Engine connecting rod small-end copper bush press-fitting device

A technology of engine connecting rods and press-fitting devices, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve problems such as low installation efficiency, achieve high installation accuracy, reduce labor intensity, and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following is a further detailed description through specific implementations:

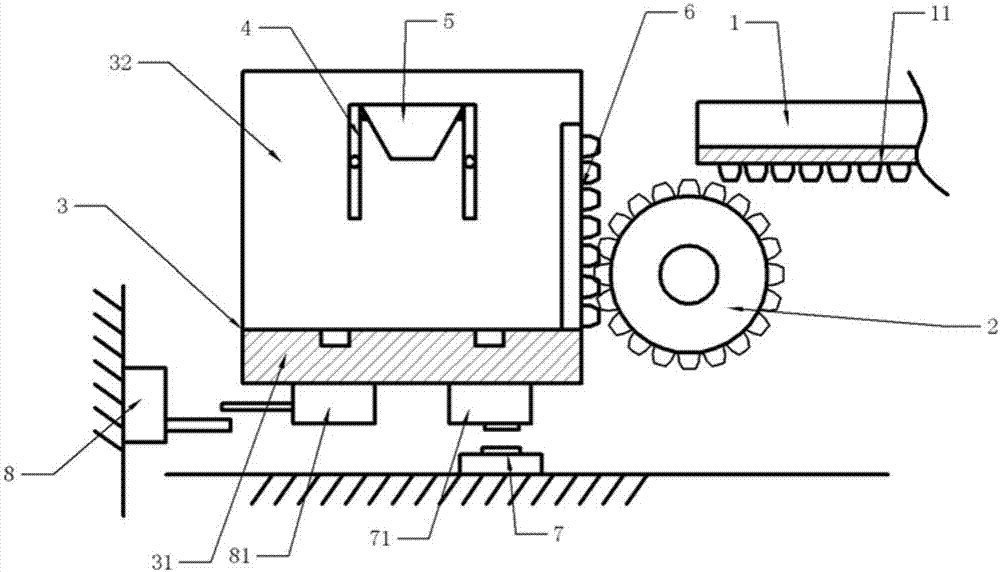

[0026] The reference signs in the drawings of the specification include: mounting block 1, first rack 11, gear 2, sliding plate 3, horizontal plate 31, limit slot 311, vertical plate 32, clamping rod 4, clamping block 5, The second rack 6, the first electromagnet 7, the first power supply 71, the second electromagnet 8, and the second power supply 81.

[0027] The embodiment is basically as attached figure 1 Shown:

[0028] The copper sleeve pressing device for the small end of the engine connecting rod includes a frame. The right end of the frame is slidably connected with a mounting block 1 along the horizontal direction. The mounting block 1 is provided with a first rack 11, and the mounting block 1 is provided with a fixing member , The fixing parts are fixing bolts. The left end of the frame is provided with a guide groove along the longitudinal direction, and the left end of the lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com