Array substrate and its repairing method and liquid crystal display device

An array substrate and auxiliary electrode technology, applied in the field of array substrate and its repair method and liquid crystal display device, can solve the problems of poor image quality, limited increase in transmittance, flickering storage capacitor, etc., and achieve low power consumption and reduced The refresh rate and display effect are not affected

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

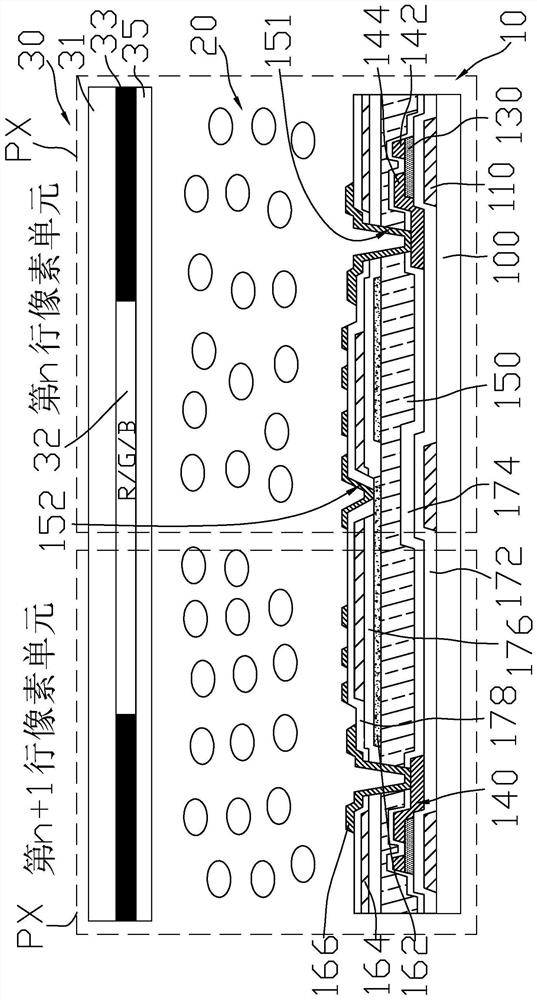

[0028] Such as figure 1 As shown, the liquid crystal display device of this embodiment includes an array substrate 10 , a liquid crystal layer 20 and a color filter substrate 30 , and the liquid crystal layer 20 is disposed between the array substrate 10 and the color filter substrate 30 .

