Elevator safety tongs with high safety performance

A technology of safety performance and safety gear, which is applied in the direction of elevators, transportation and packaging, etc., can solve problems such as unbalanced braking force, lateral deviation, and affecting the balanced transmission of braking force, so as to eliminate elastic bias load, improve safety performance, and brake good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

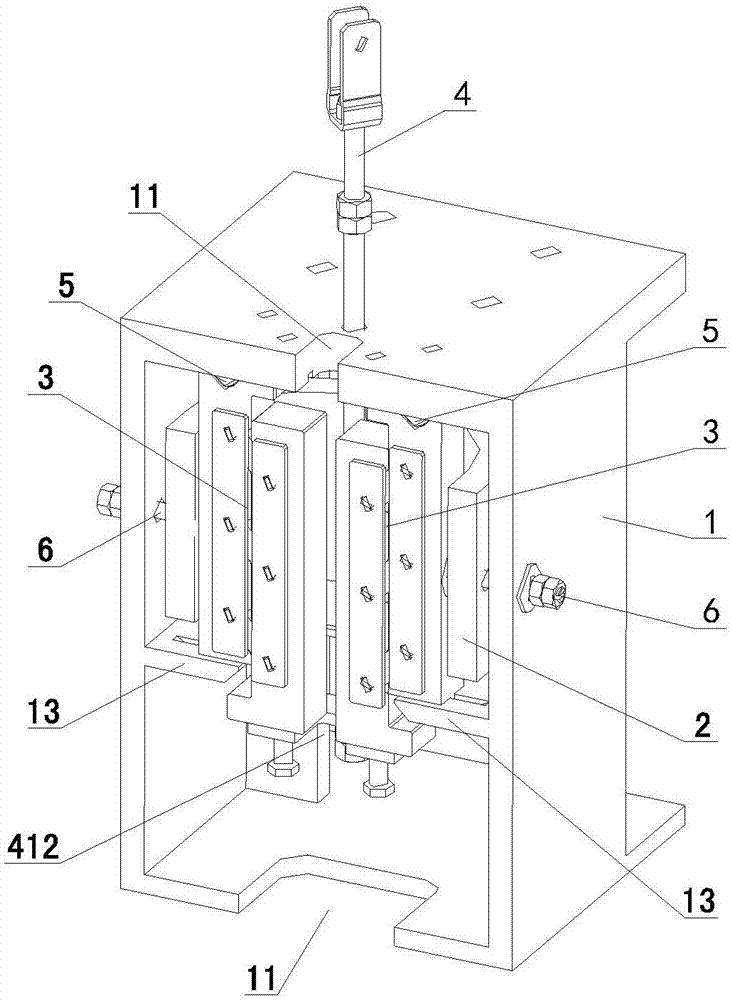

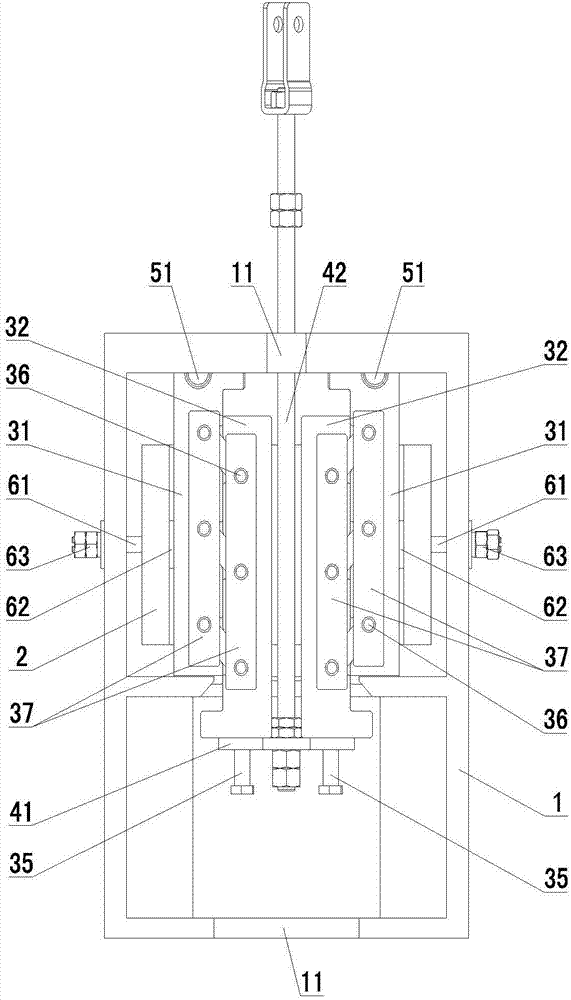

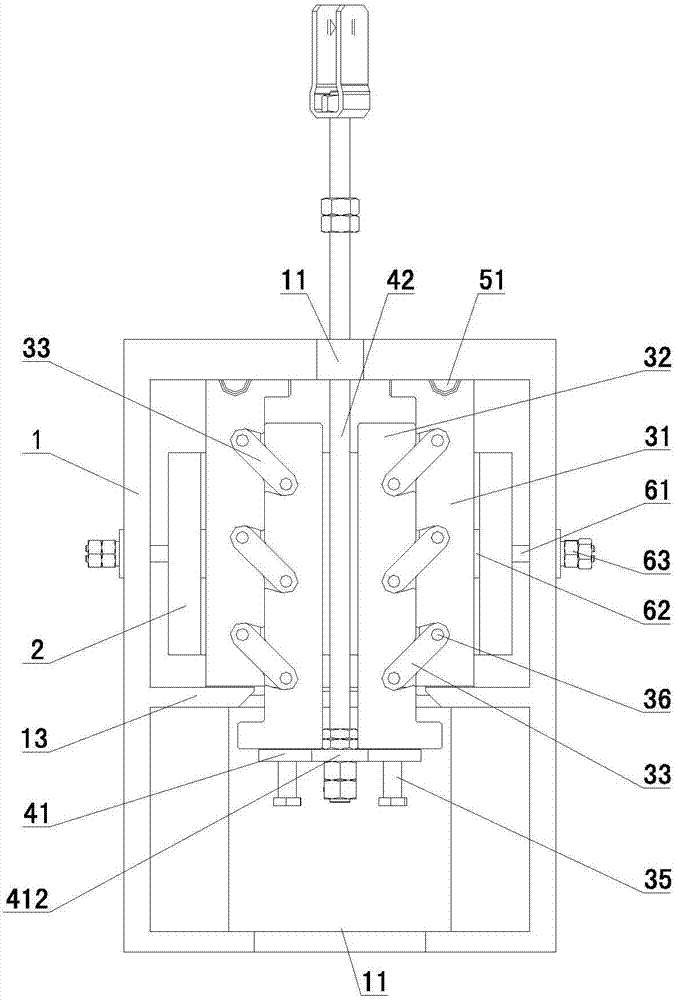

[0020] Such as Figure 1-Figure 8 As shown, the elevator safety gear with high safety performance of the present invention comprises a clamp base 1, a U-shaped spring 2 arranged in the clamp base 1, two groups of swinging clamping mechanisms 3 arranged symmetrically in the opening of the U-shaped spring 2 and A group of lifting mechanisms 4 that are jointly arranged on two groups of swinging clamping mechanisms 3, and the clamp base 1 is provided with an opening 11 that is convenient for the elevator guide rail to pass between the two groups of swinging clamping mechanisms 3. Two sets of swing clamping mechanisms 3 provide inward pressing force through U-shaped springs 2 .

[0021] Specifically, the swing-type clamping mechanism 3 includes a guide block 31, a clamp block 32 and a swing arm 33. The swing arm 33 is arranged inclined from outside to inside and from top to bottom, and its upper end passes through a rotating shaft 36 to connect with the guide block. 31 is rotatabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com