Density detecting robot system and detecting method thereof

A robot system and robot technology, applied in the field of intelligent robots, can solve problems such as the difficulty in realizing the density detection of hazardous chemicals, and achieve the effects of avoiding fluctuations, improving flexibility, and improving detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

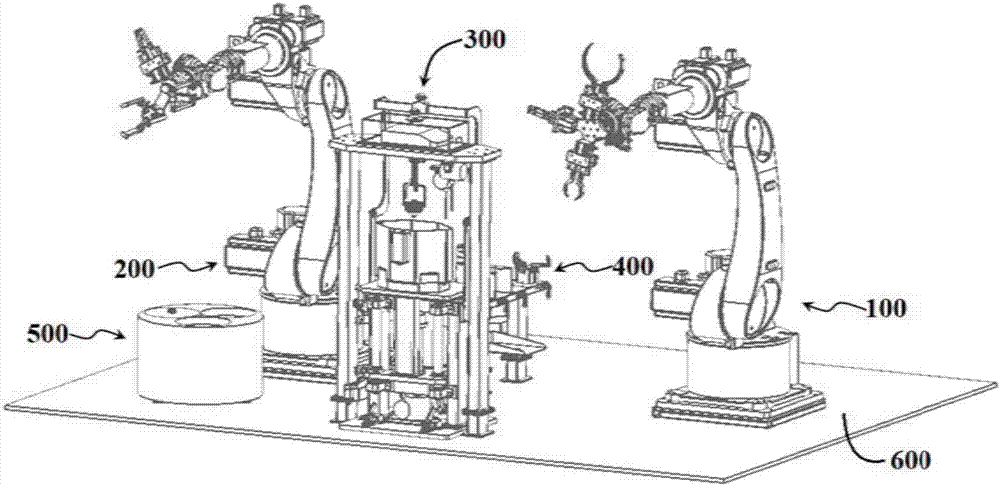

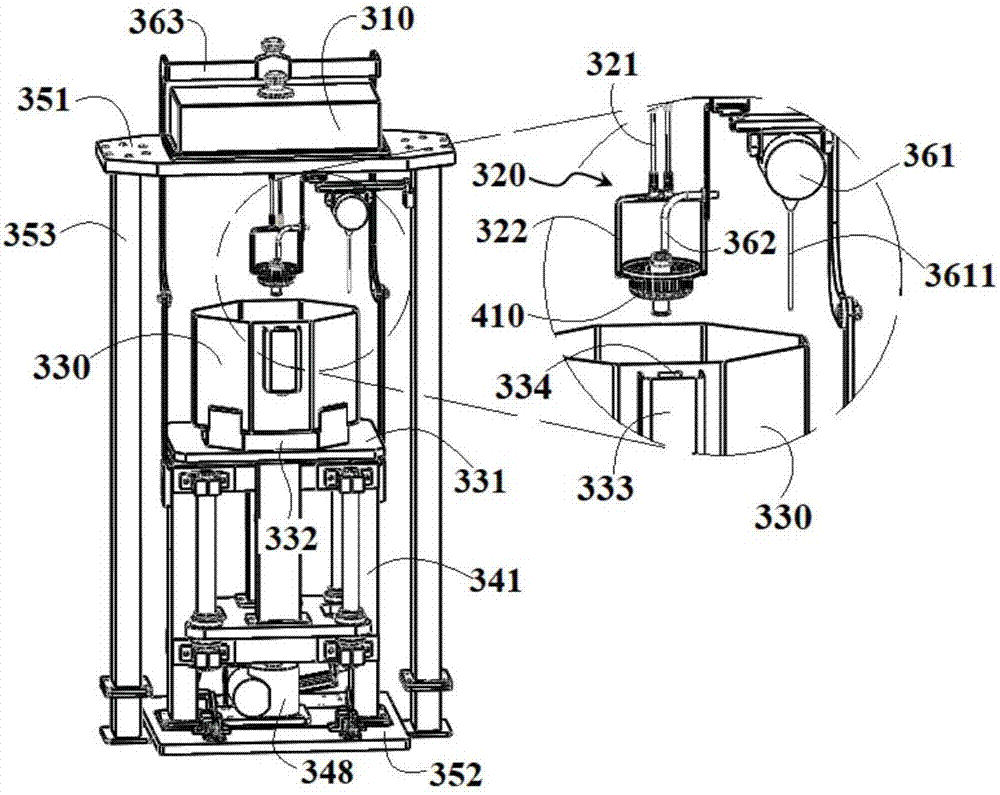

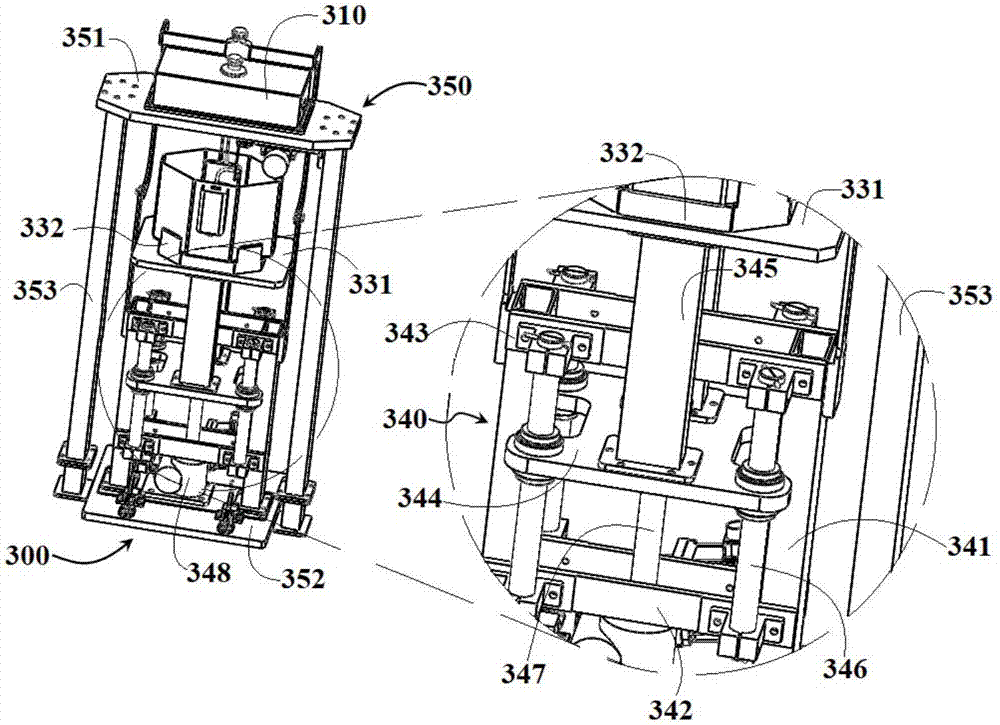

[0059] combine Figure 1-Figure 15 , a robot system for detecting density of the present invention includes a main robot unit 100, an auxiliary robot unit 200, a density detection unit 300, a stage unit 400 and a sample holding unit 500, wherein the main robot unit 100 includes a main mechanical gripper 101 and the main mechanical arm 102, the main mechanical gripper 101 is installed on the main mechanical arm 102, the main mechanical arm 102 drives the main mechanical gripper 101 to grab and move the object to be tested; the main robot unit 100, the auxiliary robot unit 200, the density The detection unit 300, the object stage unit 400 and the sample holding unit 500 are fixedly installed on the bottom plate platform 600 (such as figure 1 shown).

[0060] The main robot unit 100 includes a main mechanical gripper 101 and a main mechanical arm 102, the main mechanical gripper 101 is installed on the main mechanical arm 102, and the main mechanical arm 102 drives the main mech...

Embodiment 2

[0079] The basic content of this embodiment is the same as that of Embodiment 1, except that: the hanging basket support mechanism 430 of this embodiment is also provided with a dry air injection plate 433, and the dry air injection plate 433 is arranged on the lower part of the hanging basket support plate 432, and The dry air injection plate 433 is kept parallel to the hanging basket support plate 432, and the bottom air injection hole 4331 is arranged on the dry air injection plate 433, and high-temperature gas can be sprayed from the bottom air injection hole 4331, and the sample hanging basket 410 can be purged, so that the The air jet holes 4323 on the curved surface and the jet holes 4331 on the bottom further purify in multiple directions, which improves the purging effect, and cooperates with the basket support plate 432 to heat the sample hanging basket 410, so that the sample hanging basket 410 can be quickly carried out. Drying, thereby improving the detection accur...

Embodiment 3

[0081] The basic content of this embodiment is the same as that of Embodiment 1, except that the weight support mechanism 440 of this embodiment is used to carry weights, and the weights are used to calibrate the results of density detection. The specific calibration method is as follows: ρ 溶液 Measured by the following steps:

[0082] 1 Weigh the mass of the sample hanging basket 410 as m 01 ; After the sample hanging basket 410 is immersed in the solution, weigh the quality of the sample hanging basket 410 as m 02 ;

[0083] 2 Add the weight into the sample hanging basket 410, and weigh the mass of the sample hanging basket 410 and the weight as m 21 ; After the sample hanging basket 410 and the weight are immersed in the solution, the quality of the weighing sample hanging basket 410 and the weight is m 22 ;

[0084] 3 Calculation of solution density ρ 溶液 ; Calculate the density ρ of the item to be tested by the following formula 溶液 ,

[0085] where m 砝 is the mas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com