An auxiliary device for deploying and recovering shock absorption for an underwater robot

An underwater robot and auxiliary device technology, which is applied to springs/shock absorbers, underwater operation equipment, mechanical equipment, etc., can solve the problems affecting the deployment and recovery of underwater robots, collisions of underwater robots, and easy occurrence of collisions, etc. To achieve the effect of convenient hook, reduce bump and vibration, easy to disassemble

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

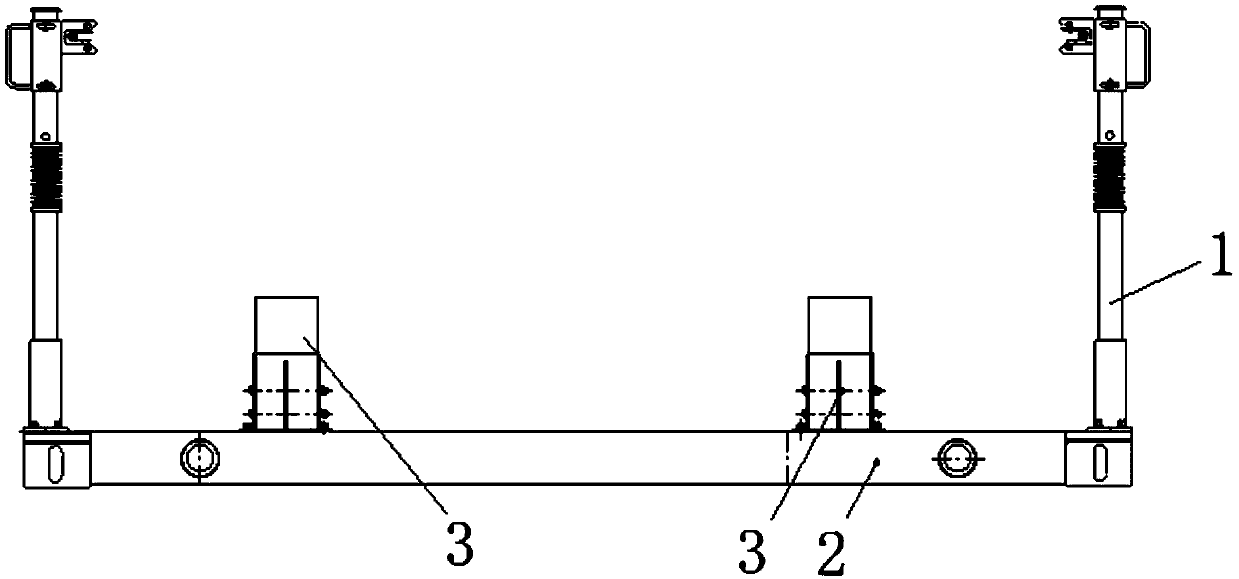

[0036] Such as Figure 5-6 As shown, the structure of the underwater robot 21 in this embodiment is a rotary type, and the buffer device 1 is fixed on the end of the transportation platform 2 .

[0037] The underwater robot 21 in this embodiment has a total weight of about 1.5t. The hydraulic damper of the model YZN32 produced by Changzhou Rongda Structural Damping Co., Ltd. is selected. The itinerary is optional.

[0038] The working principle of this embodiment is:

