Propellant combustion smoke concentration testing device

A technology of combustion smoke and testing equipment, which is applied in the direction of measuring equipment, gas turbine engine testing, jet engine testing, etc. It can solve problems such as laborious and laborious, poor response performance, pollution, etc., and achieve safety assurance, easy cleaning and maintenance, The effect of reducing processing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further explained by the following examples.

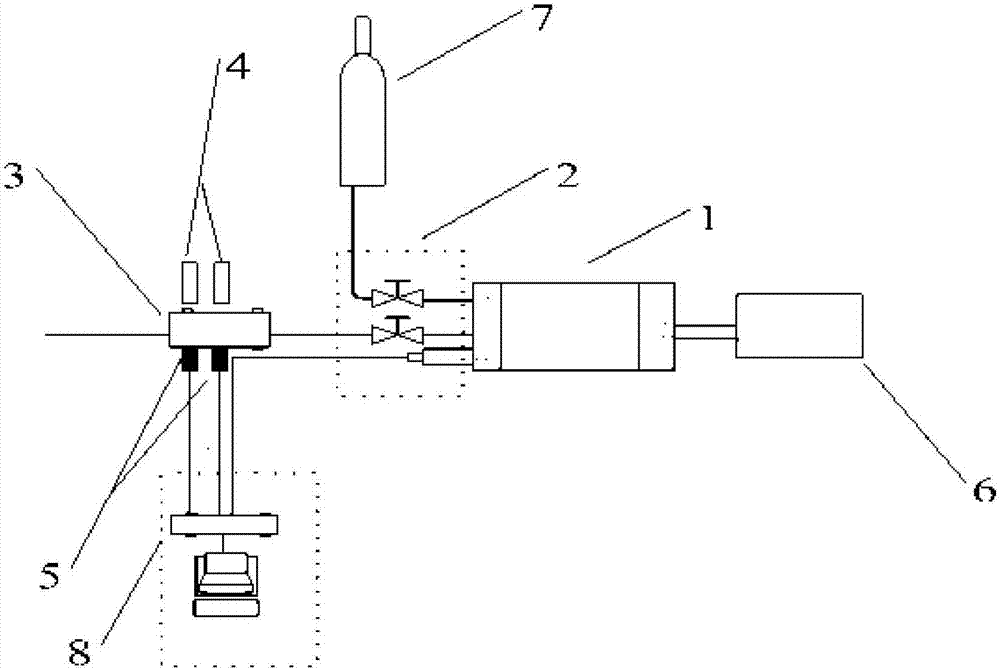

[0028] Such as figure 1 As shown, the propellant combustion smoke concentration test device is composed of a closed combustion chamber 1, a pressure regulation module 2, a test chamber 3, a light source 4, a light intensity detection sensor 5, an ignition power supply 6, a high-pressure gas source 7 and a data acquisition and processing module 8;

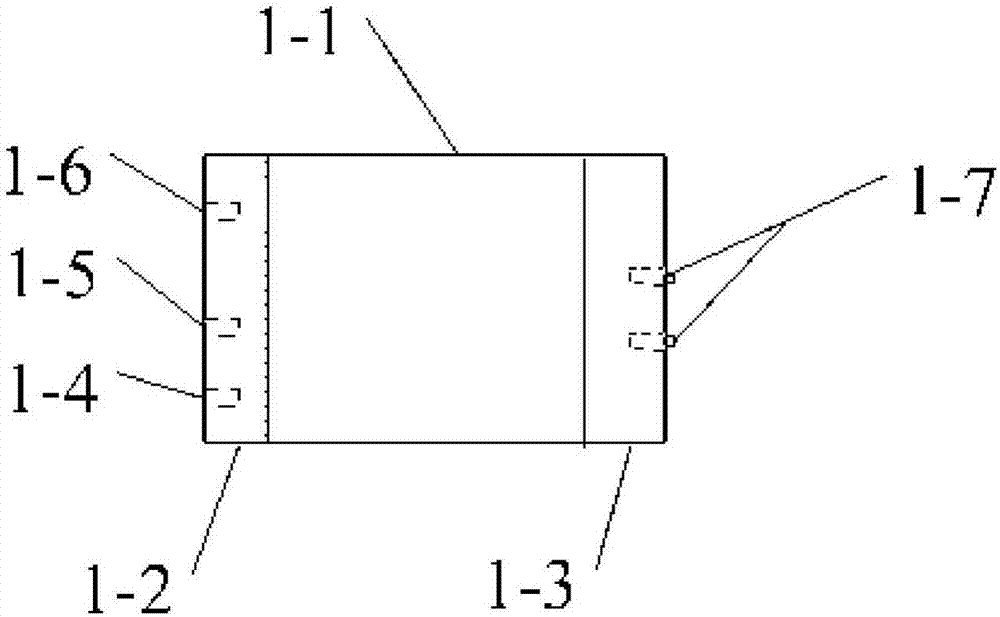

[0029] The function of the closed combustion chamber 1 is to provide a combustion environment with a certain initial pressure for the test sample; the function of the module pressure adjustment module 2 is to control the high-pressure gas source 7 to provide the initial pressure for the closed combustion chamber 1, and to control the closed combustion chamber 1 and the test chamber. 3 on and off; the light source 4 and the light intensity detection sensor 5 are respectively located on both sides of the glass window of the test chamber 3; the ignition...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com