Open system chemical kinetics high-temperature and high-pressure experimental device

A chemical kinetics, high temperature and high pressure technology, applied in the direction of measuring devices, sampling devices, scientific instruments, etc., can solve the problem of hindering the study of chemical kinetics mechanism of the mineralization process, lack of automatic overall control of simulation experimental devices, and difficulty in ensuring temperature and pressure stability And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and examples, but the present invention is not limited in any way. Any changes or improvements made based on the teaching of the present invention belong to the protection scope of the present invention.

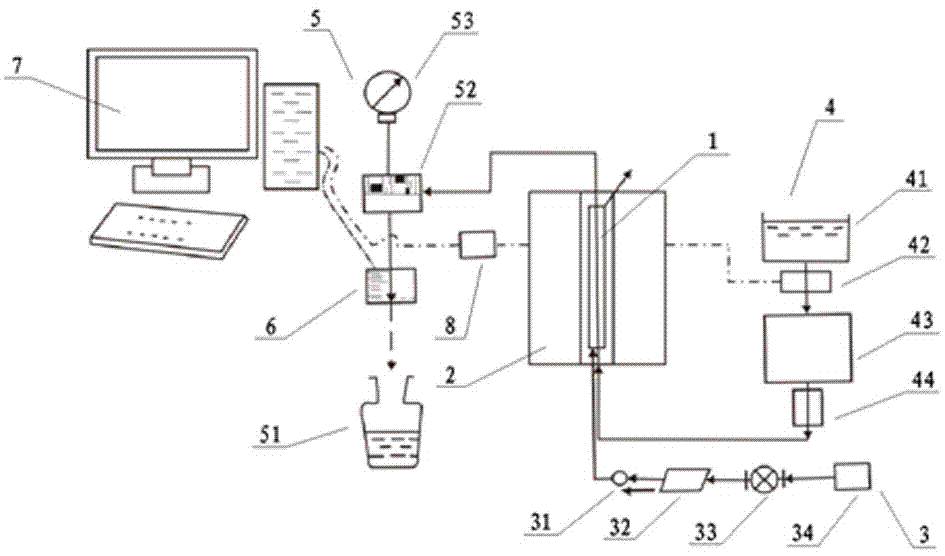

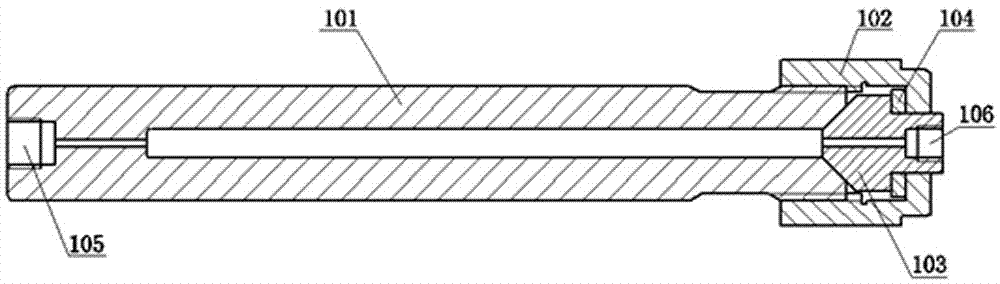

[0019] Such as figure 1 with 2 As shown, the present invention includes a cold-sealed tubular autoclave 1, a temperature-controlled furnace 2, a booster system 3, an online feeding device 4, an online sampling device 5, a multi-parameter detector 6, and a computer 7. Tubular autoclave 1 includes a tubular kettle body with a closed lower end, and a kettle cover that is connected to the upper end of the kettle body by threads to form a closed pressure chamber. The cold-sealed tubular autoclave 1 is buried in a temperature-controlled furnace 2. The output port of the pressure system 3 communicates with the pressure chamber of the cold-sealed tubular autoclave 1, the onlin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com