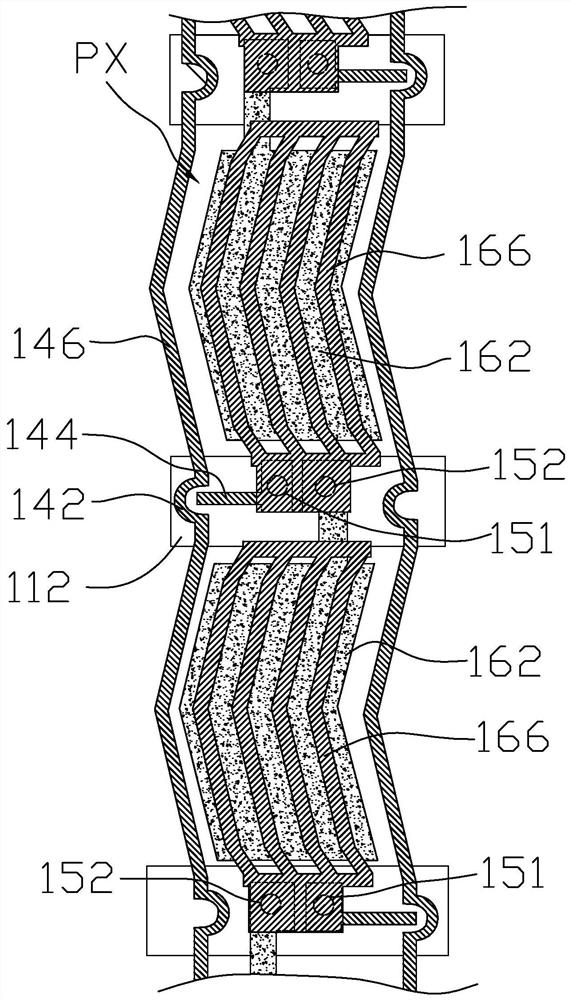

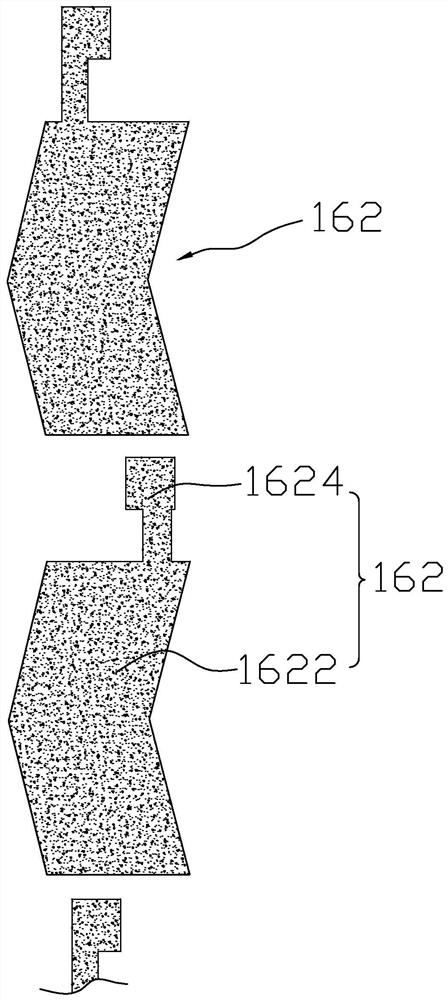

[0029] Such as figure 1 and figure 2 As shown, the array substrate 10 includes a gate layer 110 , a source-drain layer 140 , a plurality of auxiliary electrodes 162 , a common electrode 164 and a plurality of pixel electrodes 166 . The gate layer 110 and the source-drain layer 140 are insulated from each other. The plurality of auxiliary electrodes 162, the common electrode 164 and the plurality of pixel electrodes 166 are spaced apart from each other, wherein the plurality of auxiliary electrodes 162 are located below the plurality of pixel electrodes 166, and the common electrode 164 is located under the plurality of pixel electrodes 166. Between the auxiliary electrode 162 and the p...

no. 2 example

[0039] Such as Figure 5 As shown, the liquid crystal display device of this embodiment includes an array substrate 10 , a liquid crystal layer 20 and a color filter substrate 30 , and the liquid crystal layer 20 is disposed between the array substrate 10 and the color filter substrate 30 .

[0040] Such as Figure 5 and Figure 6 As shown, the structure of the array substrate 10 of this embodiment is the same as that of the above-mentioned first embodiment, the difference is that a method for repairing the array substrate 10 is also provided. In the array substrate 10 of this embodiment, the pixel electrode 166 in each pixel unit PX is conductively connected to the corresponding drain electrode 144 in the pixel unit PX through the first contact hole 151; in the upper and lower pixel units PX located in the same column, The pixel electrode 166 in the last pixel unit PX is conductively connected to the auxiliary electrode 162 in the next pixel unit PX through the second conta...

no. 3 example

[0043] Such as Figure 7 As shown, the liquid crystal display device of this embodiment includes an array substrate 10 , a liquid crystal layer 20 and a color filter substrate 30 , and the liquid crystal layer 20 is disposed between the array substrate 10 and the color filter substrate 30 .

[0044] Such as Figure 7 and Figure 8 As shown, the array substrate 10 includes a gate layer 110 , a source-drain layer 140 , a plurality of auxiliary electrodes 162 , a common electrode 164 and a plurality of pixel electrodes 166 . The gate layer 110 and the source-drain layer 140 are insulated from each other. The plurality of auxiliary electrodes 162, the common electrode 164 and the plurality of pixel electrodes 166 are spaced apart from each other, wherein the plurality of auxiliary electrodes 162 are located below the plurality of pixel electrodes 166, and the common electrode 164 is located under the plurality of pixel electrodes 166. Between the auxiliary electrode 162 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com