A method for improving thermal stability of luminescent materials

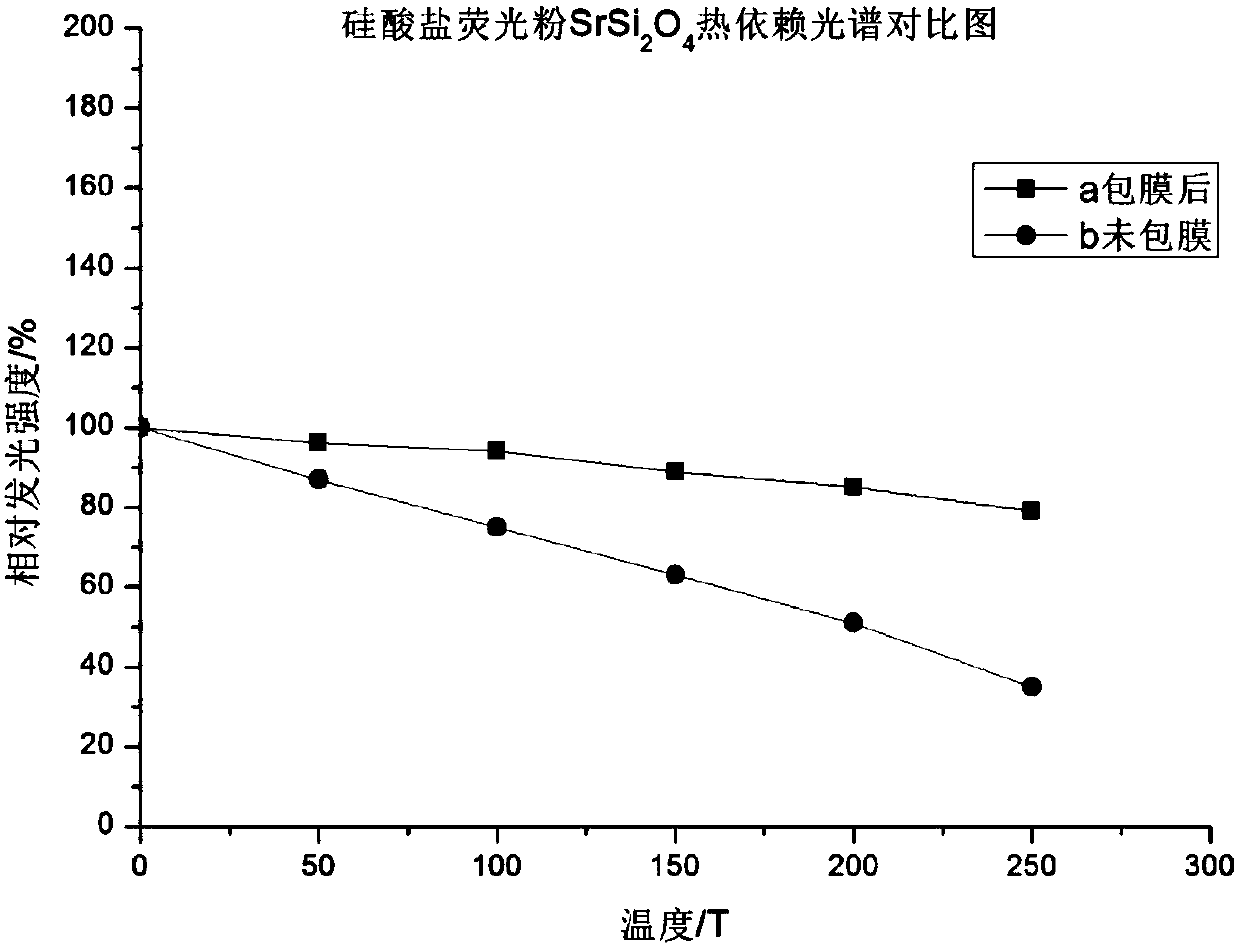

A technology of luminescent materials and thermal stability, which is applied in the field of luminescent material modification, can solve the problems that other materials have not been tried and the coating thickness cannot be controlled, no explanation is made, and the process setting is not explained, so as to achieve controllable coating thickness , the effect of high luminous intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

