Sputtering film forming method, electronic device manufacturing method, and sputtering system

A technology for sputtering thin films and sputtering systems, which is applied in the fields of semiconductor/solid-state device manufacturing, electrical components, semiconductor/solid-state device testing/measurement, etc. Design and control, improve efficiency, increase the effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

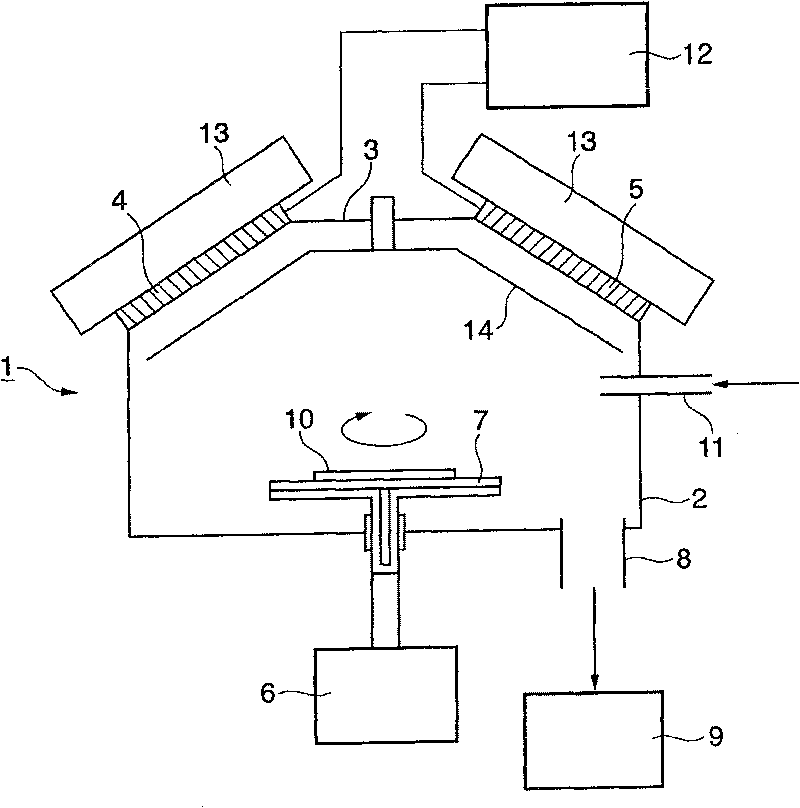

[0046] Figure 4 The sputtering system depicted in is used to form a single-layer hafnium film.

[0047] As the substrate 10, A silicon (Si) wafer is placed on the substrate holder 7, and the atmospheric pressure of the vacuum container 2 is reduced to 0.02 Pa. The baffle mechanism 14 is used to select a hafnium target, argon (Ar) gas is supplied as a discharge gas to the vacuum vessel 2 at 44.6 mg / min, and sputtering is performed.

