Sliding table saw

A technology for pushing table saws and saw wheels, which is applied to circular saws, sawing components, sawing equipment, etc., can solve the problems of time-consuming, laborious, and cumbersome collection of boards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

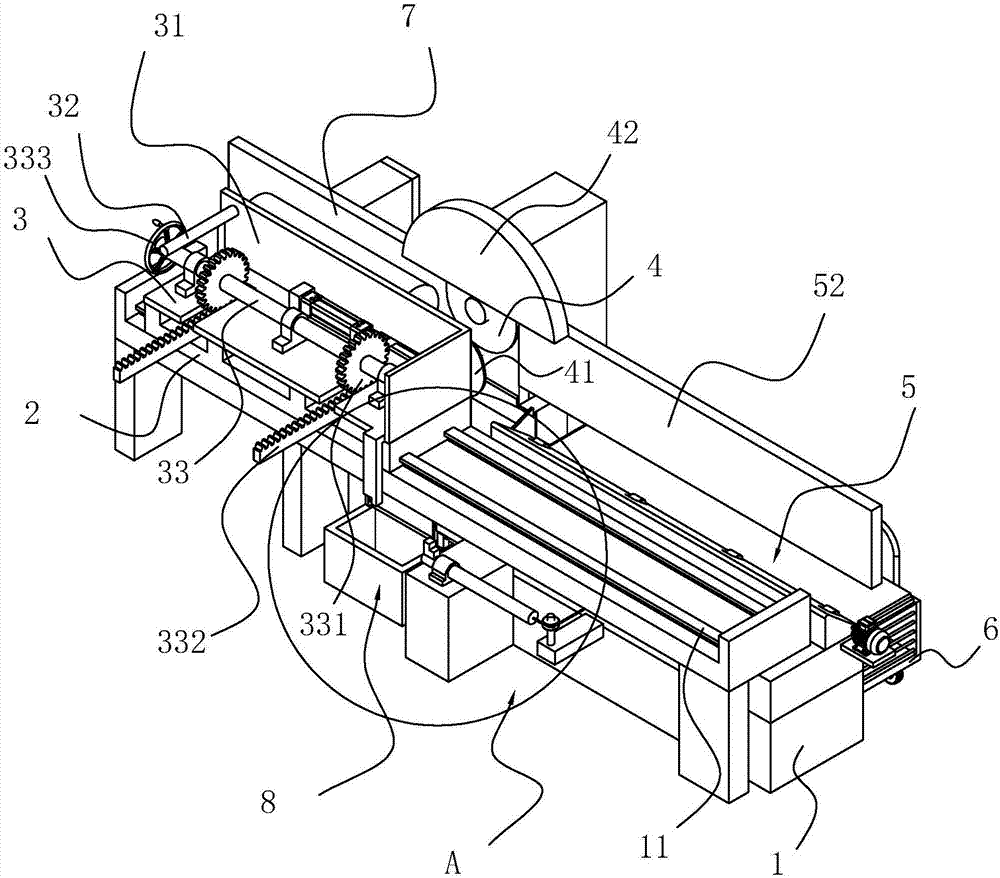

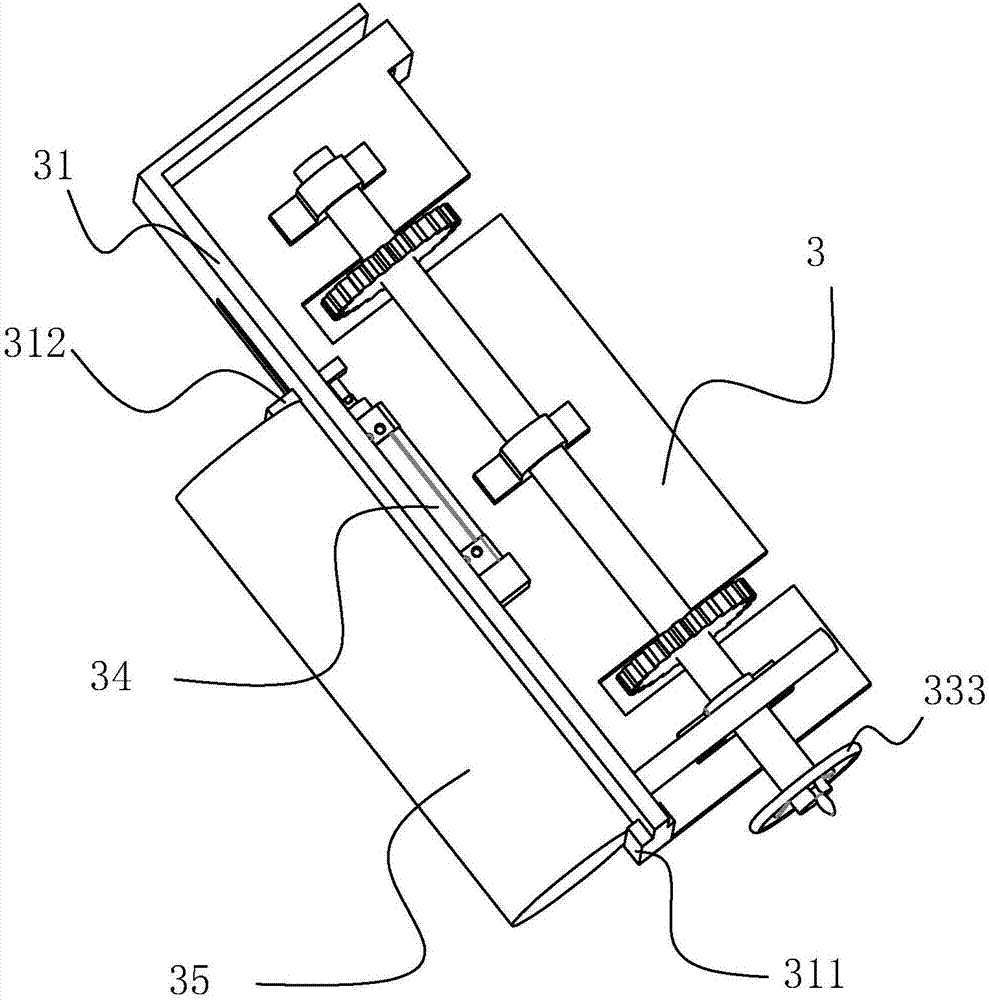

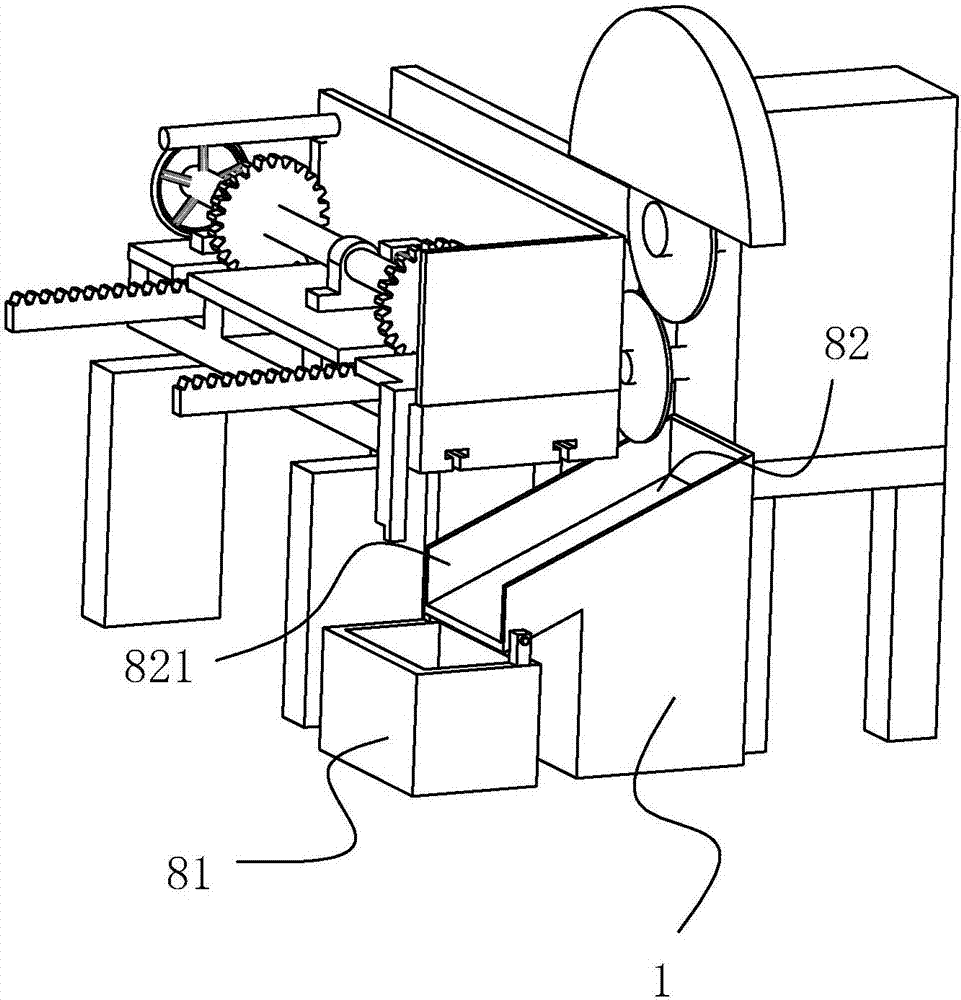

[0037] Embodiment: a kind of push table saw, see attached figure 1 , comprising a workbench 1, a slide table 2 that slides along the longer side of the workbench 1 on the workbench 1, a push-pull table 3 that can slide along the shorter side of the slide table 2, and a push-pull table 3 that is arranged on the workbench 1 The upper saw wheel 4 and the lower saw wheel 41 that are connected to the workbench 1 in rotation, the positioning plate 7 arranged on one side of the upper saw wheel 4 and the other side of the upper saw wheel 4 relative to the positioning plate 7 Unloading mechanism 5, upper saw wheel 4 is provided with cover on upper saw wheel 4 and prevents the protective cover 42 that staff contacts with saw wheel, is provided with sawdust collection mechanism 8 that sawdust is collected below saw wheel 41, will need to carry out The processed log 35 is clamped on the side of the push-pull table 3 close to the upper and lower saw wheels 41, and then the push-pull table ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com