High-response-speed fuse

A technology of response speed and fuse, applied in electrical components, electrical switches, circuits, etc., can solve problems such as short time, potential safety hazards, and loss of power for new energy vehicles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

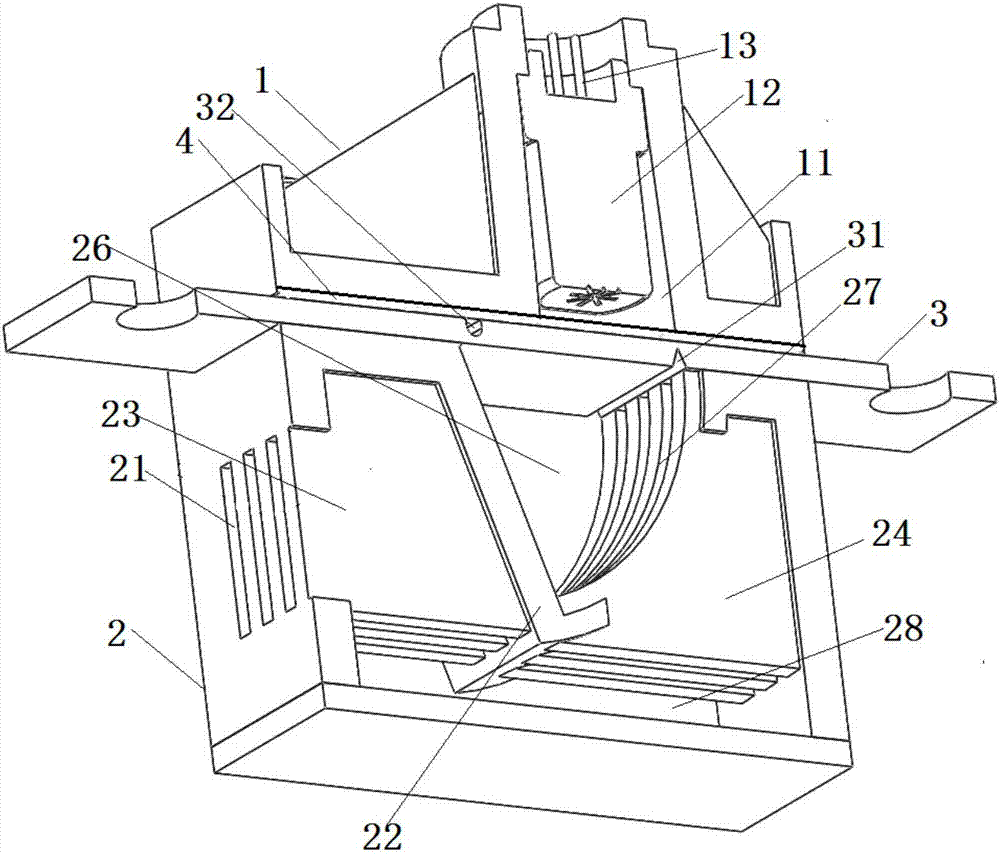

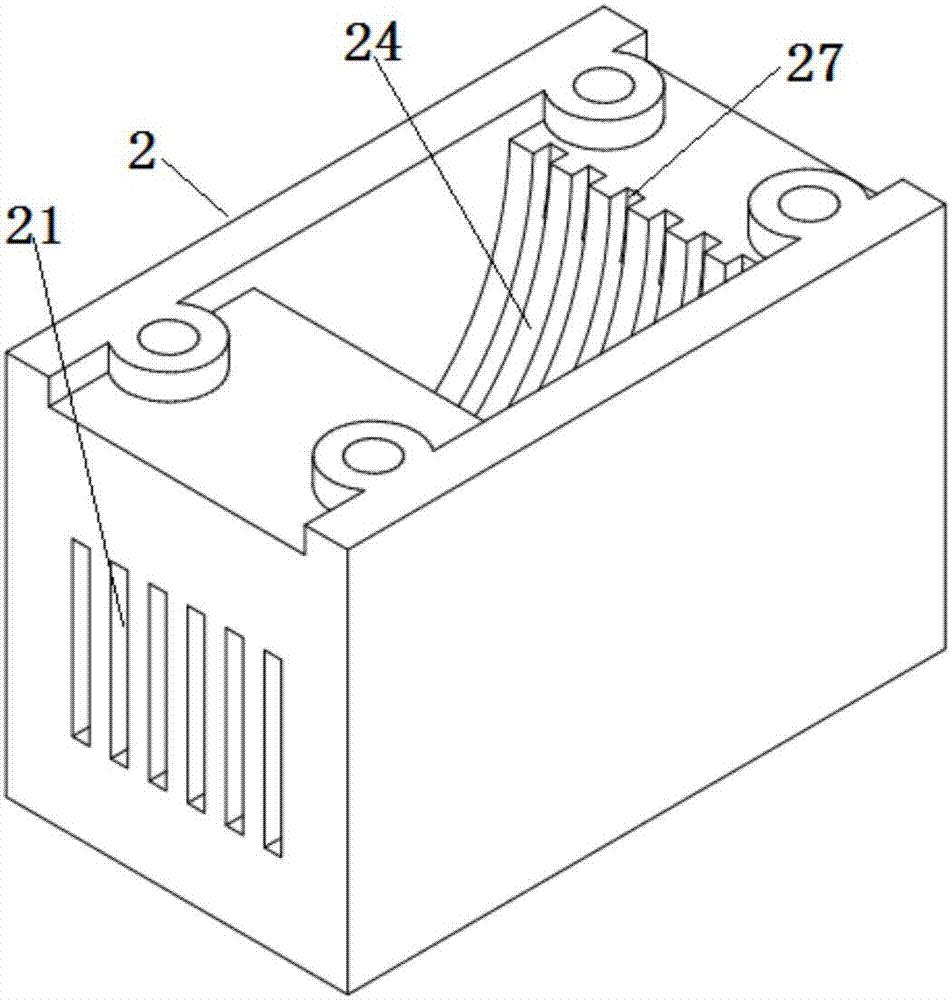

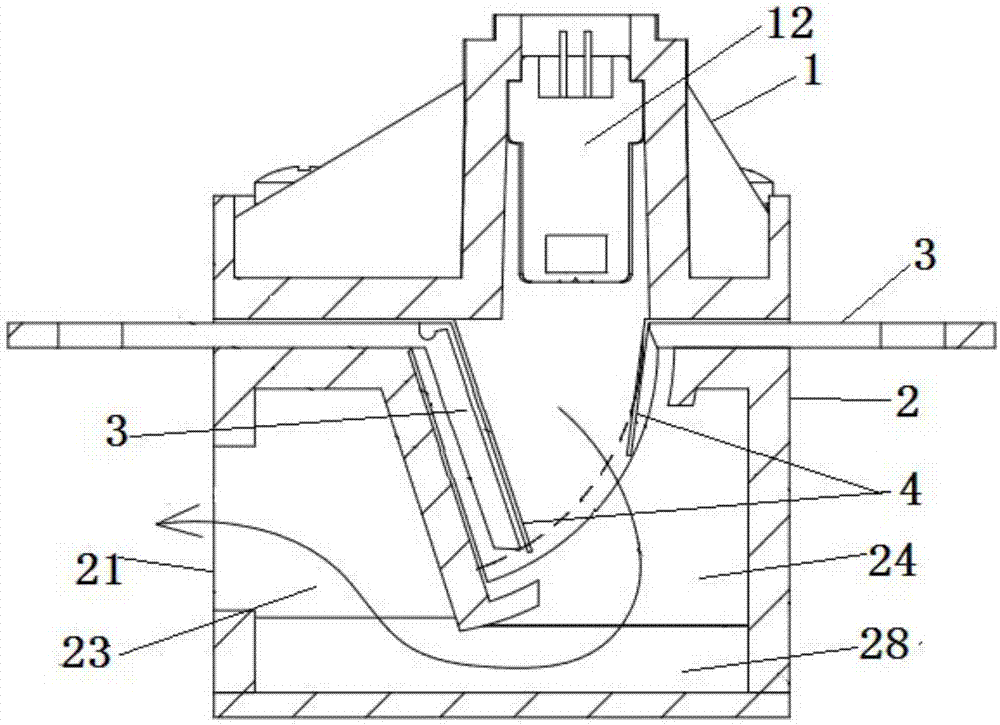

[0023] Aiming at the above-mentioned technical solution, a preferred embodiment is given and described in detail with reference to the drawings. see Figure 1 to Figure 3 , The fuse of the present invention includes an upper cover of the fuse, a lower case, and a conductive plate, wherein.

[0024] The upper cover 1 is set on the lower case 2, and a conductive plate 3 is arranged between the upper cover and the lower case. The upper cover 1 and the conductive plate 3 are fixed on the lower case by screws. A layer of insulating arc-extinguishing diaphragm 4 is arranged between the upper surface of the conductive plate 3 and the upper cover.

[0025] The upper cover 1 is provided with a cavity 11 as a combustion chamber, the upper end of the cavity 11 is sealed, and the lower end opening is located on the lower end surface of the upper cover. A gas generating device 12 is arranged in the cavity 11 . The gas generating device includes a powder chamber, an ignition device and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com