Sound barrier, catenary and road cut supporting structure into one unit of high-speed railway

A high-speed railway, trinity technology, applied in the direction of roads, buildings, overhead lines, etc., can solve the problem of limited land use scope, and achieve the effect of reducing investment, saving land, and novel structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below through specific embodiments in conjunction with the accompanying drawings.

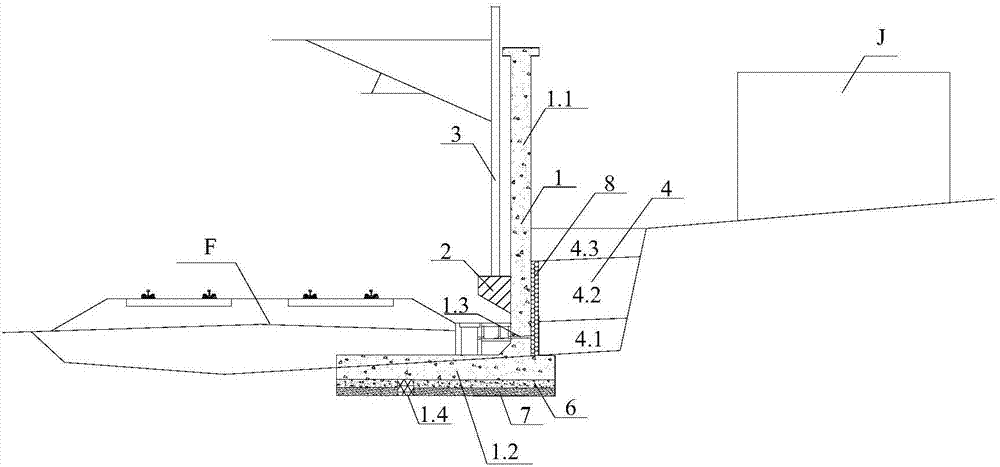

[0010] refer to figure 1 , the trinity structure of the high-speed railway sound barrier, catenary and cutting support of the present invention includes the sound barrier and the catenary support 3 arranged between the high-speed railway cutting F and the residential area J. The sound barrier is a cantilever sound barrier retaining wall 1 with an L-shaped section, which has an upright cantilever 1.1 and a bottom plate 1.2 extending into the high-speed railway cutting F. On the inner side wall of the cantilever 1.1, corbels 2 are arranged at intervals along the line extension direction, and catenary pillars 3 are arranged on the corbels 2 . A backfill layer 4 is provided on the outside of the cantilever sound barrier retaining wall 1 . The cantilever sound barrier retaining wall 1 can be used as the supporting structure of the high-speed r...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap