCM4, PCM5, ... PCMn , between the heat input port 11 and the heat output port 12, a channel for heat transfer medium circulation is formed through the gap of the multi-layer phase change material, and the phase change temperature of each layer of phase change material increases gradually along the direct...

Embodiment 2

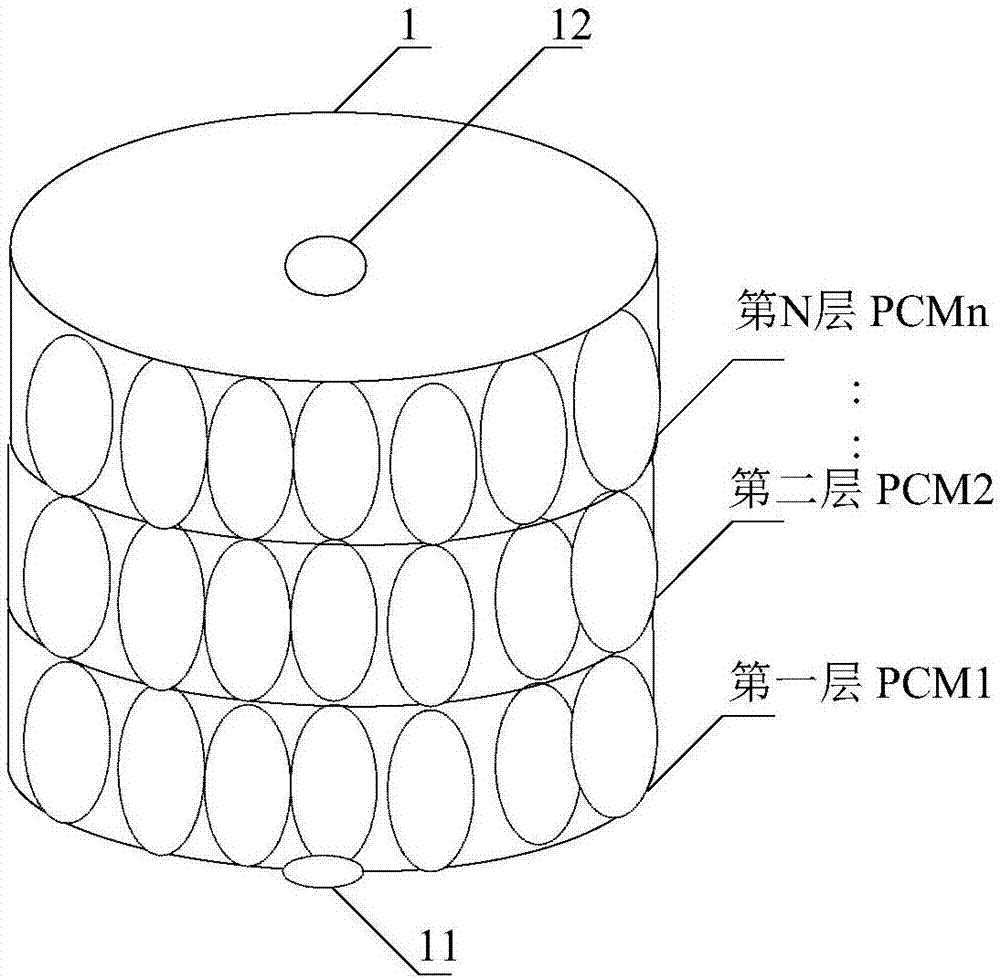

[0055] An embodiment of the present invention provides a heat storage device, such as Figures 3A-3EShown are heat storage devices composed of phase change materials with five structures. It includes a heat storage tank 1 for heat storage. The heat storage tank 1 is a cylindrical heat storage tank. The diameter and height of the heat storage tank 1 mainly depend on the heat storage temperature and heat storage capacity. The hot tank body is a cylinder. Both sides of the heat storage tank body 1 are respectively provided with a heat input port 11 and a heat output port 12, and a multi-layer phase change material is arranged in the heat storage tank body 1, and the heat input port 11 and the heat output port 12 are connected by a multilayer phase change The gaps of the change material form channels for the circulation of the heat transfer medium. The phase change temperature of each layer of phase change material increases gradually along the direction from the heat input port ...

Embodiment 3

[0069] An embodiment of the present invention provides a heat storage device, including a heat storage tank 1 for heat storage, the heat storage tank 1 is a cylindrical heat storage tank, the diameter and height of the heat storage tank 1 are set It mainly depends on the heat storage temperature and heat storage capacity, and the heat storage tank is a cylinder. A heat input port 11 and a heat output port 12 are respectively arranged on both sides of the heat storage tank body 1. In the heat storage tank body 1, a multi-layer phase change material is arranged in a spirally wound coil tube, and the heat storage tank body in this embodiment The heat tank body 1 can form a channel for the heat transfer medium to circulate between the heat input port 11 and the heat output port 12 by arranging a spirally wound coil tube. The phase change temperature of each layer of phase change material is along the heat input port 11 to the heat output port. 12 directions increase one by one, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com