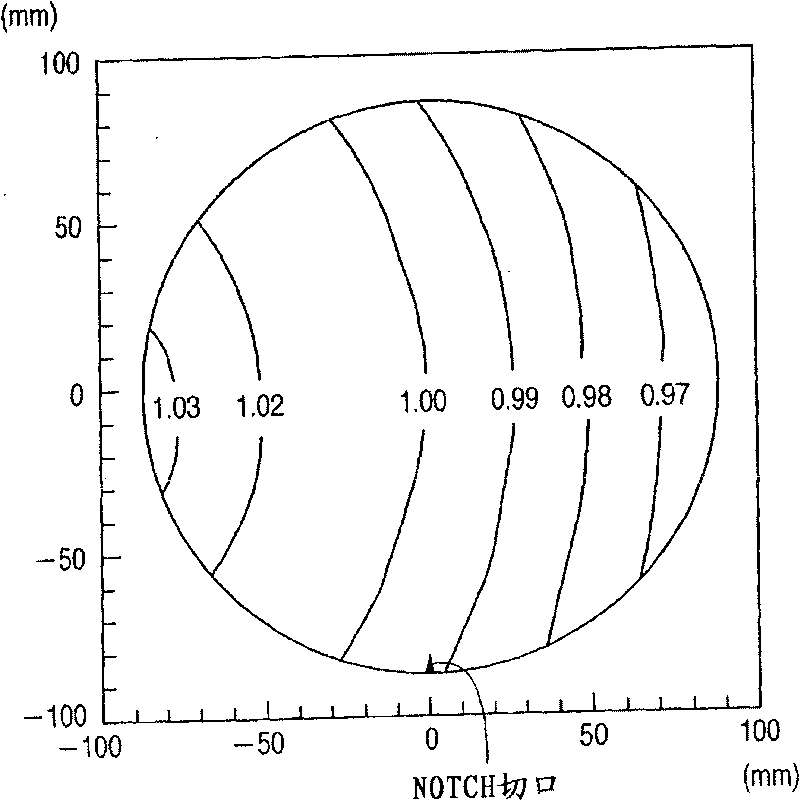

[0048] In this case, a cut is made in the edge portion of the wafer as the sputtering start point, and the sputtering starts when the cut passes a predetermined position as the start point, and when the cut passes, rotates from the start point in the circumferential track direction Sputtering stops at the half-turn position. The rotation speed of the wafer is 2 rpm. Assuming that the power applied to the target is 100 watts, so that the thickness of the hafnium film at the center of the substrate 10 will be 10 nm.

[0049] The thickness distribution ...

no. 2 approach

[0051] Figure 4 The sputtering system depicted in is used to form a stacked film of hafnium and tantalum films.

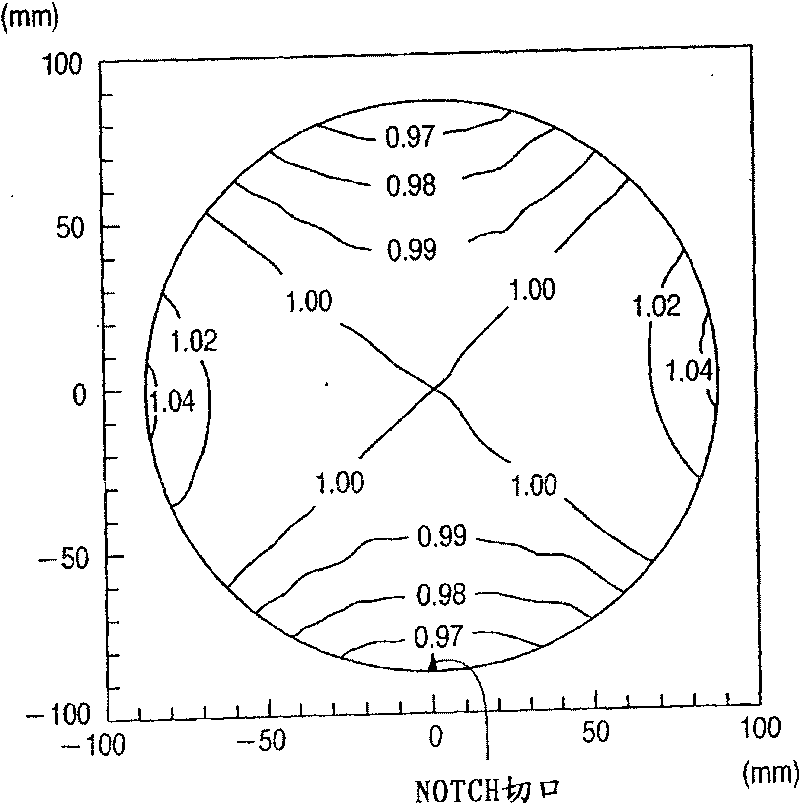

[0052] In order to deposit the thickest area of the tantalum film on the thinnest area of the hafnium film formed according to the first embodiment, establish the position of the notch on the wafer, use the baffle mechanism 14 to select the tantalum target, and the argon (Ar) gas at 44.6 mg / Provided separately, and perform sputtering. Assuming that the power applied to the target is 100 watts, so that the thickness of the tantalum film will be 10 nm at the center of the substrate 10. Thus, a laminated film in which a tantalum film is laminated on a hafnium film is obtained.

[0053] The thickness distribution of the laminated film thus obtained was measured using an ellipsometer, and the results are shown in Image 6 Portrayed in. Although the hafnium film and the tantalum film are laminated in such a manner that the film thickness is inclined by a given value, ...

no. 3 approach

[0058] The following is a description of electronic devices applicable to the present invention with reference to the accompanying drawings.

[0059] Figure 7 It is a flowchart depicting the electronic device manufacturing method according to the third embodiment. Figure 8 It is a conceptual configuration diagram depicting the MOS transistor 77 used according to the third embodiment. Picture 9 It is a conceptual configuration diagram of the MOS transistor 77 used in each respective manufacturing process according to the third embodiment.

[0060] In order to make Figure 8 The contact resistance between the gate electrode 73 of the MOS transistor depicted in and the wire 71 to the gate electrode is minimized, and it is necessary to install a compound 75 of nickel, platinum, and silicon (hereinafter referred to as "nickel platinum film 75"). Assuming that regarding the double-layer film of nickel and platinum formed on the MOS transistor 77, that is, the nickel-platinum film 72, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com