Oil smoke purifier capable of automatically sucking oil, forwardly and backwardly intercepting oil and collecting oil

A kind of oil fume purifier, forward and reverse technology, applied in the direction of oil fume removal, chemical instruments and methods, household heating, etc., can solve the problem that the oil fume purifier can not increase the air flow speed, the oil fume interception rate does not reach the ideal effect, and the impact area less problems, to achieve the effect of improving oil interception efficiency, large collision surface, and increased air volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the drawings and embodiments.

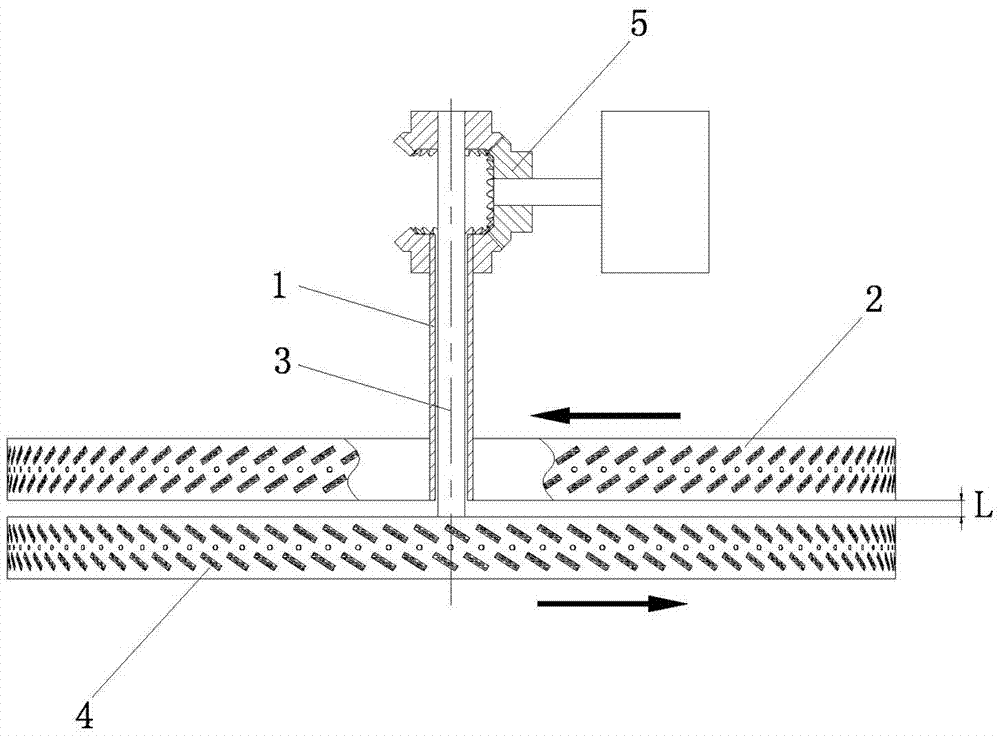

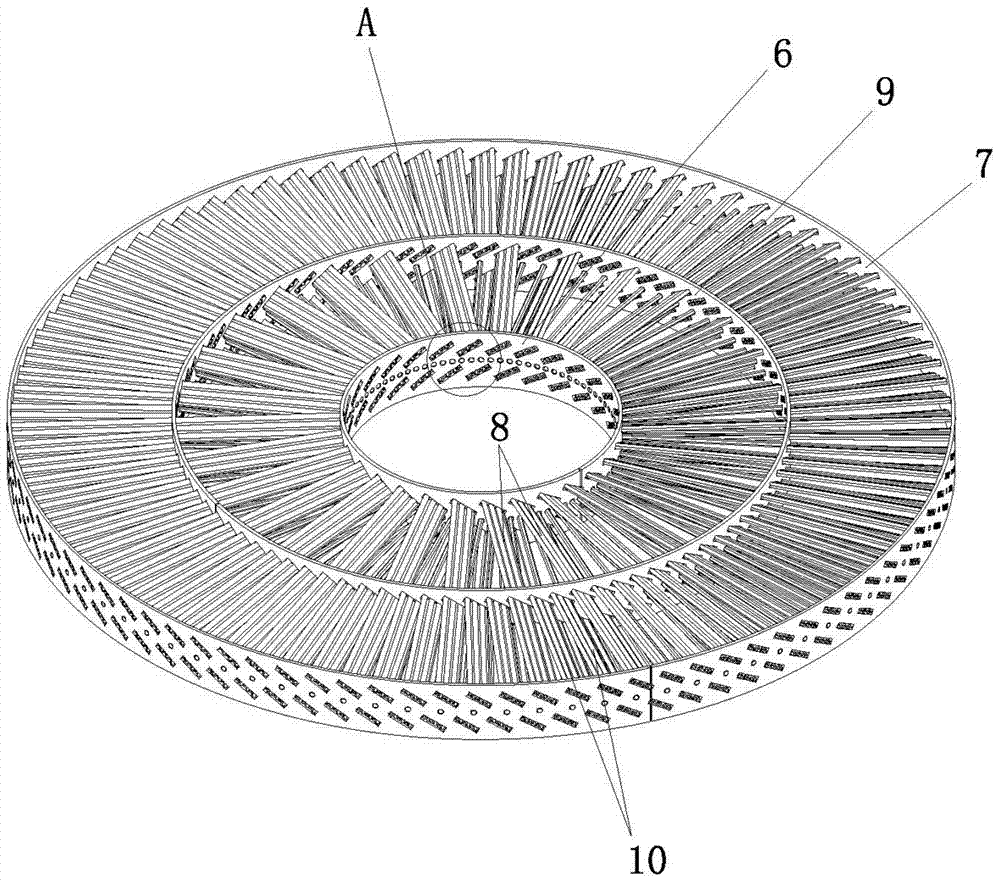

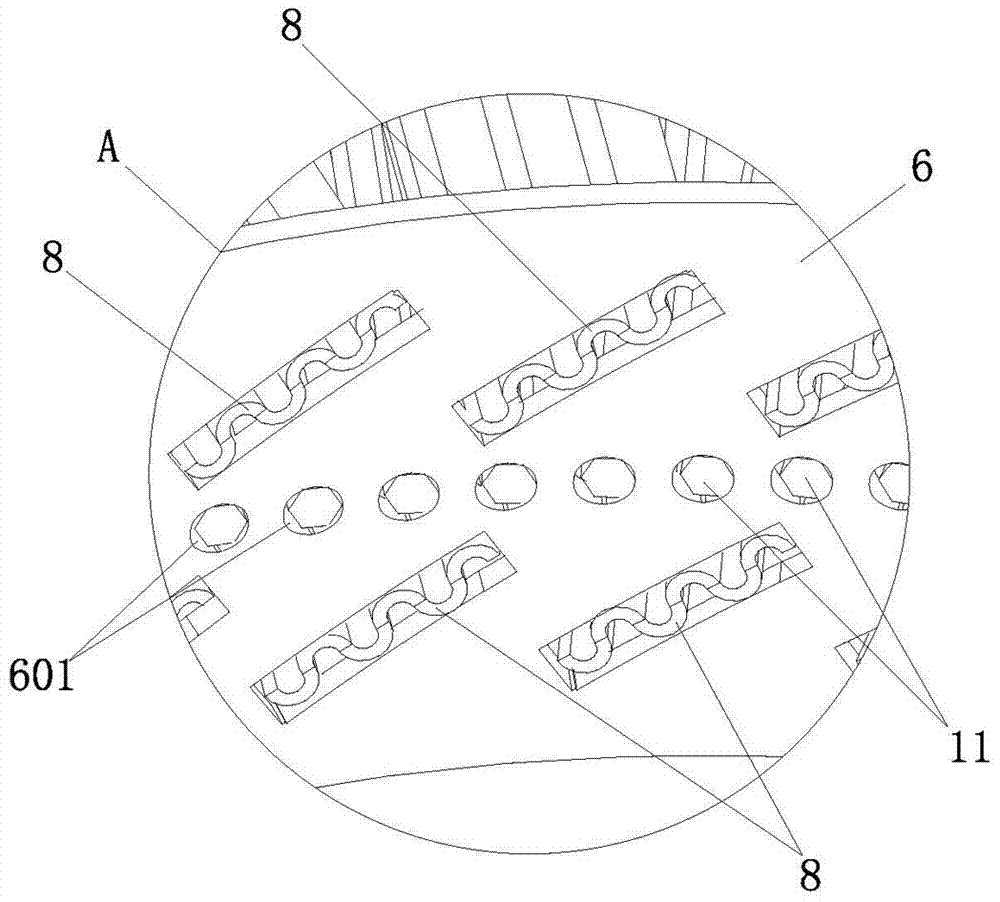

[0031] The first specific implementation is as Figure 1 to Figure 5 As shown, a self-priming forward and reverse intercepting oil-gathering oil fume purifier includes a hollow forward rotating shaft 1, one end of the forward rotating shaft 1 is equipped with a forward fume purifier 2, and the forward rotating shaft 2 is connected with The reverse shaft 3, one end of the reverse shaft 3 extends from the forward oil fume purifier 2 and is connected with the reverse oil fume purifier 4, and the other ends of the forward shaft 1 and the reverse shaft 3 are drivingly connected with a forward and reverse drive device 5; , On the basis of coaxial, the rotation speed is the same, but under the combined action of the two oil fume purifiers with opposite directions, the oil fume is formed into a high-speed cyclone flow, which repeatedly collides with the air guide and oil cut-of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com