Full-automatic soybean milk and bean curd integrated machine

An all-in-one, fully automatic technology, applied in the field of kitchen appliances, can solve the problems of inability to realize the fully automatic function of finished tofu, too many moving parts, and large floor space, so as to achieve safe and reliable operation of the machine, reduce workload, and prevent operational failures. The effect of rate reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

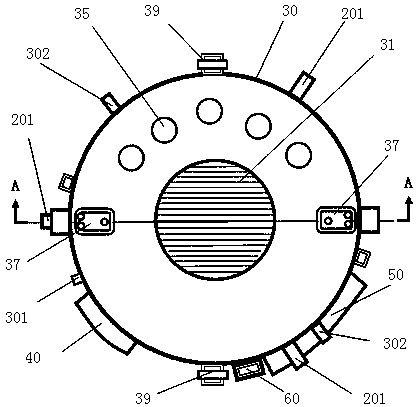

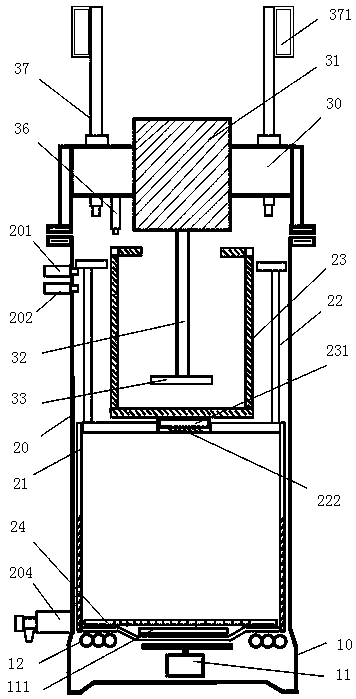

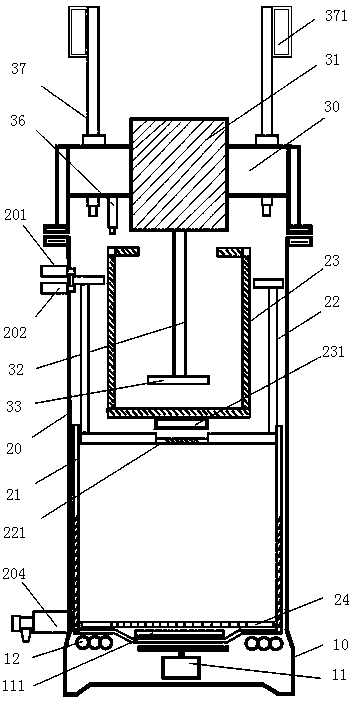

[0032] Such as Figure 1-7As shown, the fully automatic soybean milk and tofu all-in-one machine includes a base 10, a barrel body 20, a machine head 30, a coagulant solution cup 40, a water cup 50 and a water pump 60; a magnetic stirrer 11 and an electric heater are arranged inside the base 10 12. The coagulant solution cup 40, the water cup 50 and the water pump 60 are all fixed on the barrel body 20, and a temperature probe is installed at the bottom of the barrel body 20; a crushing motor 31 and a circuit control board are arranged inside the machine head 30, and the crushing motor 31 is connected with the crushing tool 33 through the cutter shaft 32. The coagulant solution inlet 34, the bean dregs washing inlet 35 and the rigid pressing member 37 are also arranged on the machine head 30. The anti-overflow probe 36 is installed at the lower end of the machine head, and the machine head 30 A coupler is set on the flange at the lower end, and a coupler is set on the flange o...

Embodiment 2

[0049] This embodiment is about the production of soybean milk, the coagulant solution cup 40, the squeeze barrel 21 and the rigid squeeze mechanism 37 do not participate in the production, and the rest of the configuration is basically the same as the first embodiment; from the perspective of the production process, the difference from the first embodiment is that After the program completes the pulp cooking process, it will not execute subsequent processes.

[0050] The specific production process is as follows:

[0051] Installing: Put the magnetic rotor 111 in the bottom groove of the clean barrel body 20, and then put the anti-off cover 24; buckle the cleaned refining barrel 22 on the first spring pin 201, put the filter barrel 23 Put it into the refining barrel 22, then screw the flange 232 of the filter barrel 23 into the slot on the barrel body 20; pour the soaked soybeans into the filter barrel 23, add water according to the required ratio, and ensure that the filter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com