Disturbance type chemical liquid raw material equivalent mixing device

A chemical liquid and equal mixing technology, which is applied in the chemical industry, can solve the problems that the mixing degree of raw materials cannot meet the expected requirements, the automatic equal amount feeding cannot be realized, and the mixing effect of finished products is not good, so as to improve the mixing purity , Accelerate the filtration speed, avoid the effect of insufficient stirring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

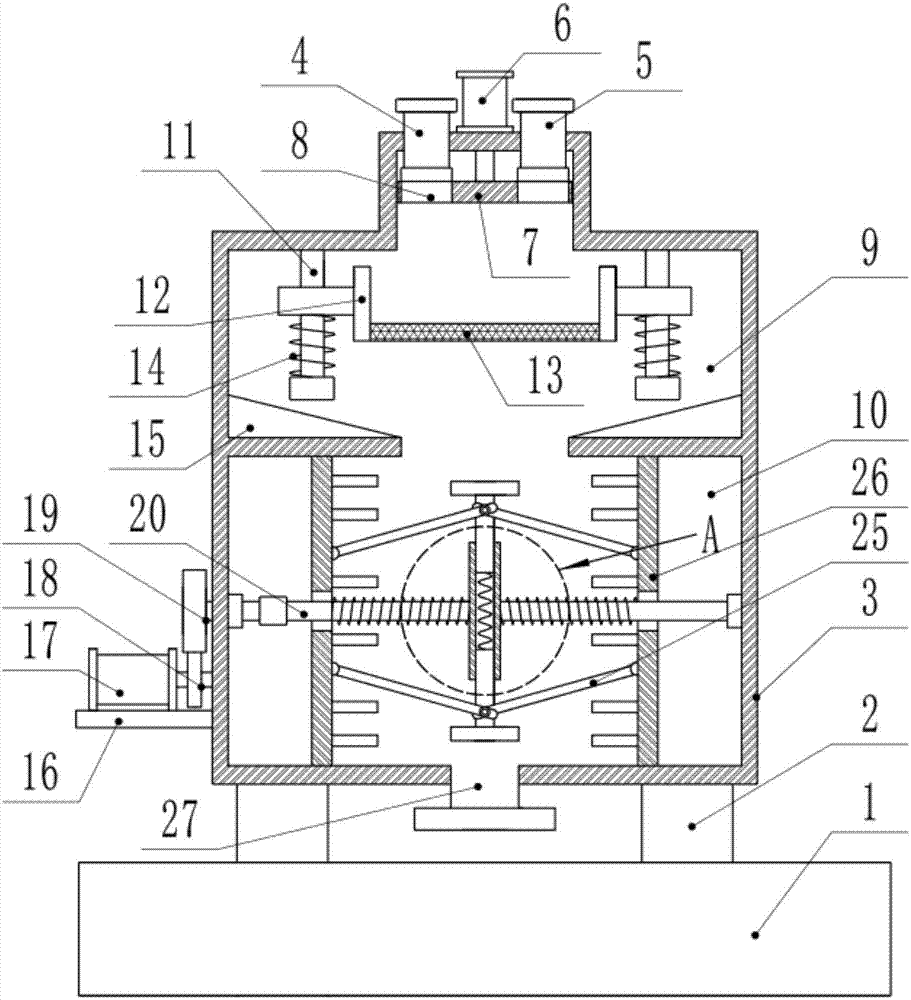

[0019] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

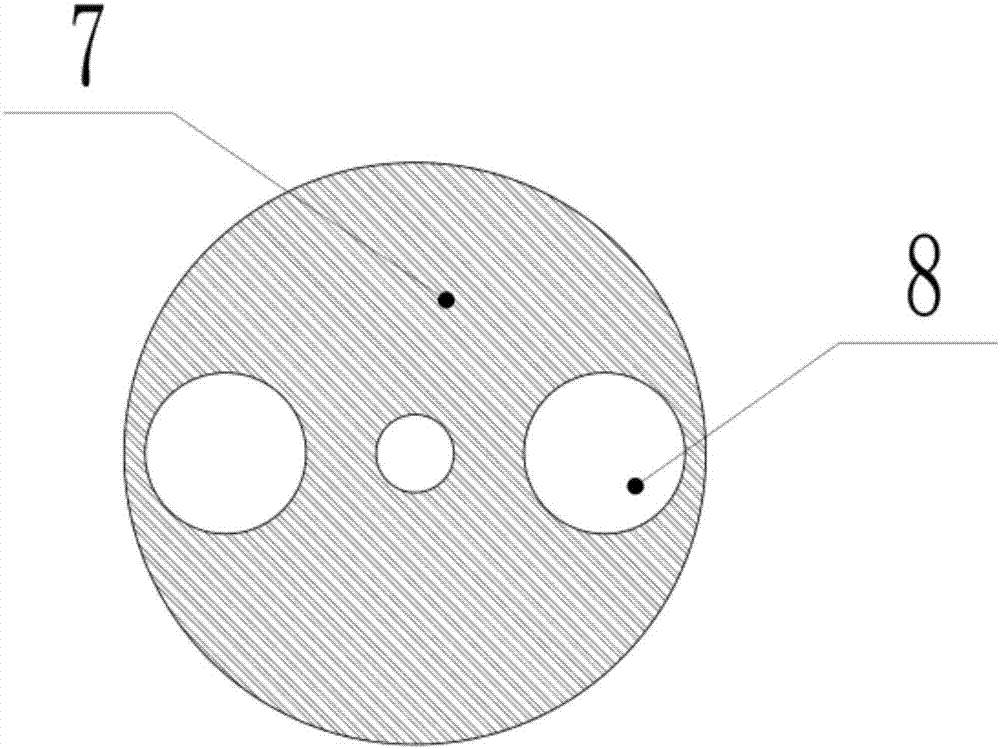

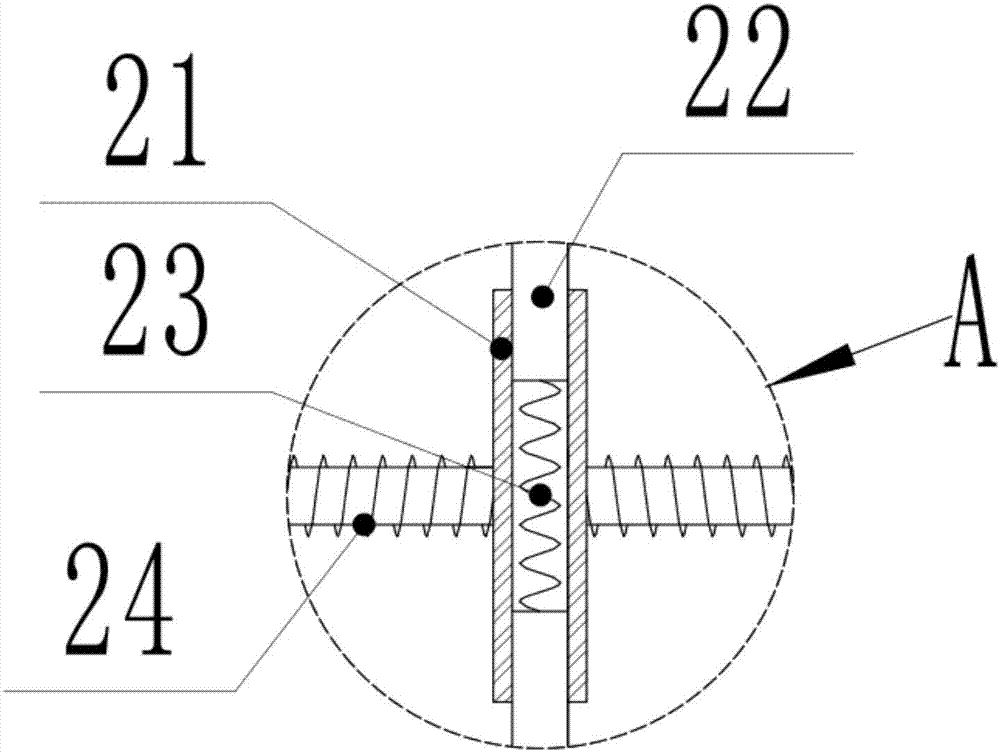

[0020] see Figure 1-3 , a turbulence type chemical liquid raw material equal mixing device, comprising a mixing box 3, an equal leak plate 7 and a spoiler 26, the base 1 is provided with a mixing box 3, and the mixing box 3 is connected to the base 1 There are legs 2, and the upper side of the mixing box 3 is respectively symmetrically provided with a feed port A4 and a feed port B5, and feed pipes are embedded in the feed port A4 and feed port B5, and the feed pipes are round pipes and are anti-corrosion material, one end of the delivery pipe stretches into the inside of the mixing box 3, and the upper side of the mixing box 3 is fixedly equipped with a driving motor 6, the output shaft of the driving motor 6 is vertically downward and stretches into the inside of the mixing box 3, and the driving motor The output shaft of 6 is connected with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com