Light source module for DLP micro projector ray machine, ray machine and DLP projector

A light source module and micro-projection technology, applied in the field of DLP projectors and optical machines, can solve the problems of low energy utilization of light sources, affecting the volume of projectors, cost, uncontrollable tolerances, etc., to improve projection uniformity and projection quality , Improve energy utilization, reduce the effect of positioning error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

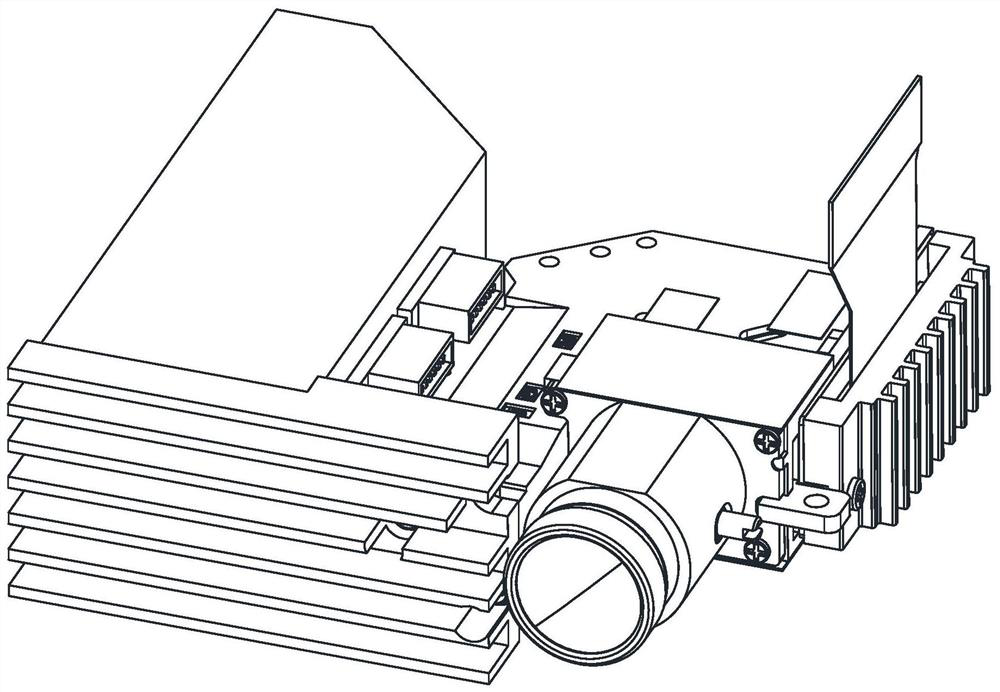

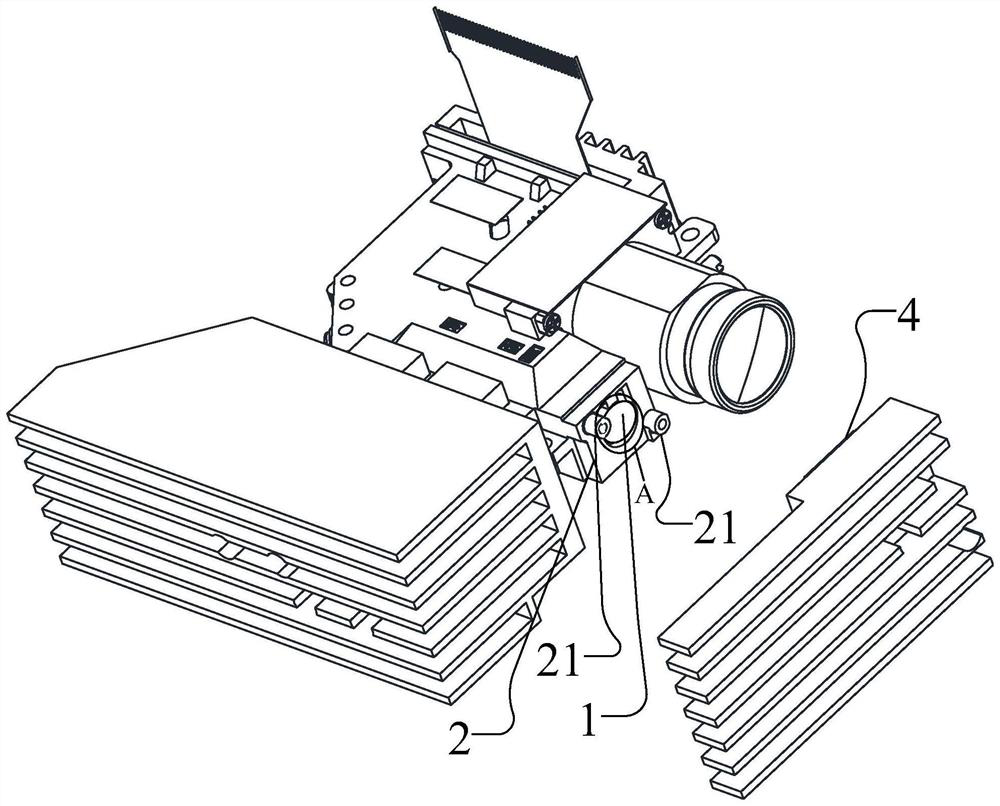

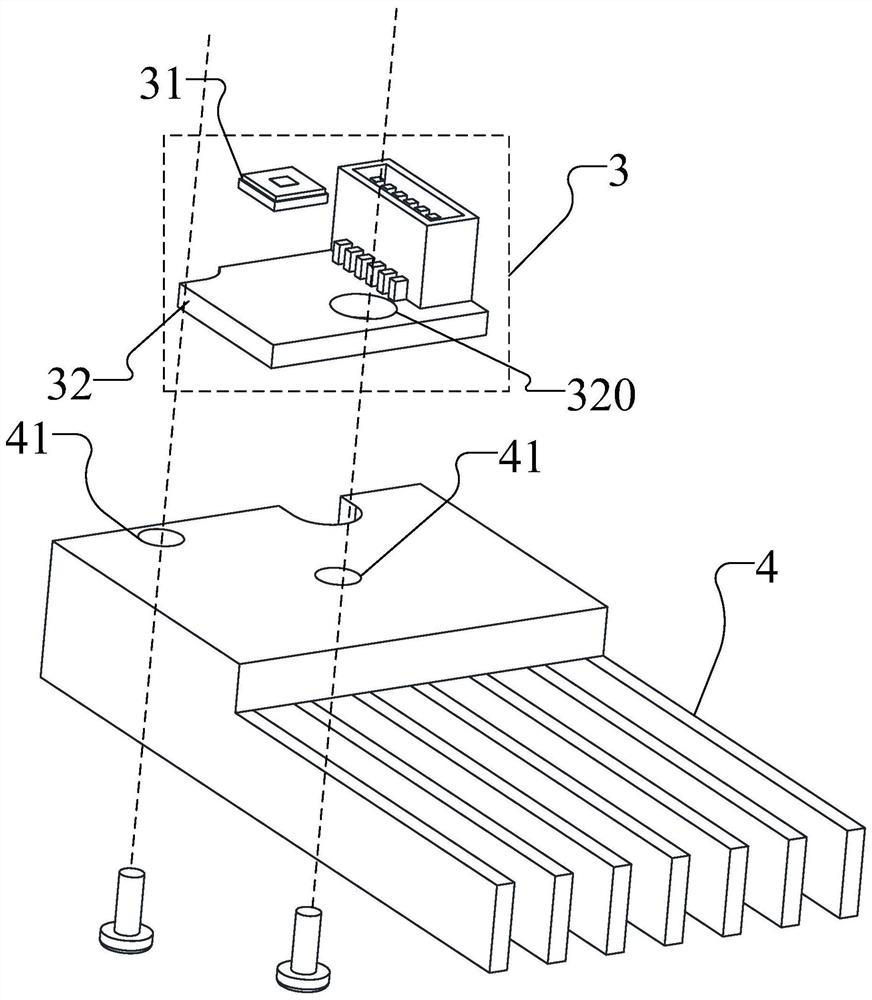

[0040] In a DLP projector, in order to improve the energy utilization rate of the light source, improve the projection uniformity and the projection quality, this embodiment discloses a light source module for a DLP micro-projector optical machine and an optical machine with it, and a DLP projection projector. instrument, DLP projector includes light machine, please refer to figure 1 , figure 2 with image 3 ,in, figure 1 It is a schematic structural diagram of a DLP projector optical machine disclosed in this embodiment, figure 2 It is a schematic diagram of the state of a DLP projector disclosed in this embodiment after the optical machine separates a light source module, image 3 It is a schematic diagram of an explosion of a light source module disclosed in this embodiment. In a specific embodiment, the optical machine includes a collimator lens 1, a collimator lens mount 2 and a light source module without reference numerals, wherein the light source module It inclu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com