Enamel processing process used for metal weaving

A processing technology and metal weaving technology, which is applied in the field of enamel, can solve the problems of inability to make large sculptures or jewelry, the loss of toughness of the metal carcass, and the unit volume weight of enamel. little effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

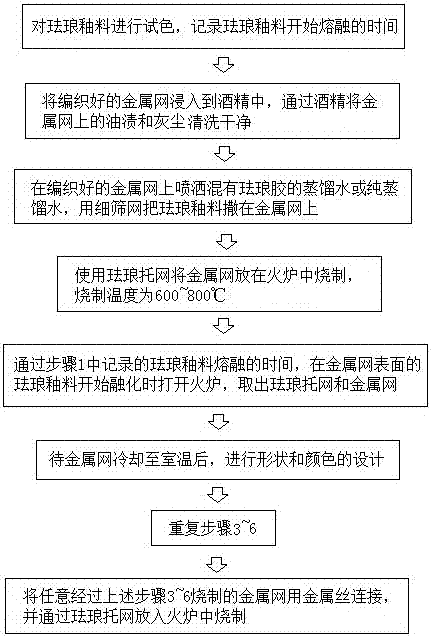

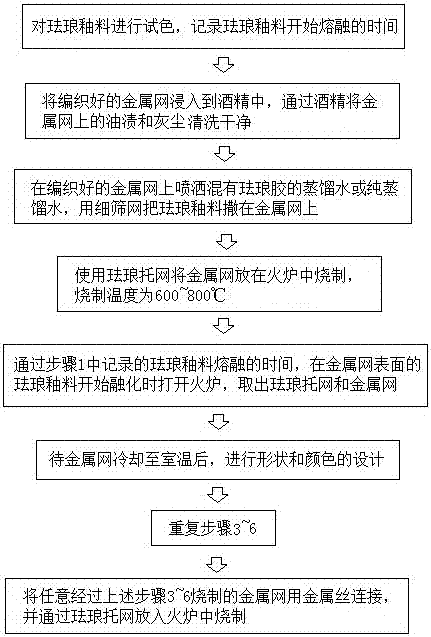

[0031] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0032] See figure 1 , a kind of enamel processing technique for metal weaving of the present invention, at least comprises the following steps:

[0033] Step 1: Test the color of the enamel glaze before firing, and record the time when the enamel glaze begins to soften and melt. Specifically include the following steps:

[0034] Step 1.1, label the enamel glazes of the colors to be used in turn, wash and apply on the prepared metal carcass, the thickness of the metal carcass should be the same as the thickness of the metal wire, then absorb the water, and put the metal carcass on the Dry over the stove or let it dry naturally;

[0035] Step 1.2, put the metal carcass for color test into the stove for the first firing, the first firing time is 45 seconds, take out the stove after 45 seconds. The normal firing time is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com