Roller for fixation of dredging cable of pipeline slit remover, and matched fixing method for dredging cable

The technology of a dredging machine and a drum is applied in the field of pipeline dredging and cleaning equipment, which can solve the problems of low equipment efficiency and high energy consumption, and achieve the effects of prolonging the service life, reducing wear and reducing noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

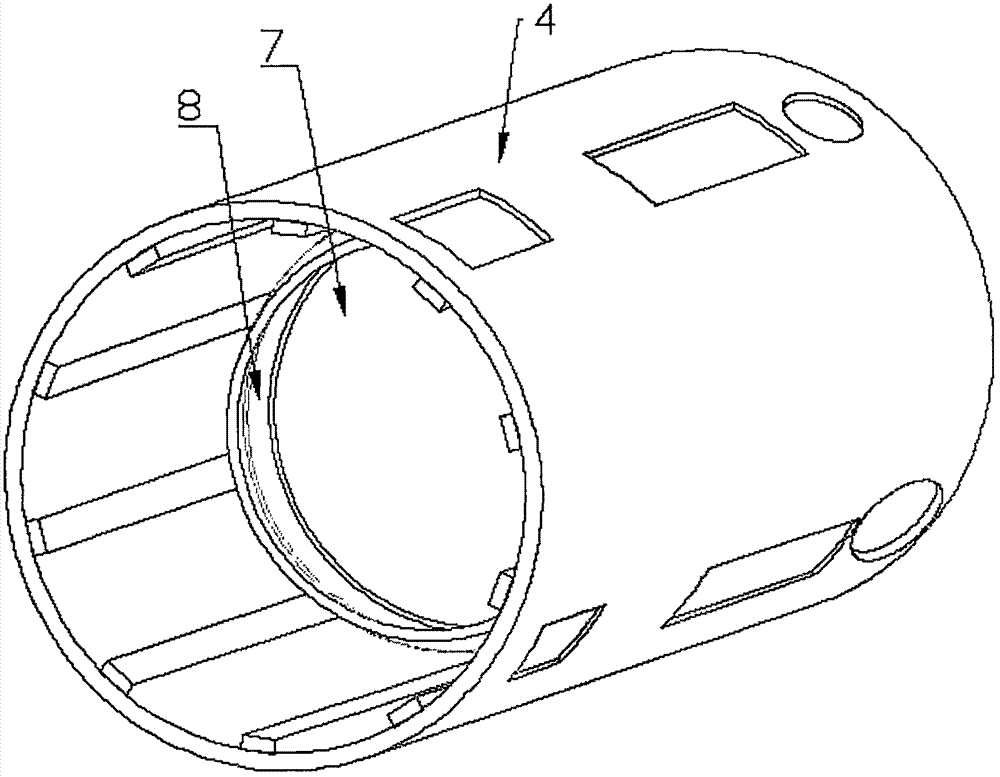

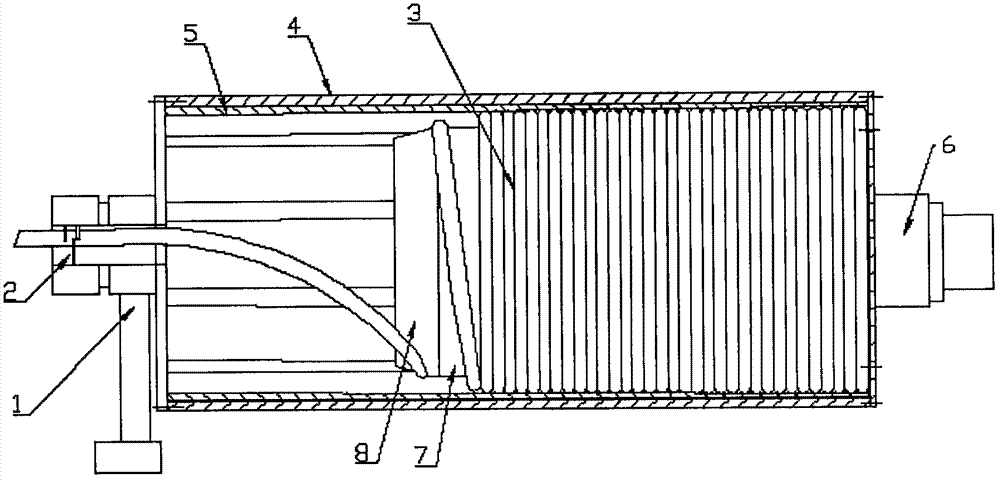

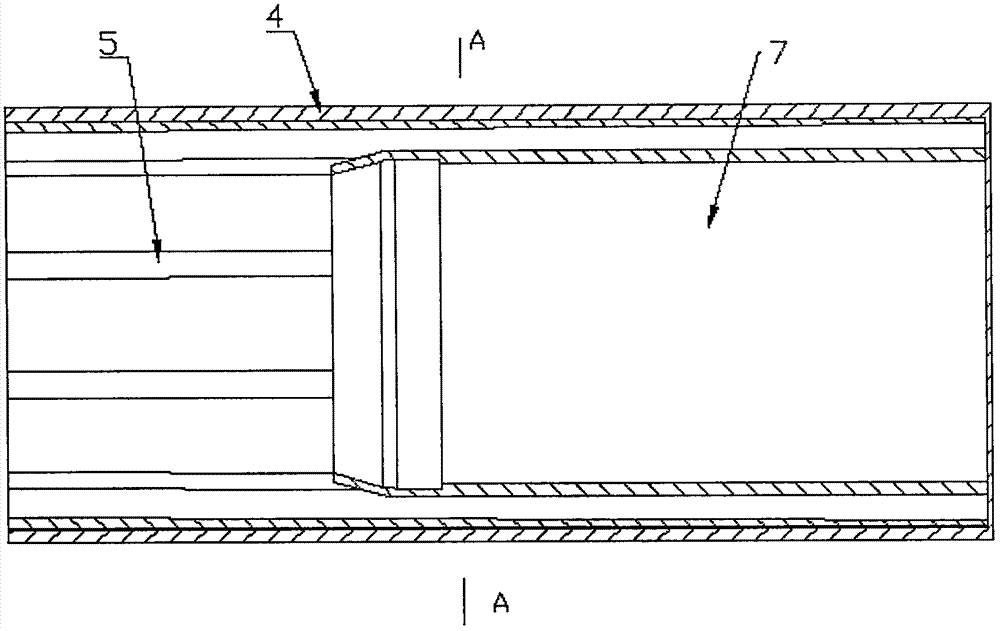

[0028] Such as Figure 1-4 As shown, the present invention provides a drum for fixing the dredging cable in a pipeline dredging machine, comprising an outer layer storage tube 4 and an inner layer sleeve 7 installed coaxially; The blue cover, wherein, the outer surface of the right end flange cover is successively installed with the right end concentric shaft and the drum power source that drives the right end concentric shaft to rotate, and the middle part of the left end flange cover is provided with a hollow shaft communicating with the inner cavity of the drum, and a circlip 1 is fitted on the hollow shaft via a bearing, and the spring device 1, which limits the degree of freedom of the flexible shaft on the vertical plane, is connected to the clamping power source; the flexible shaft storage cavity is formed between the outer storage tube 4 and the inner sleeve 7, so that The flexible shaft can be wound in the outer storage tube 4 circle by circle in the cavity until it p...

Embodiment 2

[0039] The principle of this embodiment is the same as that of Embodiment 1, the specific difference is that the guide tube 8 is clamped on the inner sleeve 7 . Make the transition surface smoother, and further improve the guiding effect on the soft axis. In this embodiment, the hydraulic motor of the circlip device 1 is replaced by a conventional belt drive.

[0040] In addition, if Figure 5 As shown, the width of the limiting plate corresponds to a central angle of 36 degrees. In actual working conditions, the width of the limiting plate roughly corresponds to the width of the gap. On the one hand, it ensures the realization of the limit, and on the other hand, it saves materials. Reduce friction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com