Titanium heat-exchange tube

A technology of titanium tube and titanium layer, which is applied in the field of heat exchange elements, can solve problems such as inability to work for a long time, increase maintenance costs, and limit the use of the environment, and achieve the effects of reducing weight, reducing weight, and improving heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

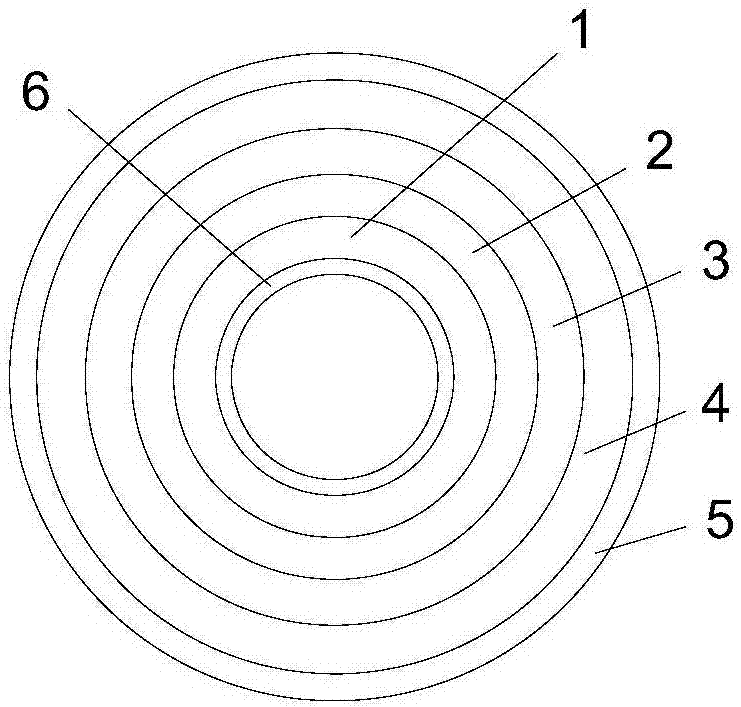

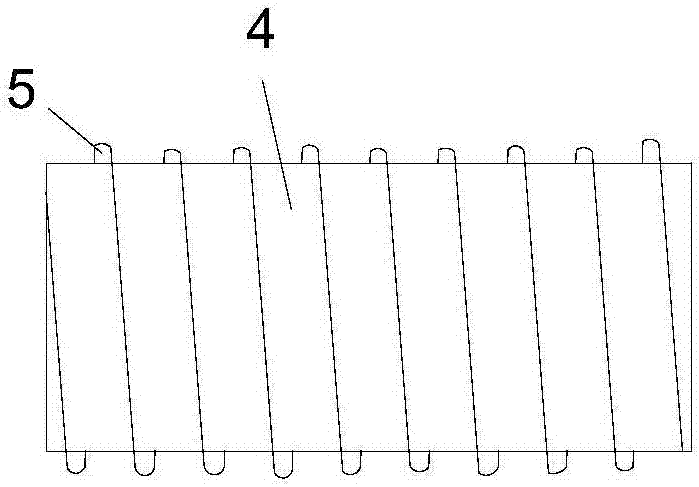

[0014] Such as figure 1 and figure 2 The heat exchange titanium tube of the present invention shown has an inner titanium layer 1, and a flow guide structure 6 of a titanium structure is provided on the inner wall of the inner titanium layer 1, and the flow guide structure 6 is a spiral guide groove. While guiding, the heat exchange area is also increased, which is beneficial to improve the heat exchange efficiency. A ceramic layer 2 is arranged outside the inner titanium layer 1, and the anticorrosion and wear resistance of the heat exchange tube are further improved through the ceramic layer 2. The ceramic layer 2 is provided with an aluminum layer 3 and an outer titanium layer 4 in sequence. The aluminum layer 3 can improve the overall strength of the heat exchange tube, and the outer titanium layer 4 not only has corrosion resistance, but also has the function of wear resistance. The outer wall of the outer titanium layer 4 is provided with a strip-shaped reinforcement ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com