Palladium nanoparticle/ceramic hydrogen permeation membrane composite material and preparation method thereof

A composite material, palladium nanotechnology, applied in separation methods, semi-permeable membrane separation, dispersed particle separation, etc., can solve the problems that the stability of palladium composite membranes affects commercial applications, etc., to improve reliability and stability, and good hydrogen resistance Brittleness, the effect of widening the use temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

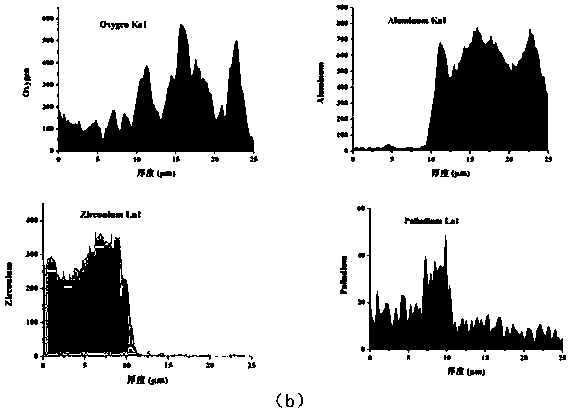

[0023] The porous ceramic support used is α-Al 2 o 3 / γ-Al 2 o 3 / ZrO 2 Asymmetric structure, tube length 50mm, tube diameter specification 14mm×12mm, ZrO 2 The separation layer (inside) had a pore diameter of 20 nm and a porosity of 60%.

[0024] a. The surface of the porous ceramic carrier is washed with absolute ethanol and deionized water and then dried at 120°C;

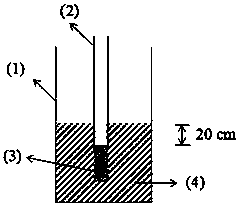

[0025] b. Place PdSO on the outside and inside of the cleaned porous ceramic carrier 4 Reagent (0.1mol / L) and SnCl 2 Reducing agent (0.1mol / L), keep the liquid level of reducing agent lower than PdSO 4 Reagent 20cm (see figure 1 ), after soaking for 24h, take out the porous ceramic carrier;

[0026] c. Take out the carrier, filter and wash the carrier in deionized water at a temperature of 40°C, and remove the residual liquid and organic matter remaining in the pores of the carrier;

[0027] d. Drying: the carrier is taken out, washed in deionized water, and dried at 150°C.

[0028] e. Repeat steps b-...

Embodiment 2

[0031] The porous ceramic support used is α-Al 2 o 3 / γ-Al 2 o 3 / ZrO 2 Asymmetric structure, tube length 50mm, tube diameter specification 14mm×12mm, ZrO 2 The separation layer (inside) has a pore diameter of 10 nm and a porosity of 30%.

[0032] a. The surface of the porous ceramic carrier is washed with absolute ethanol and deionized water and then dried at 120°C;

[0033] b. Place PdCl on the inside and outside of the porous ceramic carrier, respectively 2 Reagent (0.15mol / L) and reducing agent sodium formate (0.1mol / L), keep the liquid level of reducing agent lower than PdCl 2 Reagent 30cm, after soaking for 24h, take out the porous ceramic carrier;

[0034] c. Take out the carrier, filter and wash the carrier in deionized water at a temperature of 40°C, and remove the residual liquid and organic matter remaining in the pores of the carrier;

[0035] d. Drying: the carrier is taken out, washed in deionized water, and dried at 150°C.

[0036] e. Repeat steps b-d 1...

Embodiment 3

[0039] The porous ceramic support used is α-Al 2 o 3 / γ-Al 2 o 3 / γ-Al 2 o 3 Asymmetric structure, tube length 50mm, tube diameter specification 14mm×12mm, γ-Al 2 o 3 The separation layer (inside) has a pore diameter of 40 nm and a porosity of 50%.

[0040]a. The surface of the porous ceramic carrier is washed with absolute ethanol and deionized water and then dried at 120°C;

[0041] b. Place palladium acetate reagent (0.20mol / L) and reducing agent sodium formate (0.15mol / L) respectively on the inside and outside of the porous ceramic carrier to keep the liquid level of reducing agent lower than PdCl 2 Reagent 20cm, after soaking for 24h, take out the porous ceramic carrier;

[0042] c. Take out the carrier, filter and wash the carrier in deionized water at a temperature of 40°C, and remove the residual liquid and organic matter remaining in the pores of the carrier;

[0043] d. Drying: the carrier is taken out, washed in deionized water, and dried at 150°C.

[0044...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap