Sock packing machine

A technology for packaging machines and socks, which is applied in the direction of packaging, etc., can solve the problems of insufficient compactness and complexity of the device, and the slow supply speed of hooks, etc., and achieve the effects of improving the guiding function, facilitating installation and debugging, and facilitating control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

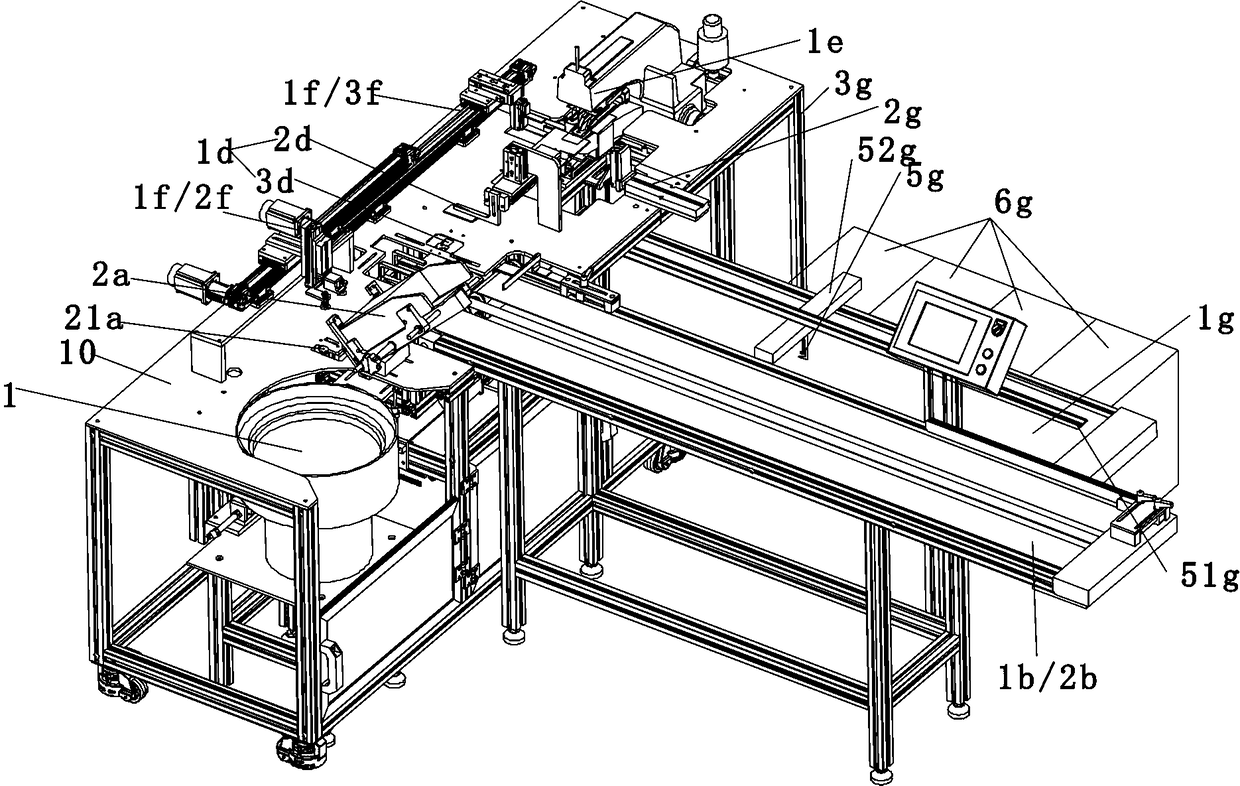

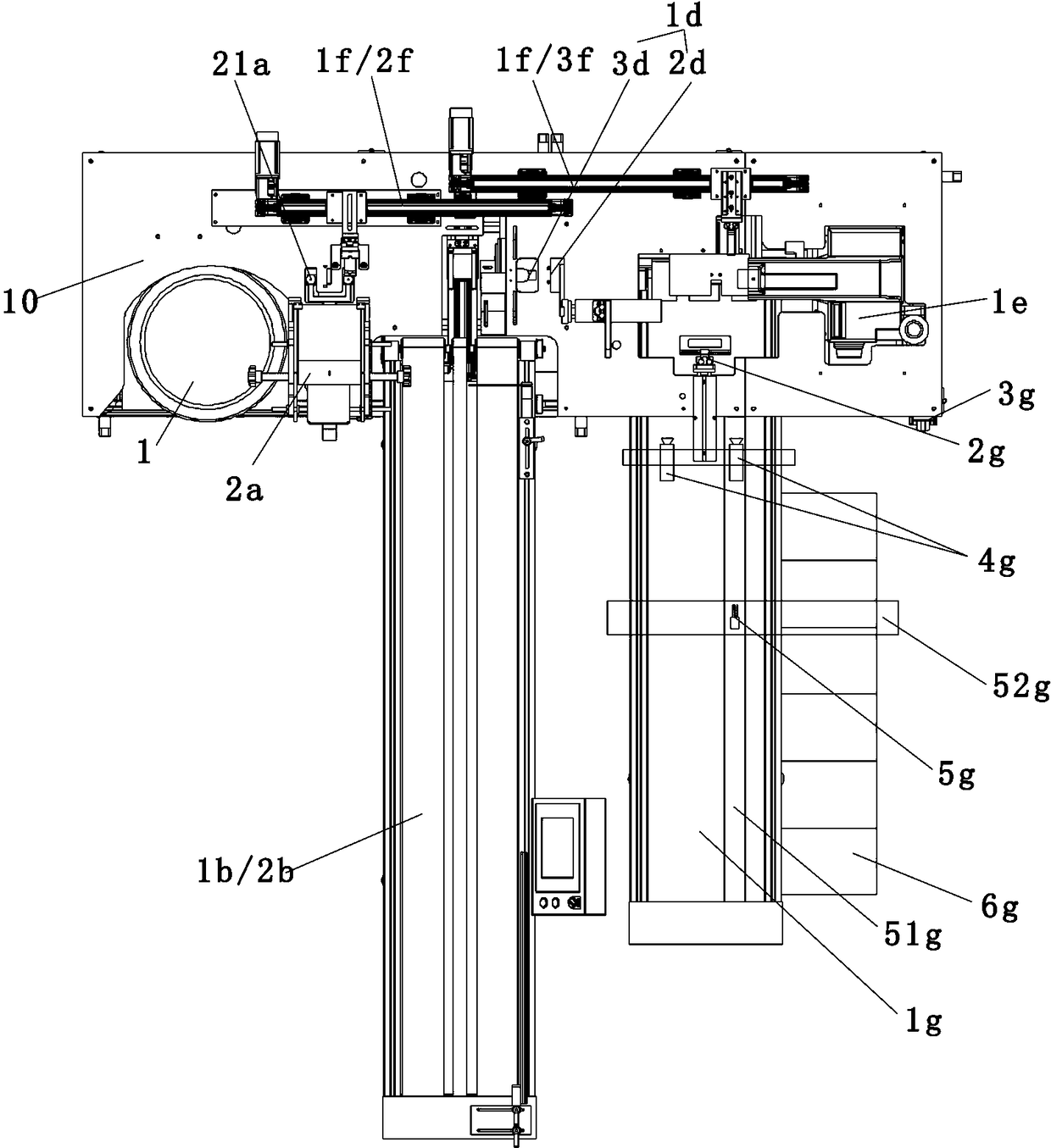

[0032] see Figure 1-4 , this implementation case includes a hook conveying mechanism, a card conveying mechanism 2a, a sock conveying mechanism 1b, a card bending mechanism 1d, a calibration mechanism 1e, a sock output mechanism 1g, a transfer mechanism 1f for transferring a workpiece transfer station, and a functional device connected to each part. The worktable 10 of the corresponding work station, the frame 3g of each component of installation and positioning.

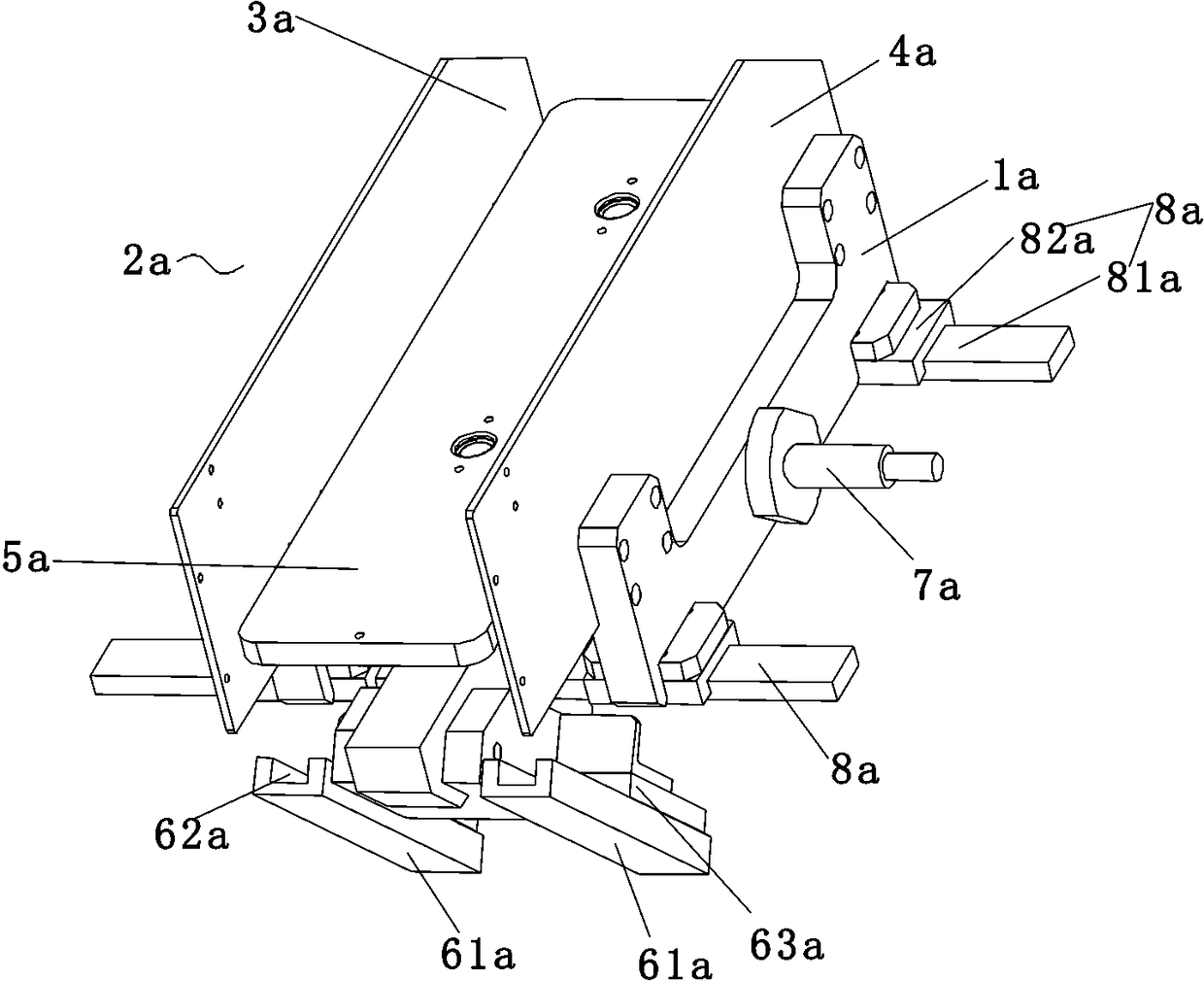

[0033] See Figure 6-8 The hook delivery mechanism includes a vibrating plate 1 for supplying hooks, a guide rod 2, and a delivery structure 3. The delivery structure 3 includes a base plate 31, a guide groove 32 arranged on the base plate 31, a push plate 33 sliding in the guide groove 32, The second driver 34 that drives the push plate 33 to slide; the guide rod 2 includes a suspension rod 21 that is suspended above the guide groove 32 and is located on the push path of the push plate 33, and is arranged at the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com