Frame sealing adhesive and preparation method thereof as well as display panel and display device

A frame sealing glue and nanomaterial technology, applied in chemical instruments and methods, adhesives, epoxy resin glue, etc., can solve the problems of poor thermal conductivity, poor thermal stability, insufficient hardness, etc., to improve mechanical properties and improve compatibility. Sex, the effect of avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

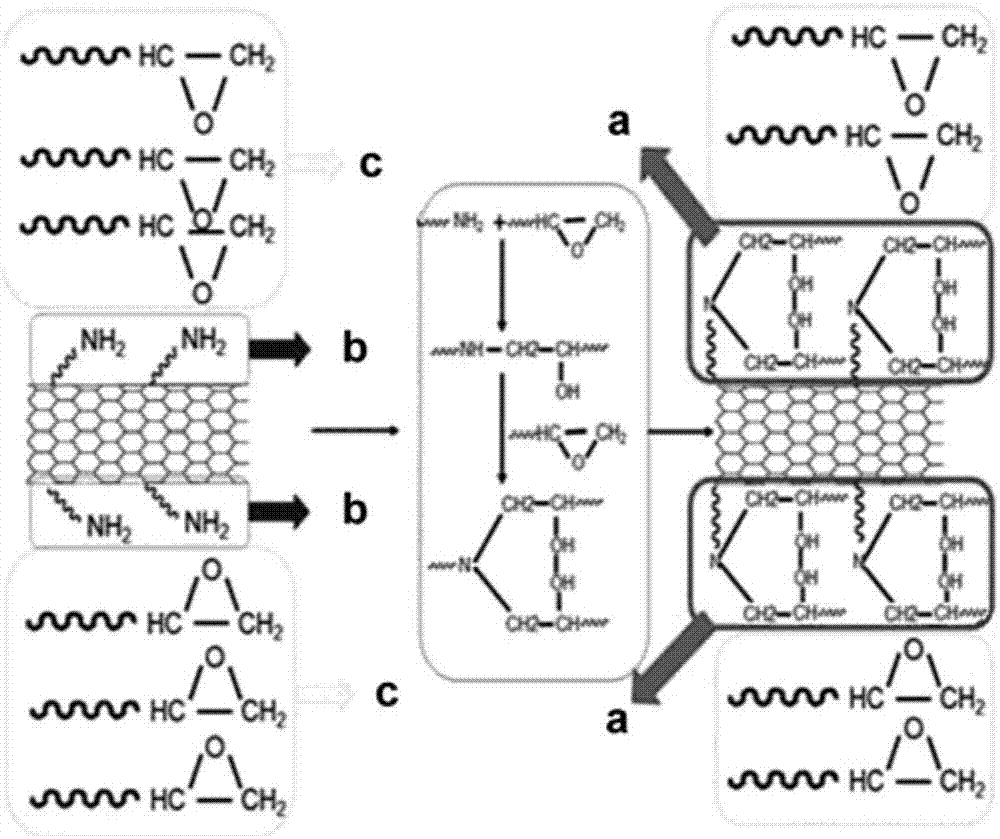

[0049] According to another aspect of the present invention, a method for preparing a frame sealant is provided, comprising the following steps: mixing an amine-modified nano material with a base component of the frame sealant, degassing, and curing to obtain a frame sealant.

[0050] Specifically, it can be: mix the amine-modified nanomaterials with the basic components of the sealant, and after ultrasonic treatment, stir at 500-1000rpm for 1-5h to obtain a homogeneous mixture, then add a defoamer and vacuumize at 50-70°C Remove air bubbles; when the air bubbles are completely removed, the mixture is cured to obtain the final product, frame sealant.

[0051] Wherein, the defoaming agent can be polyether modified silicon, polyether and polysiloxane, such as polyoxyethylene polyoxypropylene pentaerythritol ether, polyoxyethylene polyoxypropylene alcohol amine ether, polyoxypropylene glyceryl ether and Polyoxypropylene polyoxyethylene glyceryl ether, polydimethylsiloxane, etc. ...

Embodiment 1

[0066] (1) Mix 84 g of multi-walled carbon nanotubes with 100 mL of concentrated acid (H 2 SO 4 / HNO 3 , where H 2 SO 4 The concentration is 98wt%, HNO 3 The concentration is 65wt%) sonication for 15min to prevent clusters, and heated in a water bath at 60°C for 10h to generate a large number of carboxyl and hydroxyl groups; then the multi-walled carbon nanotubes and 1g SOCl 2 Heated in a water bath at 70°C for 24h, filtered and dried, and heated with 5g of N-(2aminoethyl)-1,2-ethylenediamine in a water bath at 120°C for 36h, and dried in a vacuum oven at 60°C After 48 hours, modified multi-walled carbon nanotubes were obtained.

[0067] (2) Mix 0.7g of modified multi-walled carbon nanotubes with 99.3g of sealant resin (9-20737 type sealant), and after ultrasonic treatment, stir with a strong mixer at 700rpm for 2h to obtain a homogeneous mixture, and then add Foaming agent polyoxyethylene polyoxypropylene pentaerythritol ether, vacuumize at 60°C to remove air bubbles. ...

Embodiment 2

[0069] In step (2), the amount of modified multi-walled carbon nanotubes is 1 g, the amount of sealing resin is 99 g, and the others are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com