Vehicle truss-type anti-descending girder structure and connection thereof

A truss type, beam structure technology, applied in the superstructure, substructure, superstructure sub-assembly and other directions, can solve the problems of easy to generate cavity echo, poor NHV performance, many installation bolts, etc., to achieve low manufacturing cost, rigidity Good, versatile effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings to facilitate a clearer understanding of the present invention, but the present invention is not limited to the following specific embodiments.

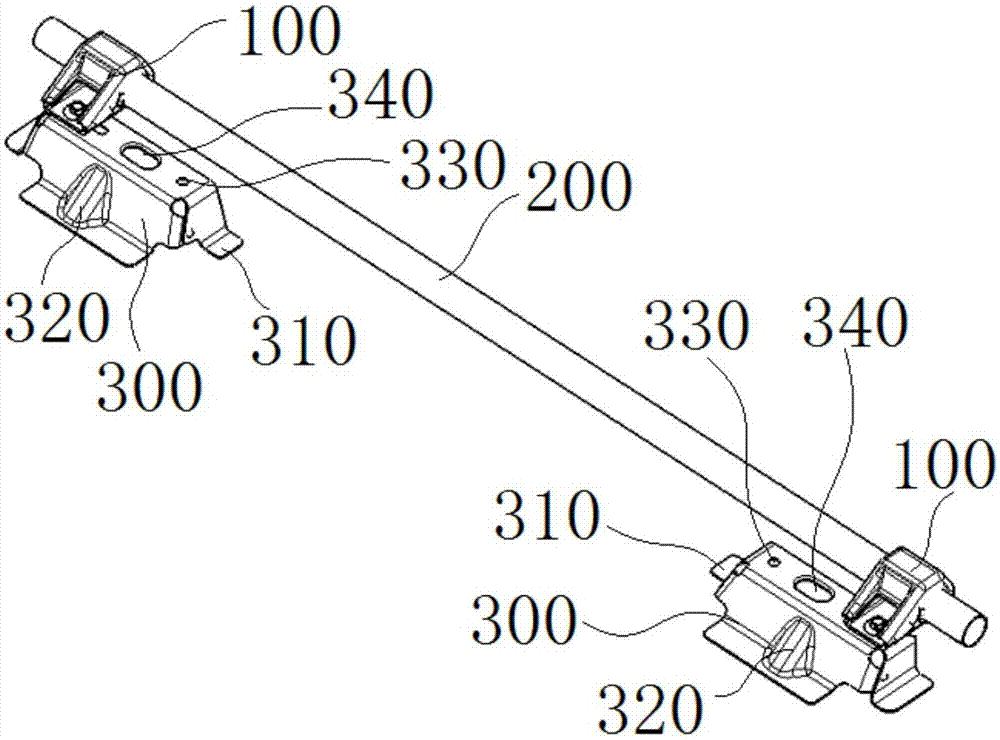

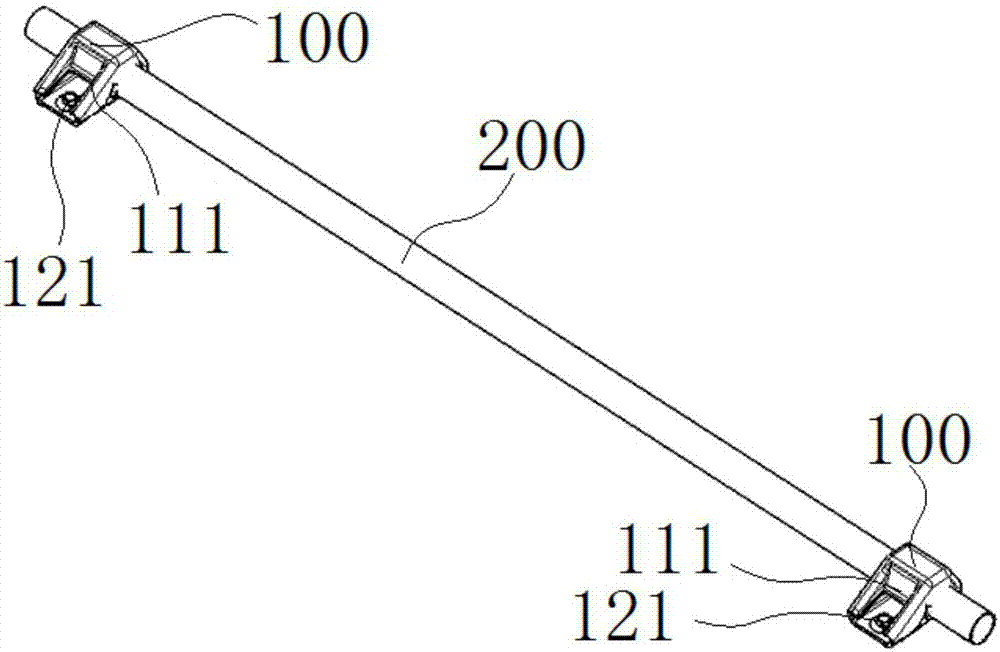

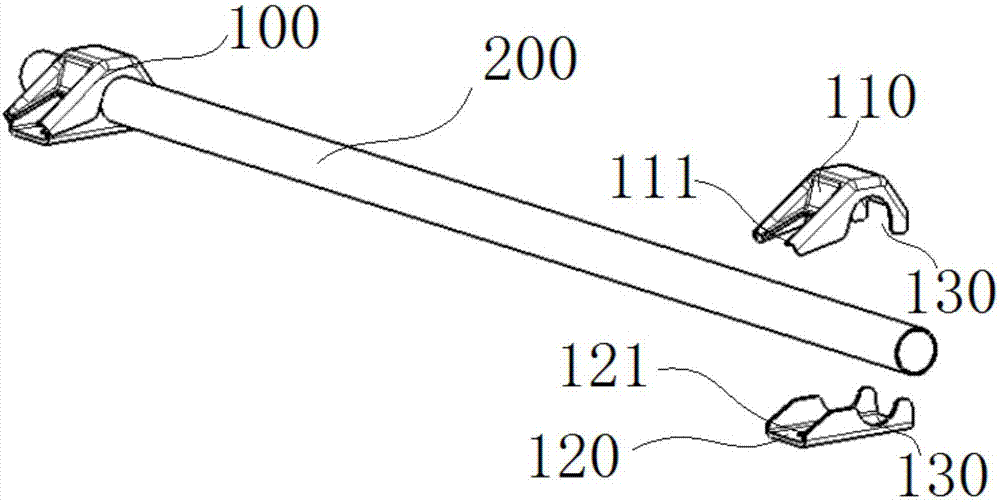

[0025] Such as figure 1 As shown, an automobile truss-type anti-submersion beam structure of the present invention includes a support tube 200, a lock structure 100 and a fixed base 300, the two ends of the support tube 200 are fixedly connected to the lock structure 100, and the lock structure 100 is connected to Fix the base with 300 bolts. Among them, in order to reduce the manufacturing cost of the support pipe 200, a hollow steel pipe with light weight and high strength is selected, and the hollow steel pipe only needs to be cut to a suitable length during processing for subsequent installation and connection.

[0026] Combining the above schemes, such as figure 1 , figure 2 , image 3 and Figure 4 As shown...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com