A kind of fine denier snow lotus microcapsule cellulose fiber and its preparation method

A cellulose fiber and microcapsule technology, which is applied in the directions of microcapsule preparation, microsphere preparation, cellulose/protein conjugated artificial filament, etc. Cellulose fibers, insufficient softness and comfort, etc., to achieve the effects of low preparation fineness, improved embedding rate and sphericity, and good skin care

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

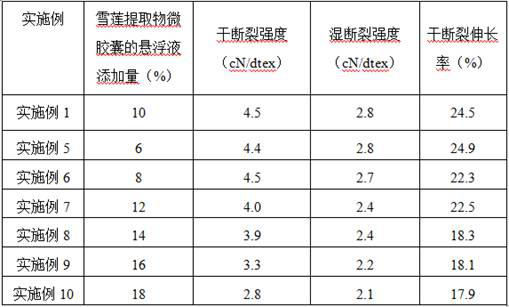

Embodiment 1

[0058] Embodiment 1 A kind of preparation method of fine denier snow lotus microcapsule cellulose fiber,

[0059] Include the following steps:

[0060] (1) Preparation of snow lotus extract emulsified dispersion

[0061] The content of the active ingredient is 18% peach gum solution, 10 parts of the purchased snow lotus extract and 15 parts of the peach gum solution are mixed, heated to 65 ° C, stirred and emulsified, and the stirring speed is 200 r / min, so that the snow lotus extract is emulsified Disperse, after being completely dissolved, filter, and remove insoluble impurities to obtain snow lotus extract emulsified dispersion;

[0062] Snow lotus extract, brown powder, 100% passed through 80 mesh sieve, ash content≤3.2%, moisture content≤3.8%, heavy metal content≤5ppm, lead content≤1ppm, arsenic content≤0.5 ppm, mercury content≤0.4 ppm, total bacteria ≤500cfu / g, the total number of molds ≤50 cfu / g, Salmonella and Escherichia coli shall not be detected.

[0063] (2) Pre...

Embodiment 2

[0083] Embodiment 2 A kind of preparation method of fine denier snow lotus microcapsule cellulose fiber,

[0084] Include the following steps:

[0085] (1) Preparation of snow lotus extract emulsified dispersion

[0086] Calculate the parts by weight of the snow lotus extract and the peach gum solution, mix 8 parts of the snow lotus extract and 17 parts of the peach gum solution, heat to 65 ° C after mixing, stir and emulsify, and the stirring speed is 220r / min, so that the snow lotus extract is emulsified and dispersed, After being completely dissolved, the insoluble impurities are removed by filtration to obtain a snow lotus extract emulsified dispersion;

[0087] The snow lotus extract is produced by Xi'an Virgin Biotechnology Co., Ltd. and is commercially available;

[0088] The peach gum solution is prepared by dissolving peach gum in water; the content of the active ingredient of peach gum in the peach gum solution is 18%;

[0089] The snow lotus extract, brown powder...

Embodiment 3

[0113] Embodiment 3 A kind of preparation method of fine denier snow lotus microcapsule cellulose fiber,

[0114] Include the following steps:

[0115] (1) Preparation of snow lotus extract emulsified dispersion

[0116] Calculate the parts by weight of the snow lotus extract and the peach gum solution, mix 8 parts of the snow lotus extract and 158 parts of the peach gum solution, heat to 870 ° C, stir and emulsify, and the stirring speed is 200r / min, so that the snow lotus extract is emulsified and dispersed, After being completely dissolved, the insoluble impurities are removed by filtration to obtain a snow lotus extract emulsified dispersion; the snow lotus extract is produced by Xi'an Virgin Biotechnology Co., Ltd. and is commercially available; the peach gum solution is prepared by dissolving peach gum in water. ; The content of the active ingredient of peach gum in the peach gum solution is 18-20%;

[0117] The snow lotus extract, brown powder, 100% passed through 80 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| breaking strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com