Long wire harness automatic threading machine and method

A technology of automatic pipe threading machine and pipe threading area, which is used in cable installation devices, electrical components, cable laying equipment, etc., can solve the problems of low working efficiency of artificial casing, difficult to meet the requirements of small pipe diameter and large length, etc., to save Time and energy, achieve the effect of automatic control, convenient work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

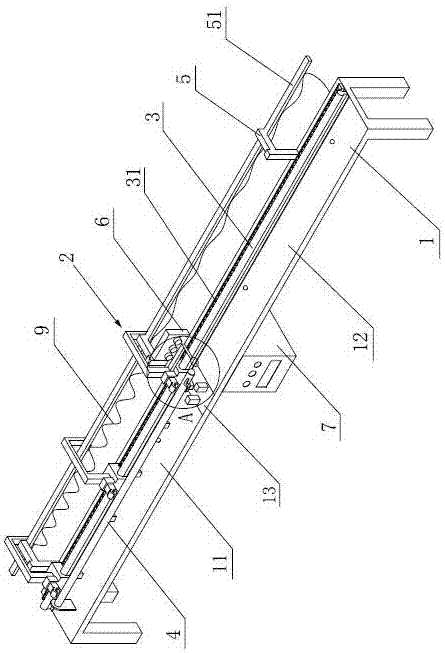

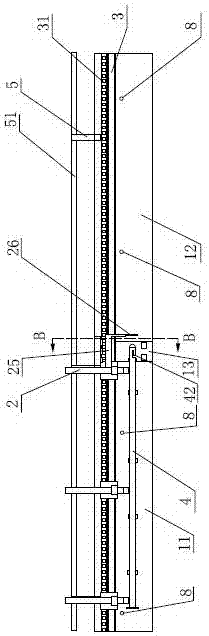

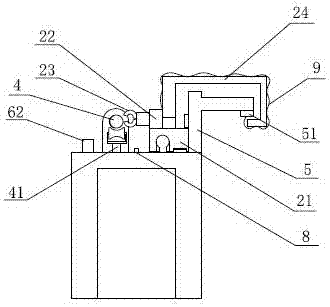

[0026] Such as figure 1 with figure 2 As shown, the long wire harness automatic pipe threading machine according to the present invention is provided with a guide rail 3, a threading rod 4, a clamping mechanism 2 and a control panel 6 above the workbench 1, and a controller 7 is arranged under the workbench 1. Several position sensors 8 are arranged on the table top 1 . The workbench has a long and narrow table, the length of which can reach 15 meters (for the convenience of display, the attached figure is a schematic diagram after reducing the length). Between 12 is tooling position 13. The guide rail 3 is arranged along the length direction of the workbench top 1, and the clamping mechanism 2 is driven by a drive chain 31 and can move along the guide rail 3.

[0027] The length of the threading rod 4 is shorter than the length of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com