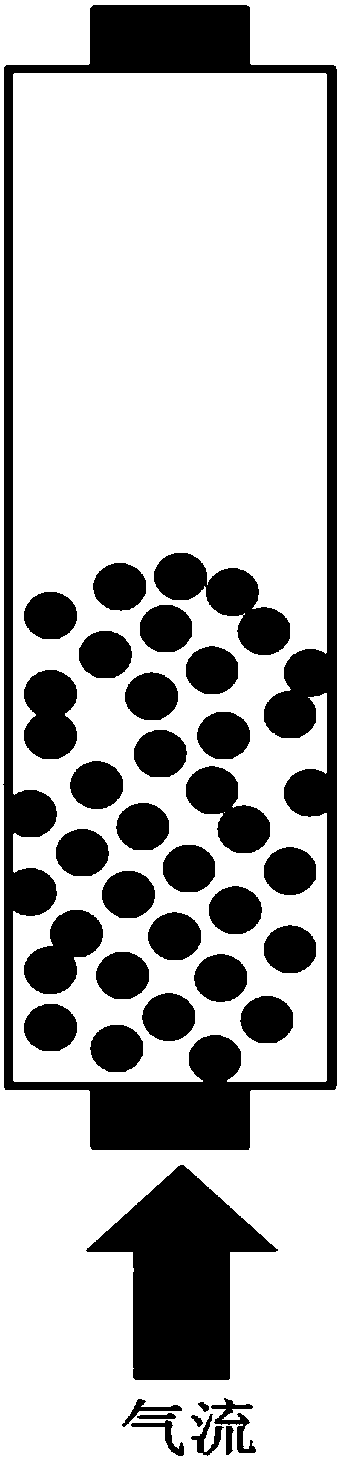

[0047] Coated SrSi 2 o 4 : Eu 2+ Phosphor powder samples are subjected to particle size classification through a 400-mesh vibrating sieve to obtain samples with a particle size of 1-10 microns, which are coated with a fluidized bed (shown in the comments) image 3 ), select alumina as the coating material, trimethylaluminum as the metal organic gas aluminum source, nitrogen as the carrier gas, and water as the oxide, and the residence time of each gas is: nitrogen: metal organic gas: nitrogen: oxygen = 2min; 20min; 10min; 0.5min. Sampling was performed at the 40th cycle, the 80th cycle, the 120th cycle, the 160th cycle, and the 200th cycle. Through transmission electron microscopy (TEM) the thickness of the film material of the film material on the surface of the material (see Table 1), EDS assisted to determine that the aluminum content of the coating layer increased significantly, and basically no silicon element could be observed after 200 cycles (see Table 1). The TEM ...

Embodiment 2

[0051] The enveloped CaS:Eu 2+Phosphor powder samples are subjected to particle size classification through a 500-mesh vibrating sieve to obtain samples with a particle size of less than 1 micron, which are coated in a fluidized bed reactor (shown in the comments) image 3 ), select alumina as the coating material, trimethylaluminum as the aluminum source, nitrogen as the carrier gas, and water as the oxide, and the residence time of each gas is: nitrogen: metal organic gas: nitrogen: oxygen = 2min; 20min; 10min ; 0.5 min. Sampling was performed at the 40th cycle, the 80th cycle, the 120th cycle, the 160th cycle, and the 200th cycle. Through the thickness of the film material of the film material on the surface of the material by transmission electron microscopy (TEM) (see Table 2), EDS assisted to determine that the aluminum content of the coating layer increased significantly, and basically no calcium element could be observed after 200 cycles (see Table 2).

[0052] Table...

Embodiment 3

[0055] The enveloped CaS:Eu 2+ Phosphor powder samples are subjected to particle size classification through a 400-mesh vibrating sieve to obtain samples with a particle size below 1 micron, which are coated with a vibrating bed (showing opinions Figure 5 ), select titanium oxide as the coating material, dicarbonyl bis(cyclopentadienyl) titanium as the titanium source, nitrogen as the carrier gas, and water as the oxide, and the residence time of each gas is: nitrogen: metal organic gas: nitrogen: Oxygen = 2min; 20min; 10min; 0.5min. Sampling was performed at the 40th cycle, the 80th cycle, the 120th cycle, the 160th cycle, and the 200th cycle. Through the thickness of the film material of the film material on the surface of the material by transmission electron microscopy (TEM) (see Table 3), EDS assisted to determine that the titanium content of the coating layer increased significantly, and basically no calcium element could be observed after 200 cycles (see Table 3).

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com