Anti-splashing device and method used for welding sensor

An anti-spatter and sensor technology, used in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of affecting the welding seam detection accuracy, time-consuming, difficult to clean, etc. Small footprint effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, where the schematic embodiments and descriptions of the present invention are used to explain the present invention, but not to limit the present invention.

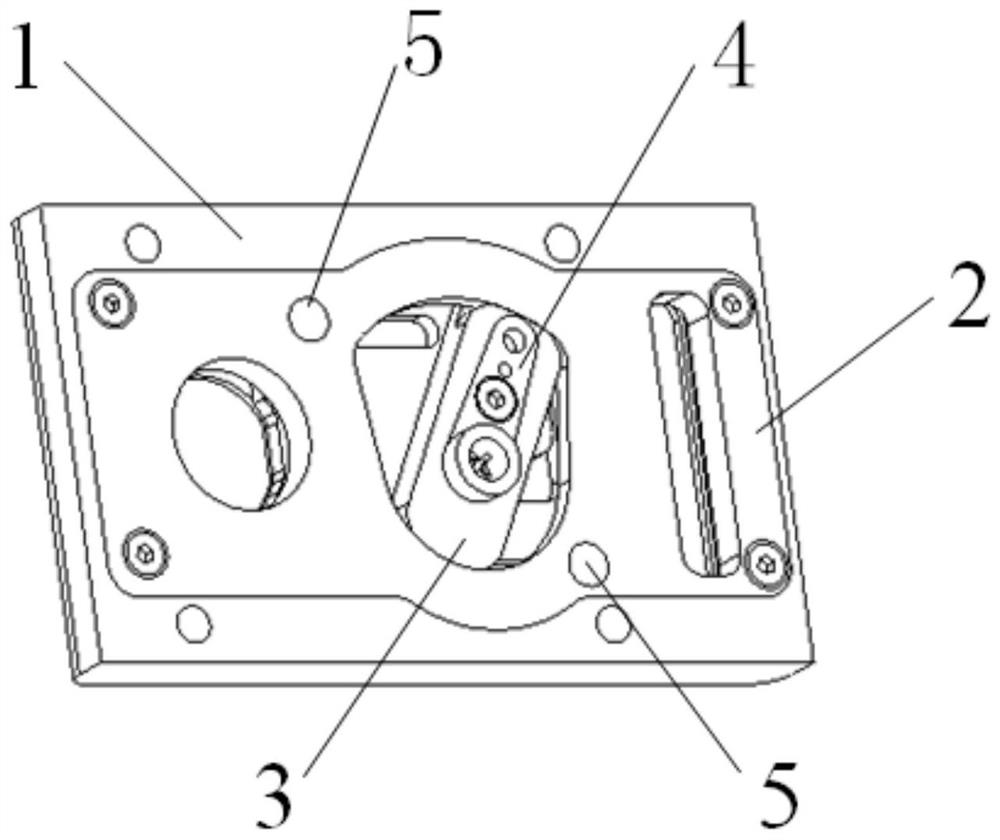

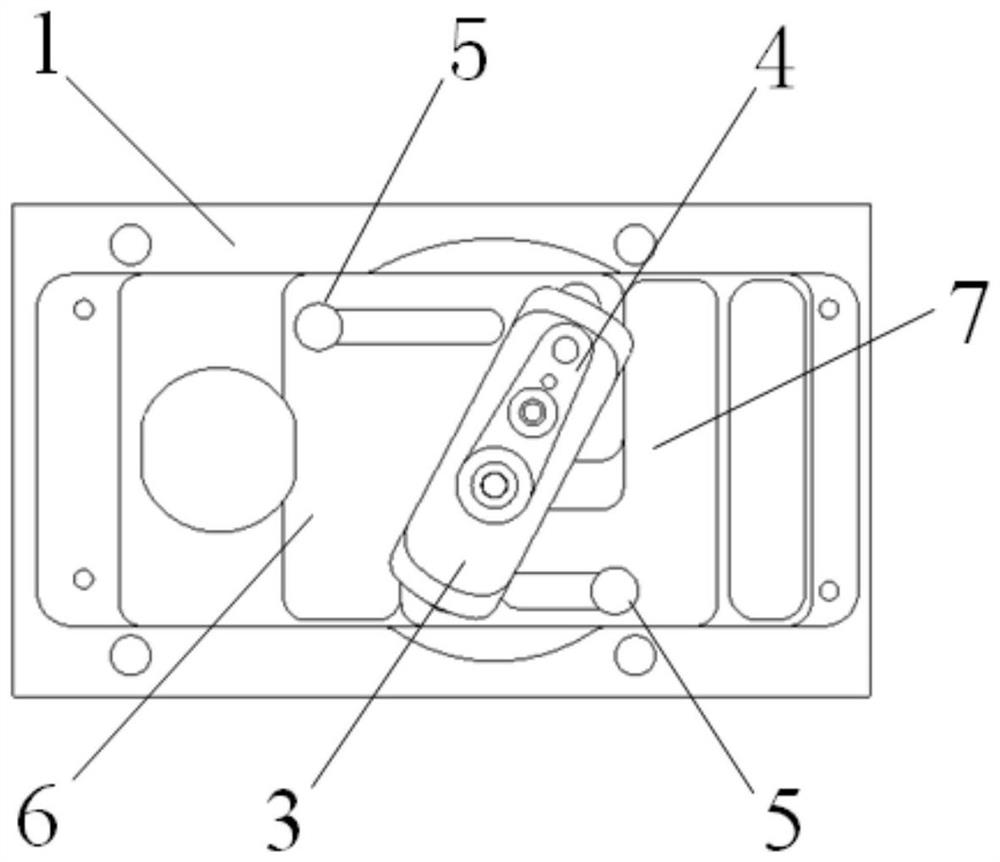

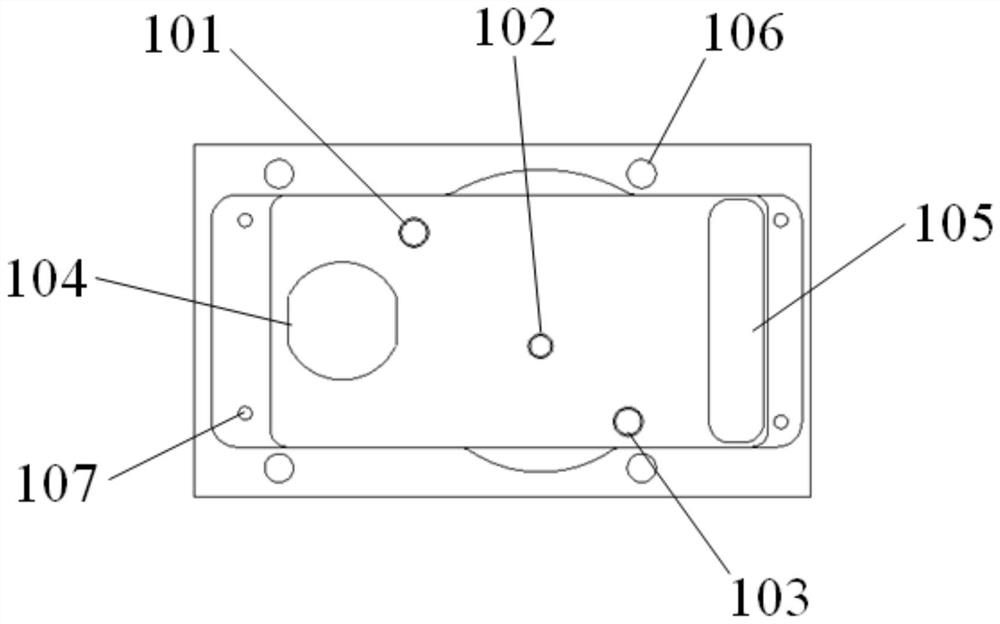

[0030] Such as figure 1 , figure 2 As shown, an anti-splash device for welding sensors provided by the embodiment of the present invention includes a base 1, a cover plate 2, a handle 3, a swing rod 4, a pin 5, a lens block 6 and a laser block 7; The base 1 is provided with a first lens light exit hole 104 and a first laser light exit hole 105; inside the first lens light exit hole 104 and the first laser light exit hole 105, the base 1 is provided with a lens stopper 6 and a laser stopper 7 , a rocking handle 3 and a swing rod 4 are arranged between the lens block 6 and the laser block 7; the swing rod 4 meshes with the output shaft gear of the steering gear, drives the rocker 3 to rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com