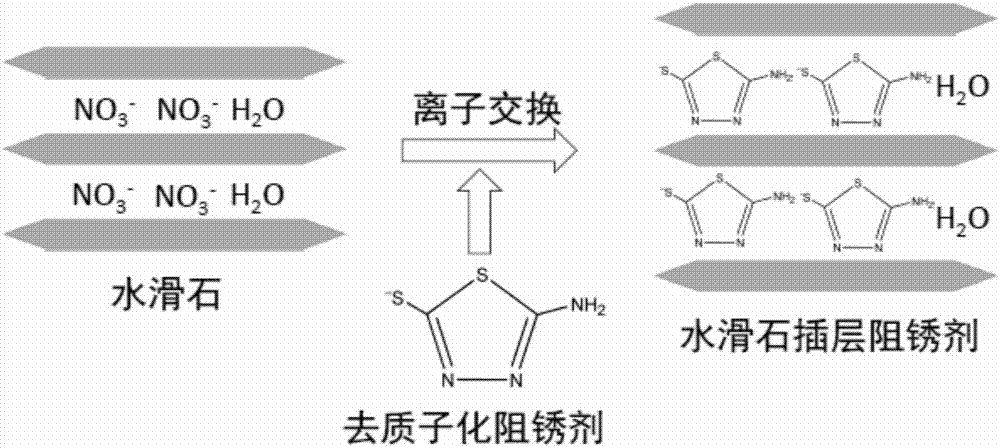

Hydrotalcite intercalation 2-amino-5-sulfhydryl-1,3,4-thiadiazole corrosion inhibitor and application thereof

A rust inhibitor and thiadiazole technology, applied in the field of rust inhibitors, can solve the problems of destroying the ecological environment, loss of rust inhibitors, single function, etc., and achieve the effects of small environmental side effects, corrosion prevention, and low dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Preparation of hydrotalcite intercalated 2-amino-5-mercapto-1,3,4-thiadiazole rust inhibitor.

[0037] The first step: Synthesis of zinc aluminum hydrotalcite, the reaction is as follows:

[0038] Zn(NO 3 ) 2 ·6H 2 O+2NaOH=Zn(OH) 2 ↓+2NaNO 3 +6H 2 O(1)

[0039] Al(NO 3 ) 3 9H 2 O+3NaOH=Al(OH) 3 ↓+3NaNO 3 +9H 2 O (2)

[0040] 0.67Zn(OH) 2 +0.33Al(OH) 3 +mH 2 O+0.33NaNO 3

[0041] =[Zn 0.67 Al 0.33 (OH) 2 ][(NO 3 ) 0.33 mH 2 O]+0.33NaOH (3)

[0042] First, 14.85g Zn(NO 3 )2·6H 2 O and 9.38g Al(NO 3 )3·9H 2 O was dissolved in 100mL distilled water to obtain mixed salt solution A; then 25.5g NaNO 3 Dissolve in 200mL distilled water to obtain solution B; then dissolve 8g NaOH in 100mL distilled water to obtain alkaline solution C.

[0043] Next, slowly add solution A to solution B dropwise, and at the same time add dropwise alkaline solution C to maintain the pH of the mixed system = 10±0.5, during which the mixed system is vigorously stirred, a...

Embodiment 2

[0052] Obtain the antirust compound of above-mentioned embodiment and measure its antirust efficiency, specifically:

[0053] Conditions: The experimental material is carbon steel (Fe: 99.5%, Mn: 0.4-0.5%, C: 0.1-0.2%), and the effective rust inhibitor component is zinc-aluminum hydrotalcite intercalation 2-amino-5- Mercapto-1,3,4-thiadiazole rust inhibitor, the medium is 3.5% sodium chloride solution, the dosage is 1L, the effective content of rust inhibitor added is 0.5g, the temperature is 25°C, pH=11.5, and the immersion time is 60 days.

[0054] According to the above-mentioned measurement method, the rust-inhibiting efficiency obtained through the experimental test is 89.1% in weight loss, 89.7% in electrochemical impedance spectroscopy, and 90.5% in the dynamical polarization curve, indicating that the compound is a rust inhibitor with low dosage and high efficiency.

Embodiment 3

[0056] Conditions: The experimental material is carbon steel (Fe: 99.5%, Mn: 0.4-0.5%, C: 0.1-0.2%), and the effective rust inhibitor component is zinc-aluminum hydrotalcite intercalation 2-amino-5- Mercapto-1,3,4-thiadiazole rust inhibitor, the medium is 3.5% sodium chloride solution, the dosage is 1L, the effective content of rust inhibitor added is 1g, the temperature is 25°C, pH=11.5, and the immersion time is 60 sky.

[0057] According to the above-mentioned measurement method, the rust-inhibiting efficiency obtained through the experimental test is 91.5% for weight loss, 92.3% for electrochemical impedance spectroscopy, and 93.4% for potentiodynamic polarization curve, indicating that the compound is a rust inhibitor with low dosage and high efficiency.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap