A preparation method of quantum dot color filter film based on self-assembly

A technology of quantum dots and color filter films, applied in the display field, can solve the problems of brightness and color gamut not comparable to quantum dots, high production cost, low utilization rate of raw materials, etc., and achieves the effect of improving light leakage and complete structure and function.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

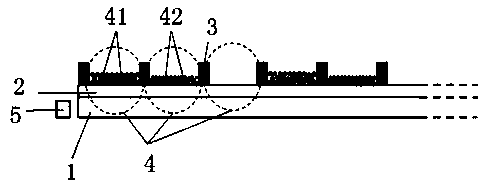

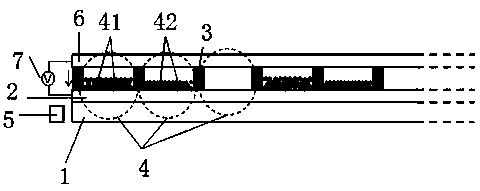

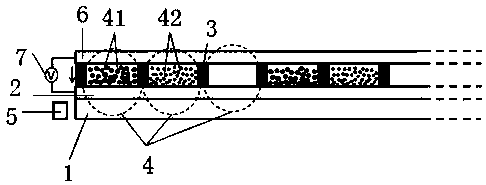

[0037] A method for preparing a self-assembly-based quantum dot color filter provided by the present invention will be described in detail below with reference to the accompanying drawings and examples. The present invention provides preferred embodiments, which are only used for further description of the present invention, and should not be considered as being limited to the embodiments set forth herein, nor can they be interpreted as limiting the protection scope of the present invention. Some non-essential improvements and adjustments made to the present invention still belong to the protection scope of the present invention. In this patent, the quantum dot color filter film structure should not be regarded as strictly specifying its parameters and geometric dimensions. Here, the referenced figures are schematic diagrams of idealized embodiments of the present invention, and the illustrated embodiments of the present invention should not be considered limited to the specif...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com