Goods recycle case capable of being assembled and restored and internally provided with air bag system

A turnover box and airbag technology, applied in the directions of internal accessories, transportation and packaging, bottle/can parts, etc., can solve the problems of many times of inflation, reduce volume, increase the gap between the empty space and the goods in the turnover box, and simplify the operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

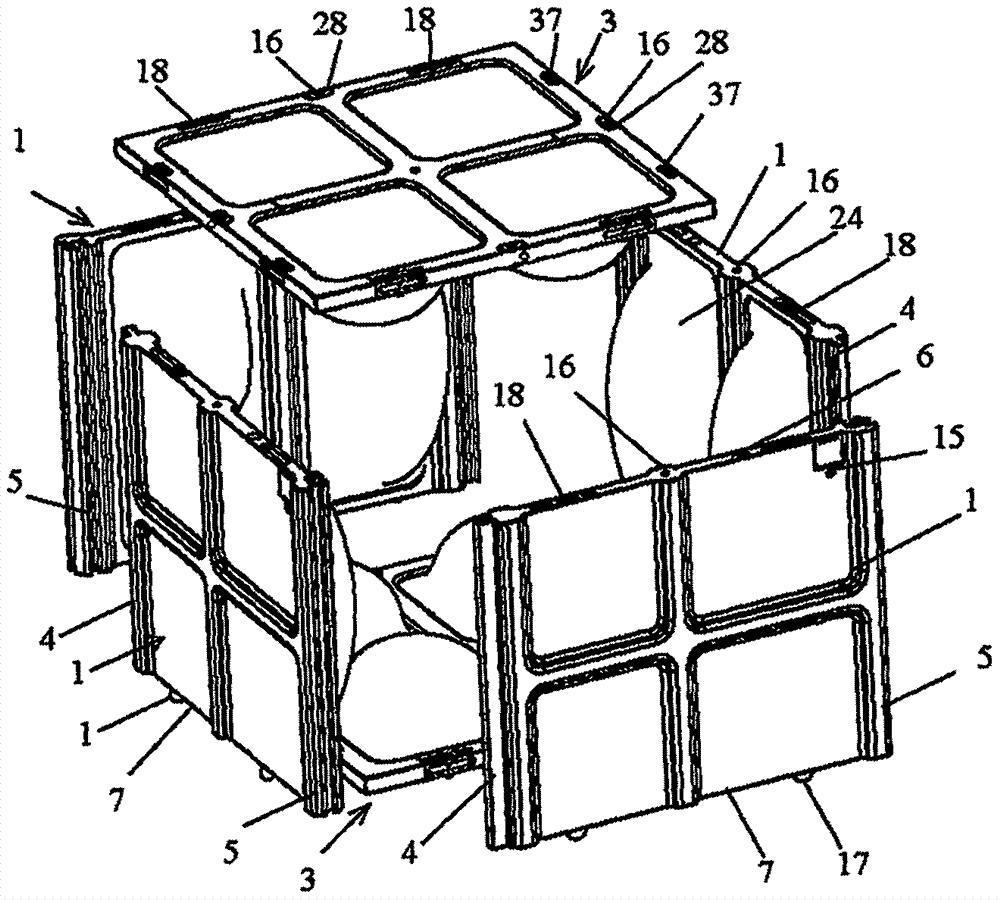

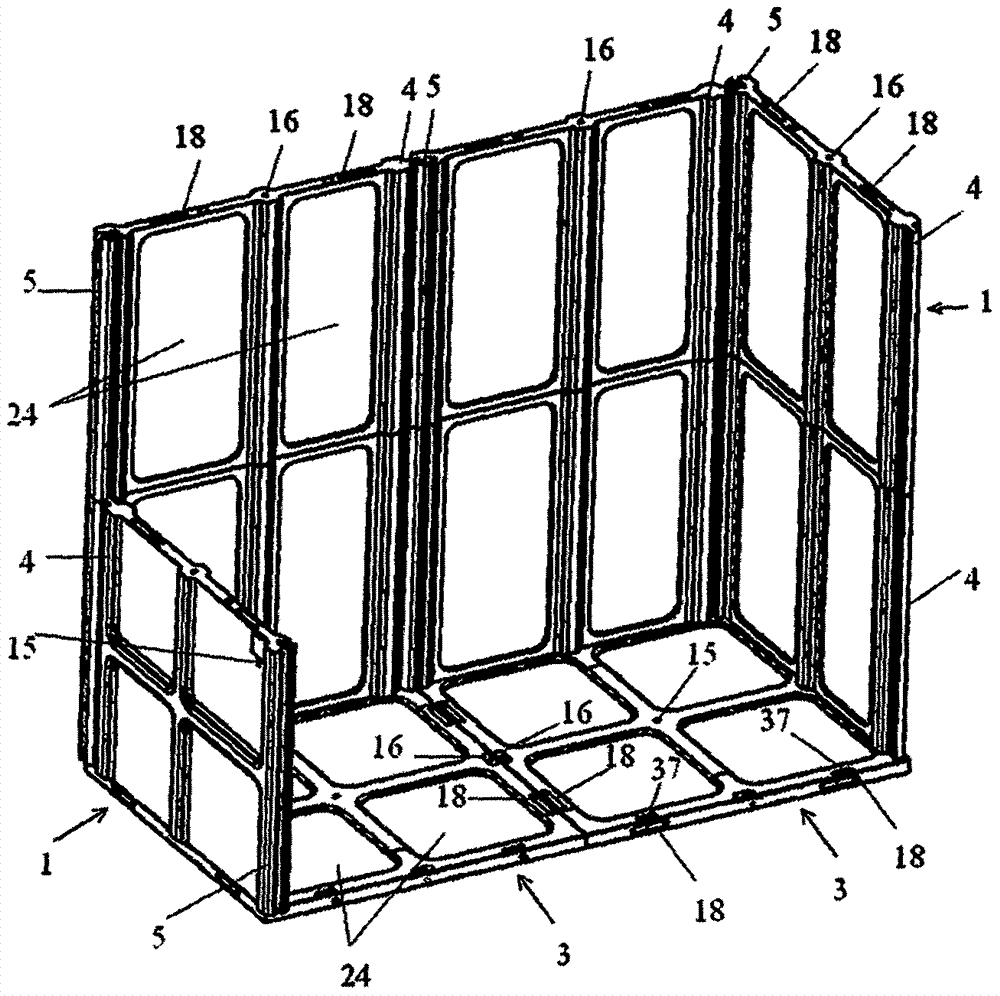

[0071] Embodiment 1. Cargo turnover box that can be dismantled and restored and has an airbag system inside

[0072] Such as Figure 1-15 , a cargo turnover box that can be dismantled and restored and has an airbag system inside. The turnover box includes splicing side panels 1 and upper and lower cover panels 3 that are snapped together and can be snapped together again after being removed and restored. It is characterized in that: in the turnover box A spliced airbag system 23 is provided; the spliced side panel 1 and the upper and lower cover panels 3 are respectively provided with a combination airbag 2, and the combined airbags 2 of the spliced side panel 1 and the upper and lower cover panels 3 are connected to form the spliced airbag system 23 of the turnover box;

[0073] Splicing side panel 1 and upper and lower cover panels 3 choose ABS resin, or modified high-impact polypropylene HIPP, or nano-silica nanoSiO2 composite material or L-PLA, or bamboo powder / bas...

Embodiment 2

[0083] Embodiment 2. Cargo turnover box that can be dismantled and restored and has an airbag system inside

