Glass cover plate, manufacturing method thereof and mobile phone

A technology of glass cover plate and manufacturing method, which is applied in the direction of telephone structure, printing, printing device, etc., and can solve problems such as unexperienced feeling, unsuitable cover plate for terminals, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

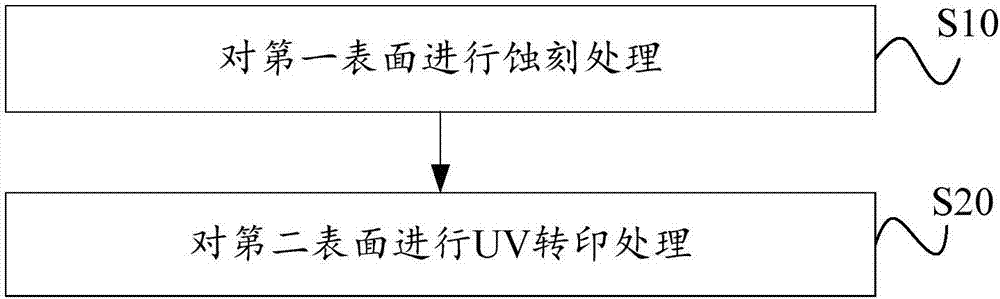

[0037] A method for manufacturing a glass cover. The mobile phone includes a body and a glass cover. The glass cover includes a first surface and a second surface oppositely arranged, wherein the second surface is arranged close to the body. The method for manufacturing the glass cover includes: The first surface treatment and the treatment of the second surface.

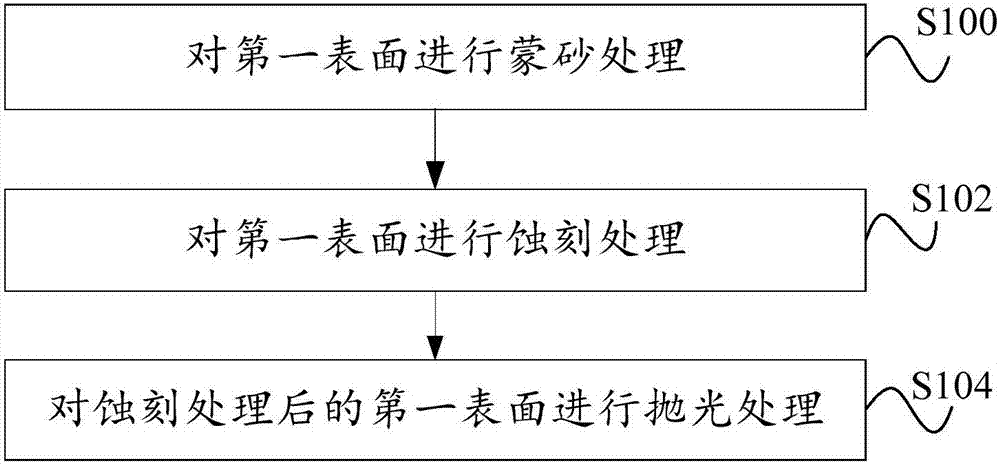

[0038] like figure 2 As shown, the treatment of the first surface includes:

[0039] Step S100, frosting the first surface. Use a solution made of glass frosting powder or other chemical raw materials to frost the glass surface to obtain a frosting effect and further improve the tactile and visual experience of the first surface.

[0040] Step S102, performing etching treatment on the first surface to obtain a desired pattern.

[0041] Preferably, step S102 specifically includes:

[0042] screen printing protective oil on the first surface;

[0043] Etching the first surface with protective oil on the silk scr...

Embodiment 2

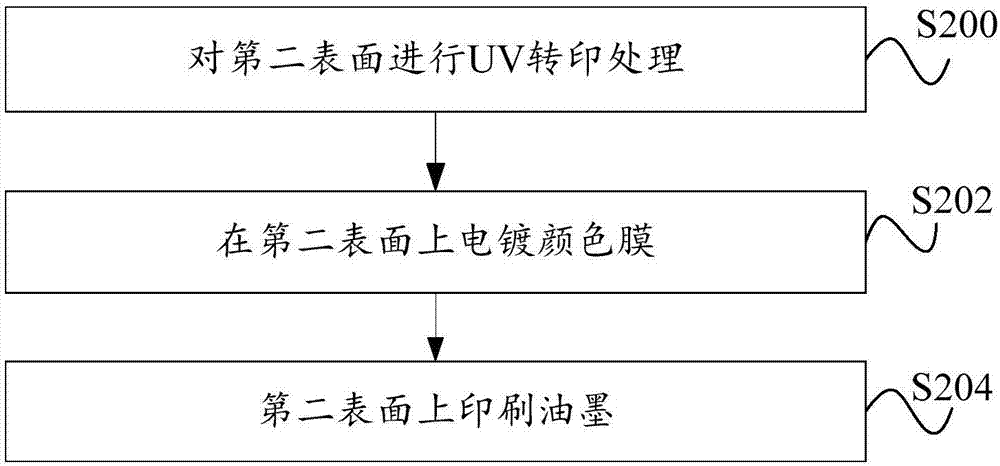

[0056] Such as Figure 4 As shown, step S204 in Embodiment 1 is replaced by step S204', step S204' is: after electroplating the color film, spray ink on the second surface, and the second surface can be colored or monochromatic according to the color of the ink. color effect.

Embodiment 3

[0058] The treatment method to the first surface is the same as in Example 1, and the treatment method to the second surface is: silk screen printing ink on the second surface, so that a single color or multiple colors can be obtained on the second surface, and the second surface presents flat effect.

[0059] The embodiment of the second aspect of the present invention provides a glass cover plate, which is made by the method for manufacturing the glass cover plate in any of the above-mentioned embodiments, and thus has all the beneficial effects of the method for manufacturing the glass cover plate in any of the above-mentioned embodiments , which will not be repeated here.

[0060] The embodiment of the third aspect of the present invention provides a mobile phone, including: a body and the glass cover of the above-mentioned embodiment, so it has all the beneficial effects of the glass cover of the above-mentioned embodiment, and will not be repeated here.

[0061] To sum ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com