Electronic packaging material fake-prevention method and device

An electronic packaging material and packaging material technology, applied in the field of anti-counterfeiting, can solve the problems of inability to track and monitor, anti-counterfeiting technology is not real-time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0037] The embodiment of the present invention provides an anti-counterfeiting method for electronic packaging materials. The anti-counterfeiting method for electronic packaging materials is by adding a conductive layer 120 in the packaging material and adding a circuit easy-to-break point 121 in the conductive layer 120. When the packaging material is opened, the circuit The easy-to-break point 121 is disconnected to realize anti-counterfeiting.

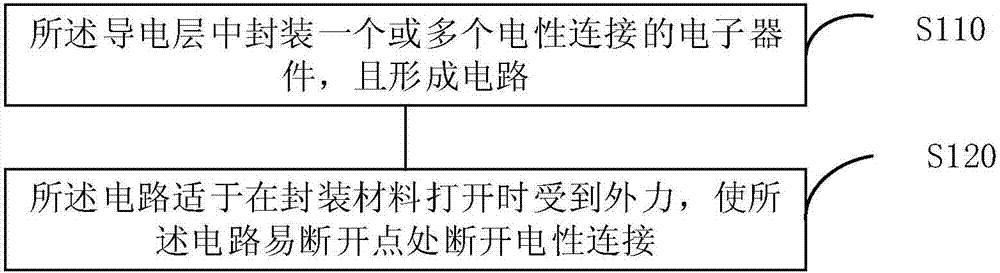

[0038] see figure 1 The steps of adding a conductive layer 120 to the packaging material to realize anti-counterfeiting include:

[0039] S110: Encapsulate one or more electrically connected electronic devices in the conductive layer, and form a circuit.

[0040] The conductive layer 120 encapsulates one or more electrically connected electronic devices. An electronic device, which can be, but is not limited to, an electrical wire, a resistor, a capacitor, an inductor, a diode, a transistor, a touch switch, a sensor electronic cir...

no. 2 example

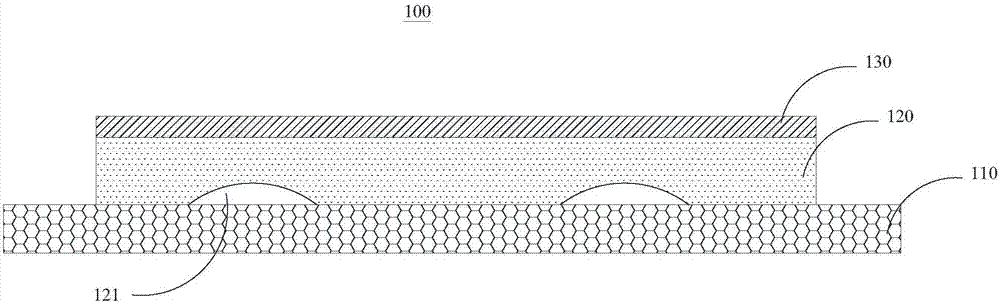

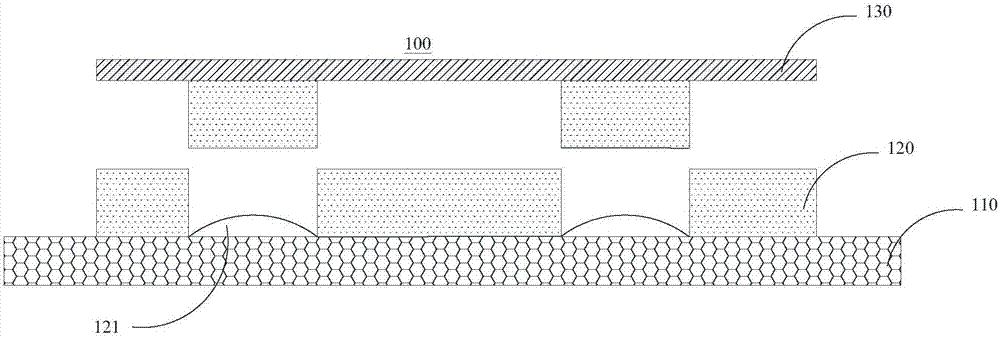

[0049] see figure 2 , the embodiment of the present invention provides an anti-counterfeiting device 100 . The anti-counterfeiting device 100 includes an encapsulation material with a conductive layer 120 inside; the conductive layer 120 includes at least one easily disconnected point 121;

[0050] The circuit easy-to-break point 121 is suitable for receiving an external force when the packaging material is opened, so as to change the circuit performance of the conductive layer 120 . The circuit break point 121 is suitable for changing the circuit performance of the conductive layer 120 when an external force is applied, so that the original packaging can be checked by electronic detection method.

[0051] Among them, the circuit easy-to-break point 121 can be, but not limited to, a single-layer circuit is disconnected, a multi-layer circuit is disconnected at the same point, a single-layer circuit is disconnected at different points, a multi-layer circuit is disconnected at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com