Load simulation device for metering equipment

A technology of metering equipment and simulation devices, applied in the direction of measuring devices, measuring electricity, measuring electrical variables, etc., can solve problems such as no phase voltage and phase current, instability, short circuit between phases or phase to ground, etc., to improve work efficiency, The effect of protecting safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

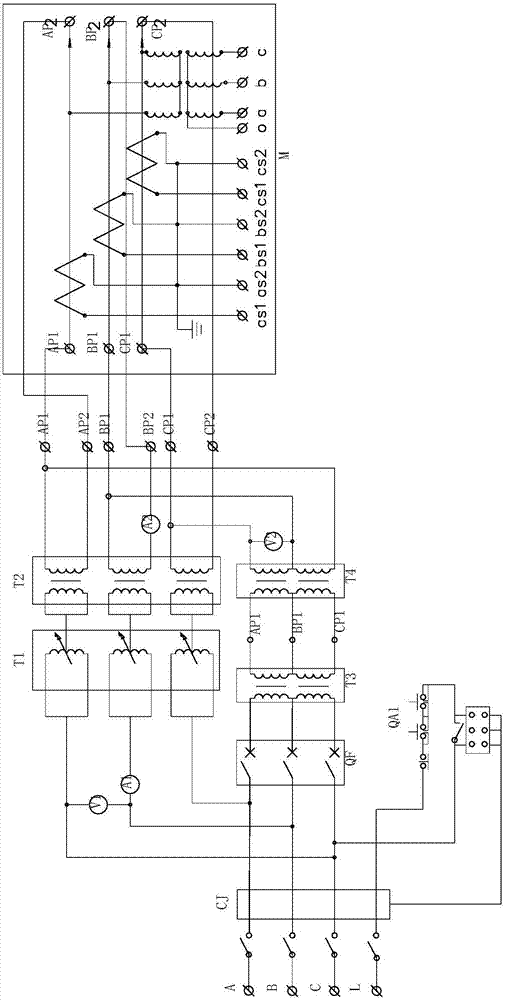

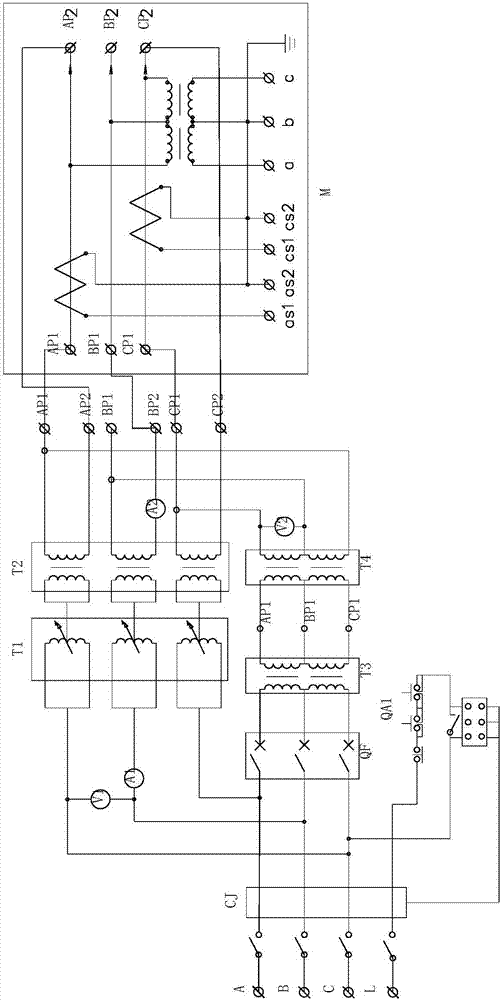

[0014] refer to figure 1 , figure 2 , a metering equipment load simulation device, including a simulation circuit composed of a current simulation branch and a voltage simulation branch in parallel, one end of the simulation circuit is connected to a three-phase four-wire 380V AC input, and the other end receives inspection equipment such as metering Equipment, energy meters and energy meter measurement analyzers, etc. The current emulation branch circuit includes a voltage regulator T1 and a high-voltage current booster T2 connected in sequence, and the voltage regulator T1 is provided with gear selection switches such as 10KV, 20KV, and 35KV. The voltage emulation branch circuit includes a circuit breaker QF, a step-down / regulator T3 and a booster T4 connected in sequence. An AC contactor CJ is connected between the simulation circuit and the 380V AC input.

[0015] In this embodiment, the output voltage of the booster T4 is 10kV, 20kV, 35kV, the output current of the hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com