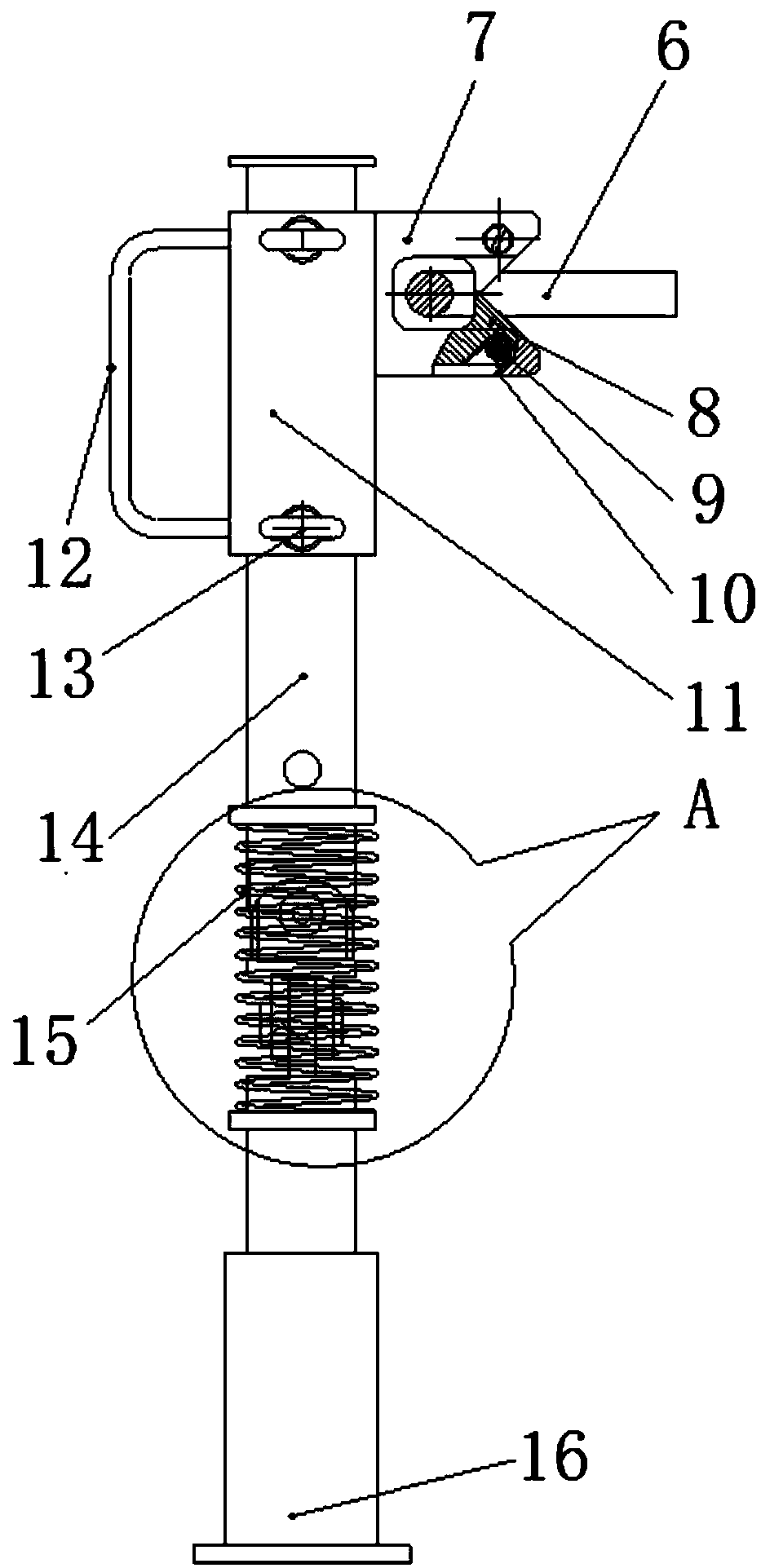

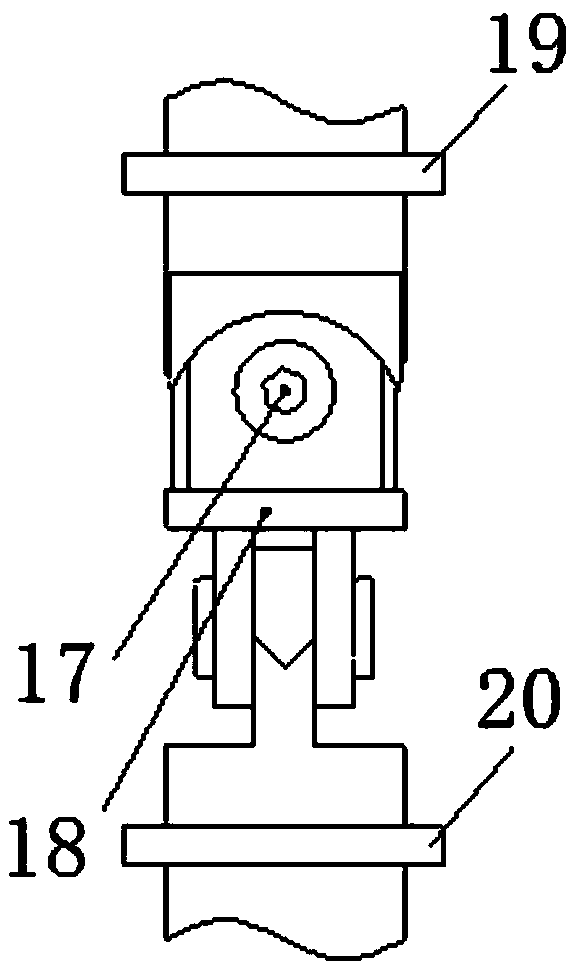

[0039] When the underwater robot 21 is hoisted from the water surface to the hull through the lifting hook 5 and the lifting rope 4, two operators at the bow and stern complete the locking of the bow and stern rings 6 of the underwater robot and the anti-disengagement locks 7 on the front and rear buffer devices 1. When the hook works, the horizontal and vertical shaking of the underwater robot 21 is basically very little at this time, and the anti-swing rope can be removed, and the operator operates the crane...

Embodiment 2

[0042] Such as Figure 7-9 As shown, the underwater robot 21 in this embodiment is a non-revolving type, and the buffer device 1 is hinged to the end of the transportation platform 2, and the others are the same as in the first embodiment.

[0043] The working principle of this embodiment is:

[0044] After the underwater robot 21 is hoisted from the water surface to the hull by the lifting hook 5 and the lifting rope 4, the buffer devices 1 at both ends of the transport platform 2 are first in an open state, and then the underwater robot 21 is dropped into between the two buffer devices 1, And hook with the anti-off lock 7 on the front and rear end buffer devices 1, remove the anti-swing rope, the operator operates the crane to slowly sit down, the sliding connecting pipe 11 and the slide rail pipe 14 slide relative to each other during the falling process, and fall to the lowest end, the crane continues When it is lowered, the hydraulic damping cylinder 16 starts to work, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com