High-precision ignition system

An ignition system, high-precision technology, applied in electrical automatic control, automatic control, automatic control and other directions, can solve problems such as large fluctuations in rotation speed, large ignition timing deviation, engine recoil, etc., to achieve high-precision design, control accuracy ± 1° effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to enable those skilled in the art to better understand the solutions of the present invention, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

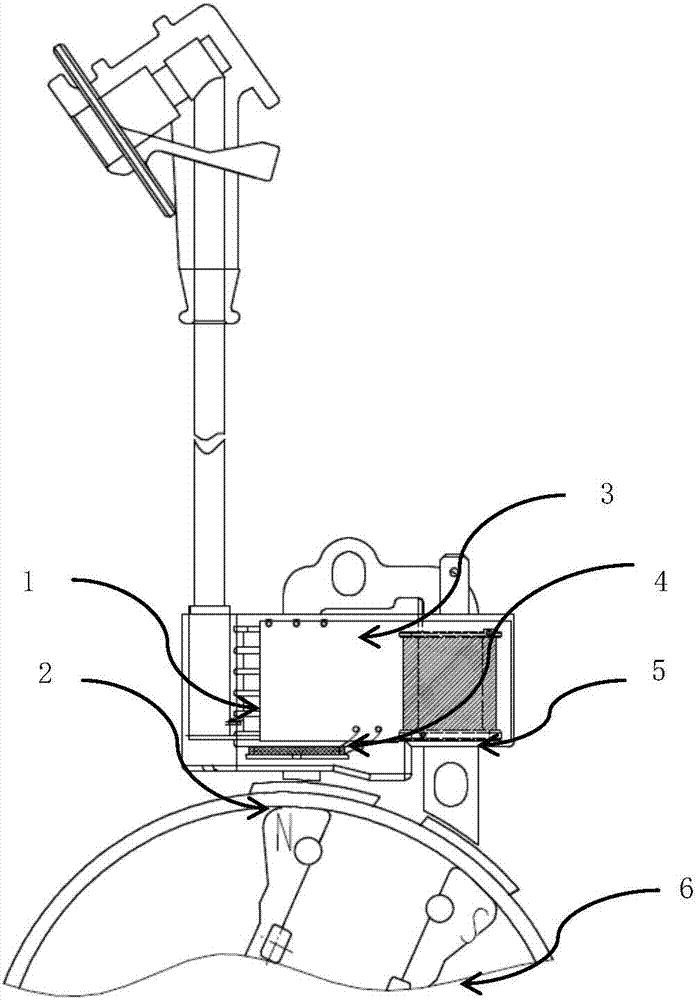

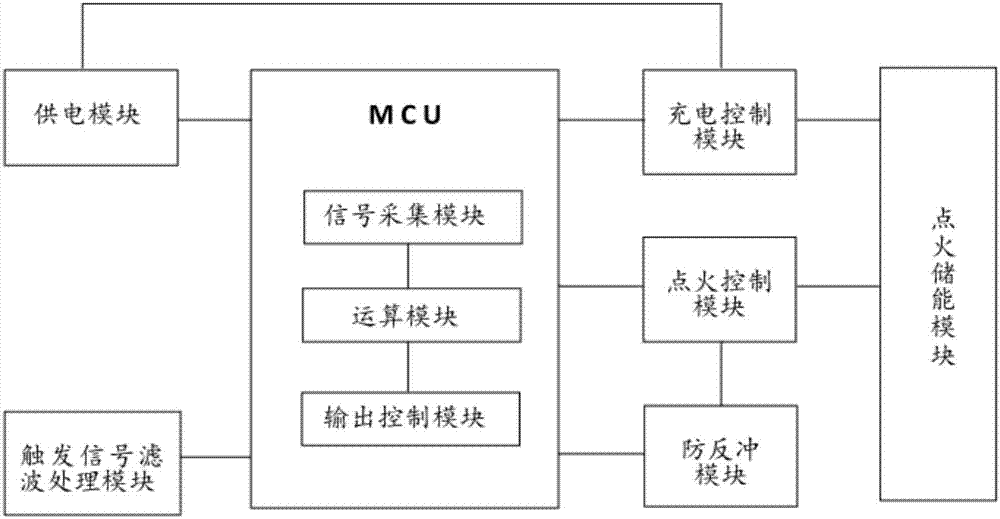

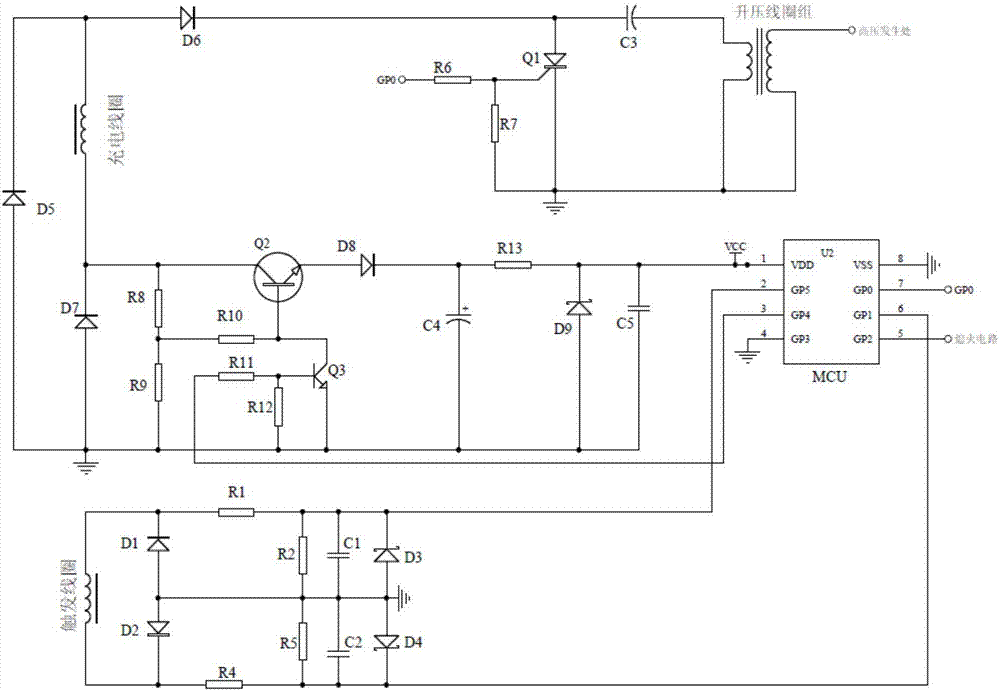

[0024] Such as figure 1 As shown, a high-precision ignition system, its external mechanical structure includes booster coil group 1, trigger coil 2, iron core 3, MCU control system 4, charging coil 5, magnetic flywheel 6 and other general components of the igniter. The ignition system uses MCU as the control core to provide ignition signals for the operation of the engine; when the magnetic flywheel rotates counterclockwise, the induced voltage waveform is generated on the charging coil and the trigger coil through the change of the magnetic field, and the induced voltage waveform on the coil is The phase of the flywheel corresponds to the position of the actual magnetic pole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com