[0084] Such as Figure 1-15 , such as the cargo turnover box that can be dismantled and restored and has an airbag system in it in Example 1, wherein the snap-in connection structure is selected as follows:

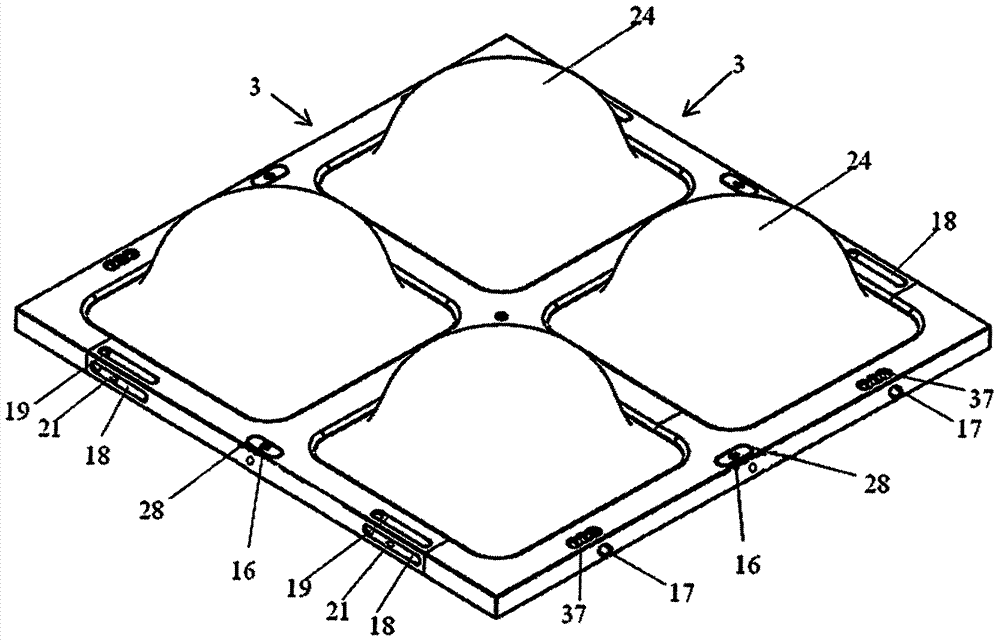

[0085]The snap-in connection structure includes two components, a spherical-shaped snap-in tenon protrusion 17 and a snap-in short mortise 18, and the two ends of the snap-in short mortise 18 are provided with a spherical-segment shaped snap-in tenon protrusion 17's slot card entrance 19, between the two slot slot card entrances 19 is a slot sliding section 20, the slot slot card entrance 19 is wider than the slot sliding section 20, and the width of the slot slot card entrance 19 is the same as that of the spherical segment-shaped sliding tenon The maximum width of the protrusion 17 is matched, and the cross-sectional width of the short groove in the mortise sli...

Embodiment 3

[0086] Embodiment 3. Cargo turnover box that can be dismantled and restored and has an airbag system inside

[0087] Such as Figure 1-15 , such as the cargo turnover box that can be dismantled and restored and has an airbag system in it in Example 1, wherein the snap-in connection structure is selected as follows:

[0088] The snap-in connection structure includes a spherical-segment-shaped tenon protrusion 17 and a porous connecting mortise 37, each socket of the multi-hole connecting trough 37 has the same shape and size and communicates, and the spherical-segment-shaped tenon protrusion 17 and each socket of the porous communication socket 37 are closely fitted with a clamping structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com