Solanaceous attaching-grafting grafting machine and working method thereof

A sticking type, grafting machine technology, applied in grafting and other directions, can solve the problems that it is difficult for seedling enterprises to meet the requirements of automatic vegetable grafting machine seedlings, the per capita productivity is not high, and the cost performance is low, so as to improve work efficiency and grafting speed. , the effect of high grafting success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail in conjunction with the accompanying drawings and specific embodiments.

[0034] In order to facilitate a unified review of the various reference signs in the drawings of the specification, the unified description of the reference signs appearing in the drawings of the specification is as follows:

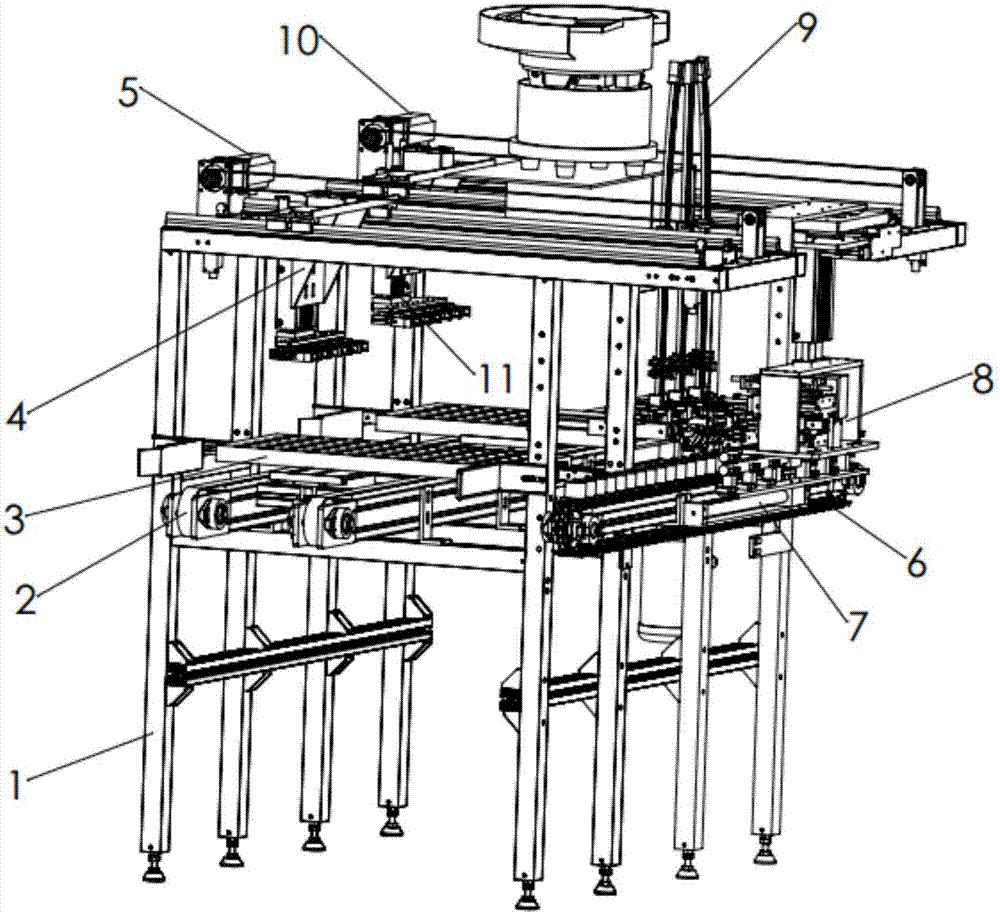

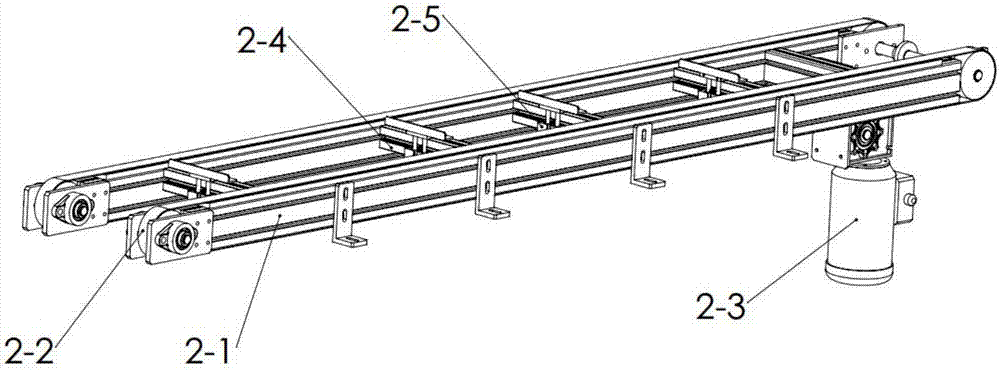

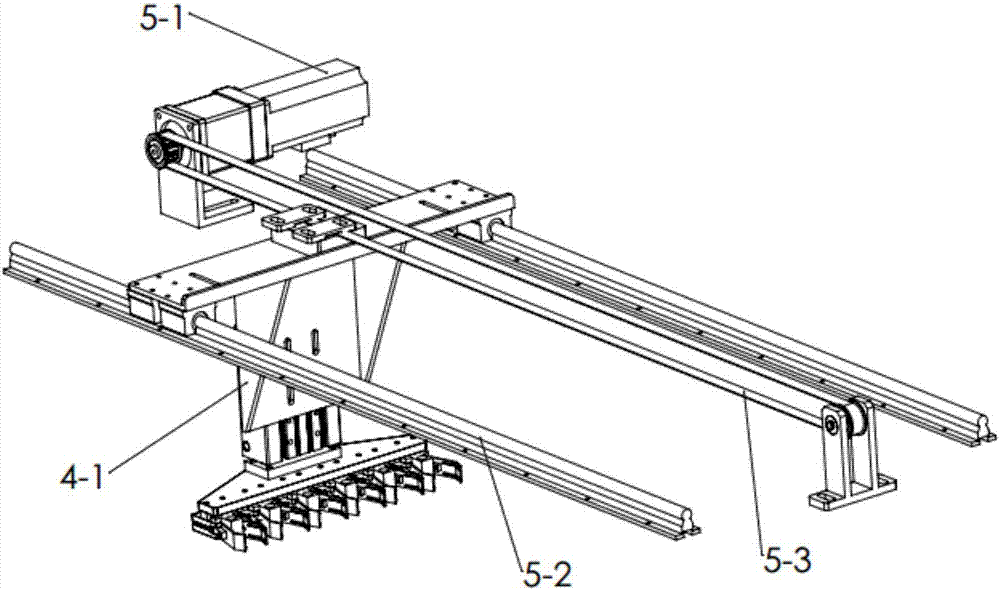

[0035] 1 is a frame, 2 is a tray conveying mechanism, 3 is a rootstock tray, 4 is a rootstock seedling loading mechanism, 5 is a seedling loading driving mechanism, 6 is a transfer mechanism, 7 is a scion adsorption mechanism, 8 is a grafting mechanism, and 9 is a For clamping mechanism, 10 is the replanting drive mechanism, 11 is the grafted seedlings replanted mechanism, 12 is the paper pot, 13 is the substrate block, 14 is the grafted seedling, 2-1 is the frame body, 2-2 is the synchronous belt assembly, 2 -3 is the first motor, 2-4 is the connecting block, 2-5 is the telescopic cylinder, 4-1 is the hanger, 4-2 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com