Pressure holding tee

A three-way, pass-through technology, applied in the direction of pipeline supports, branch pipelines, mechanical equipment, etc., can solve the problems of high requirements on pipeline surface, inability to realize the connection of two annular pressure test spaces, low operation efficiency, etc. The effect of sealing effect and pressure test efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. And the features in the embodiments can be combined with each other.

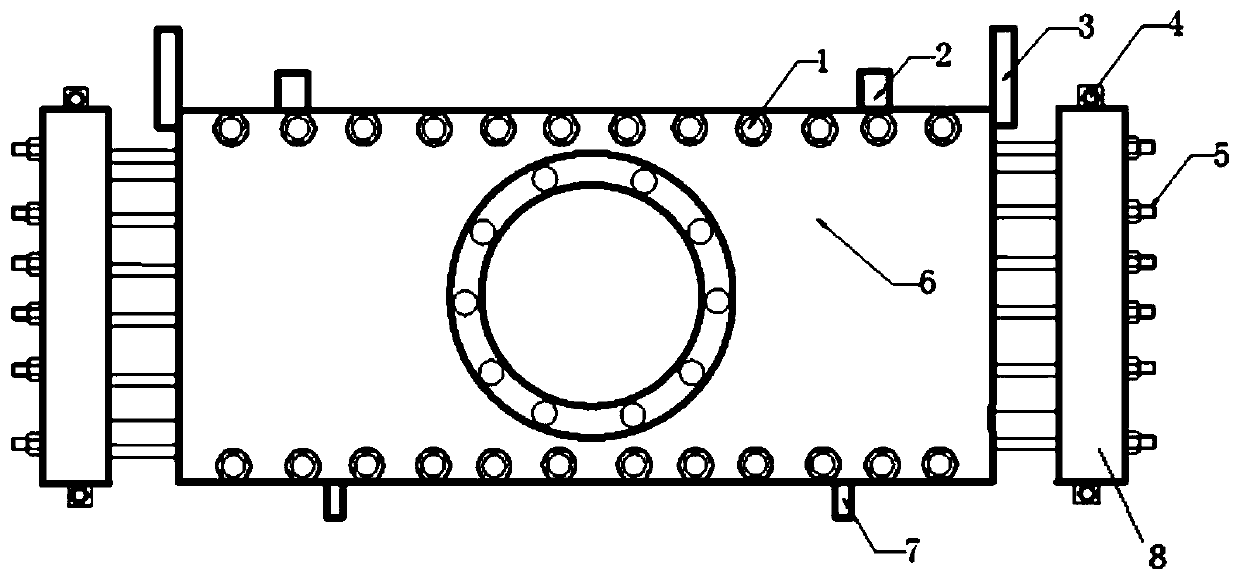

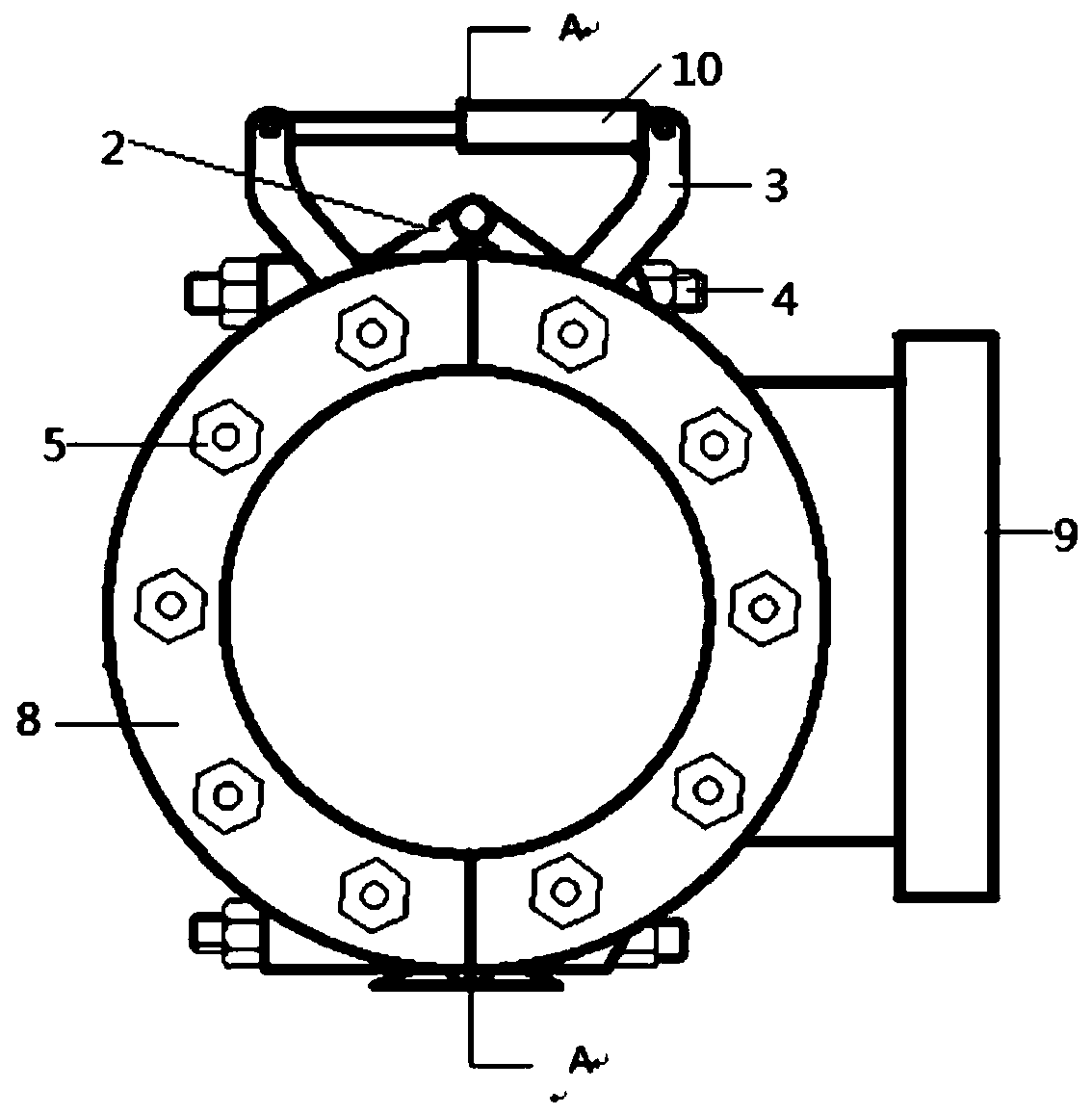

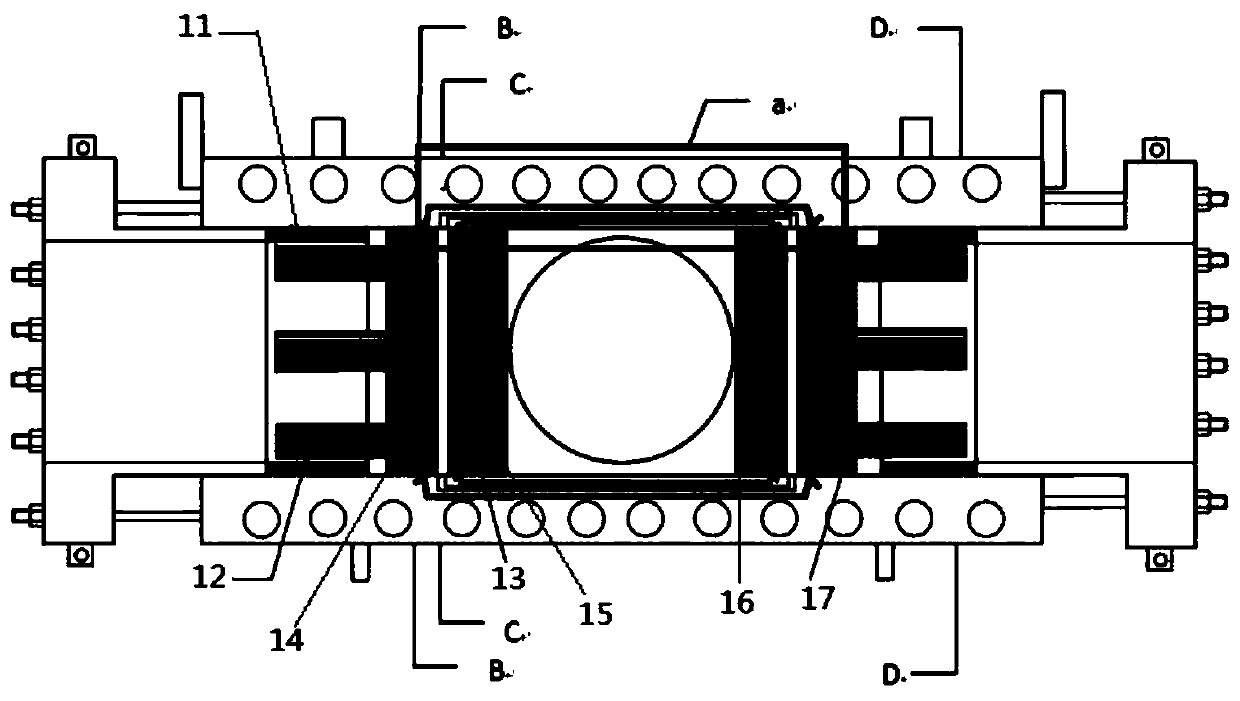

[0022] like Figures 1 to 9 As shown, a pressure-holding tee according to the present invention includes a tee body 6, a hydraulic cylinder 10, and lifting lugs 2. A row of transverse bolts 1 are respectively arranged on the top and bottom of the tee body 6, and the hydraulic cylinder 10 is installed through a hydraulic cylinder mounting column. 3 is connected with the tee body 6, and the hydraulic cylinder 10 can control the opening and closing of the tee body 6. The tee body 6 is provided with a positioning mechanism 28. The positioning mechanism 28 includes a push ring 11, a positioning slip 12 and a shear pin 29. The contact surface between the push ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com