Hanging-type conveying rack for tunnel bricks

A transport frame and hoisting technology, applied in the field of tunnel brick production and processing, can solve the problems of the ground space occupied by the conveyor belt, the limited layout of the conveyor belt, and the large land occupied by the production of tunnel bricks, etc., so as to improve the utilization rate of the site and reduce the transportation cost. The effect of long process time and convenient linear layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

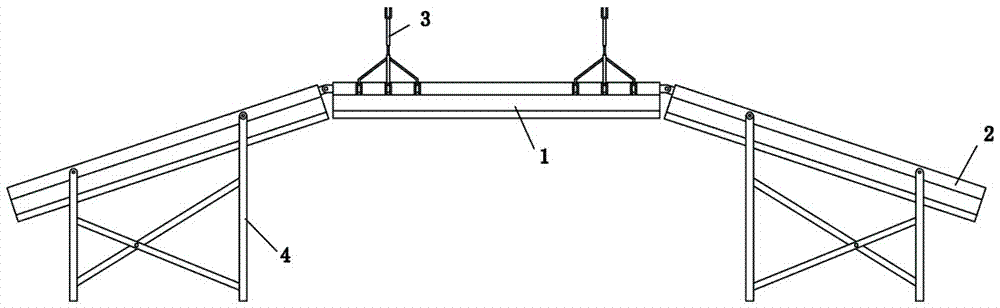

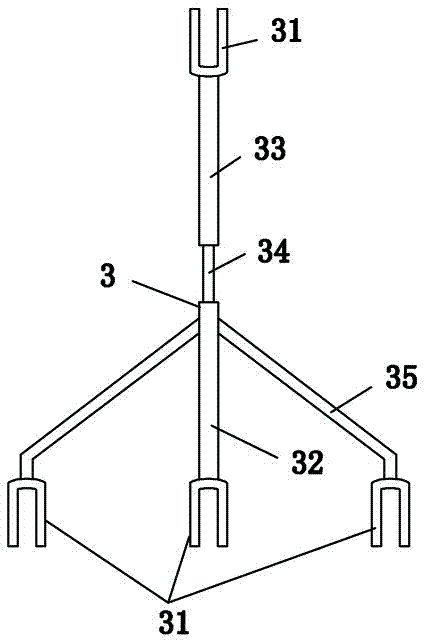

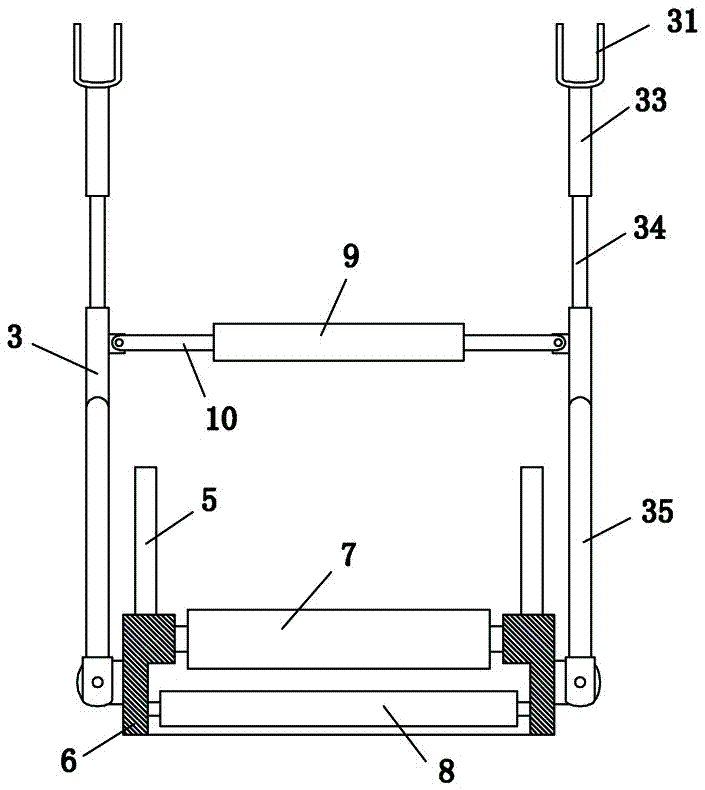

[0018] Such as Figure 1-5 As shown, a hanging transport frame for tunnel bricks includes an overhead support 1 and a slope support 2. The hanging lug is provided with a support boom 3 through a pin, and the overhead support 1 is suspended on the beam or purlin of the factory building through the support boom 3. The two sides of the slope support 2 are fixed on the ground through the stand 4, and the overhead support 1 and The slope support 2 is composed of two angle steel beams 6 with the same structure facing in parallel, and a plurality of parallel rollers 7 and supporting rotating rods 8 are arranged between the two angle steel beams 6, and the two rollers 7 and supporting rotating rods 8 The end is connected on the angle steel crossbeam 6 through bearings, and the supporting rotating rod 8 is positioned at the bottom of the drum 7, the angle steel crossbeam 6 is vertically fixedly provided with a retaining plate 5, and the drum 7 and the supporting rotating rod 8 are prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com