A high-efficiency mixer

A mixer, high-efficiency technology, applied to mixer accessories, mixers with rotating agitation devices, mixers, etc., can solve problems such as low efficiency, dust pollution, and worker hazards, and achieve improved work efficiency, increased mixing speed, and high efficiency The effect of stirring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

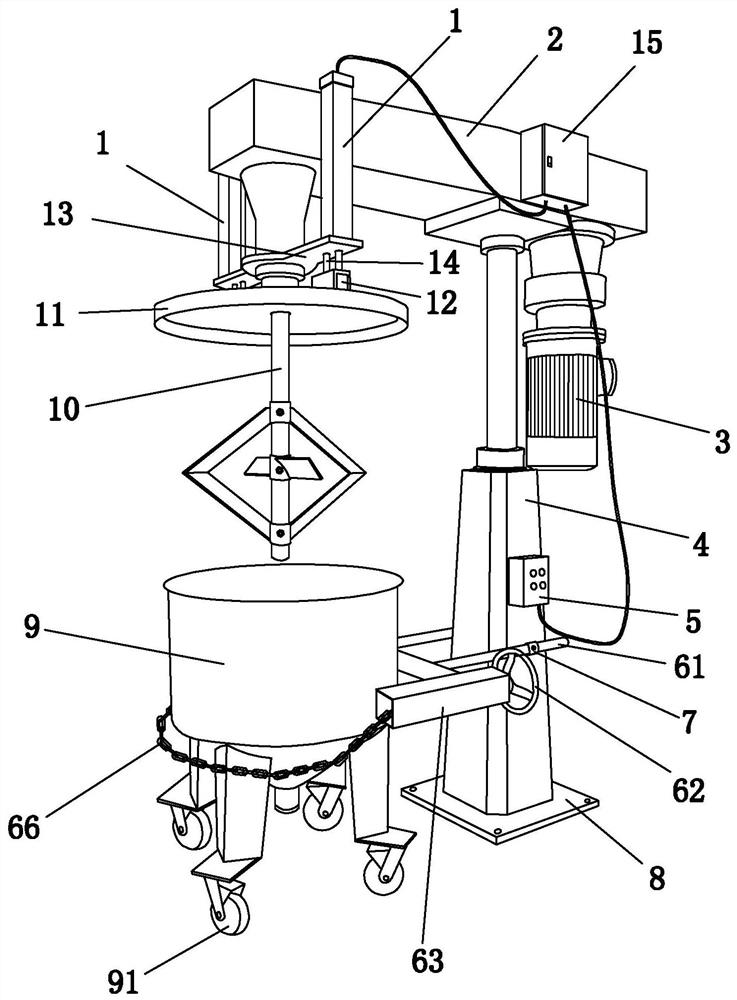

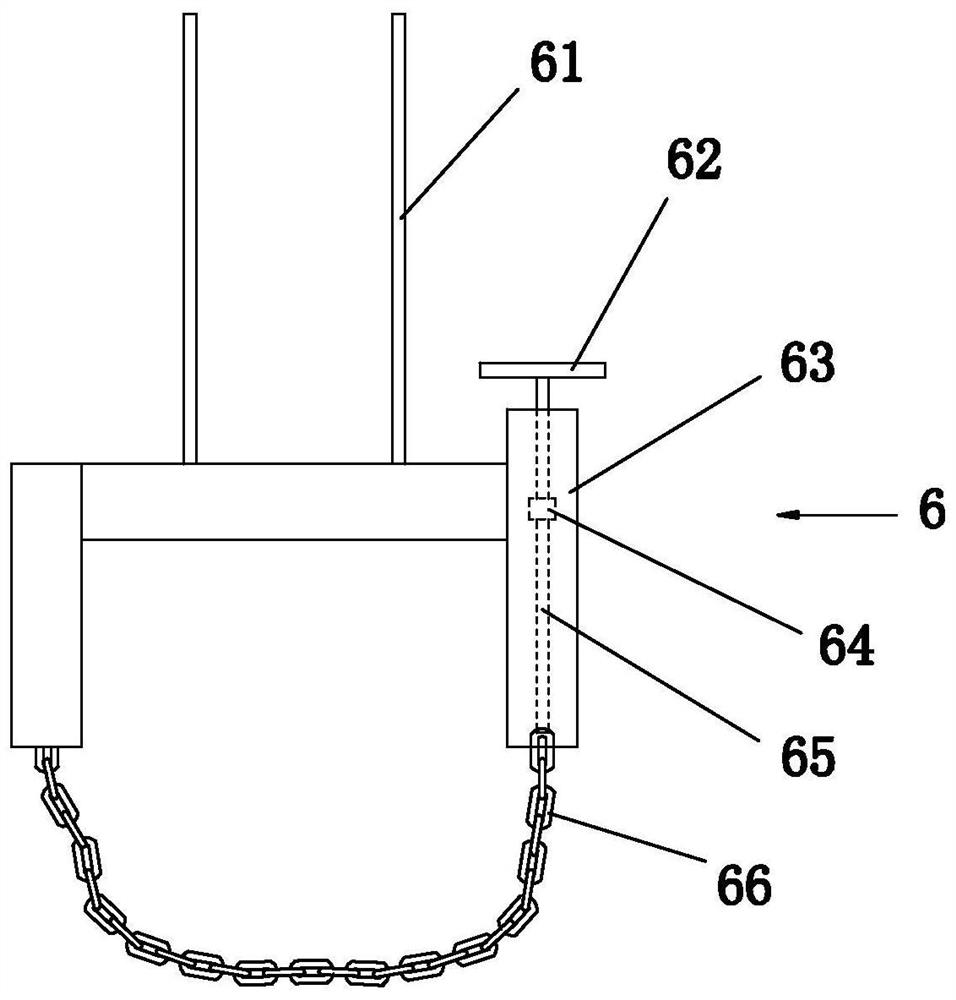

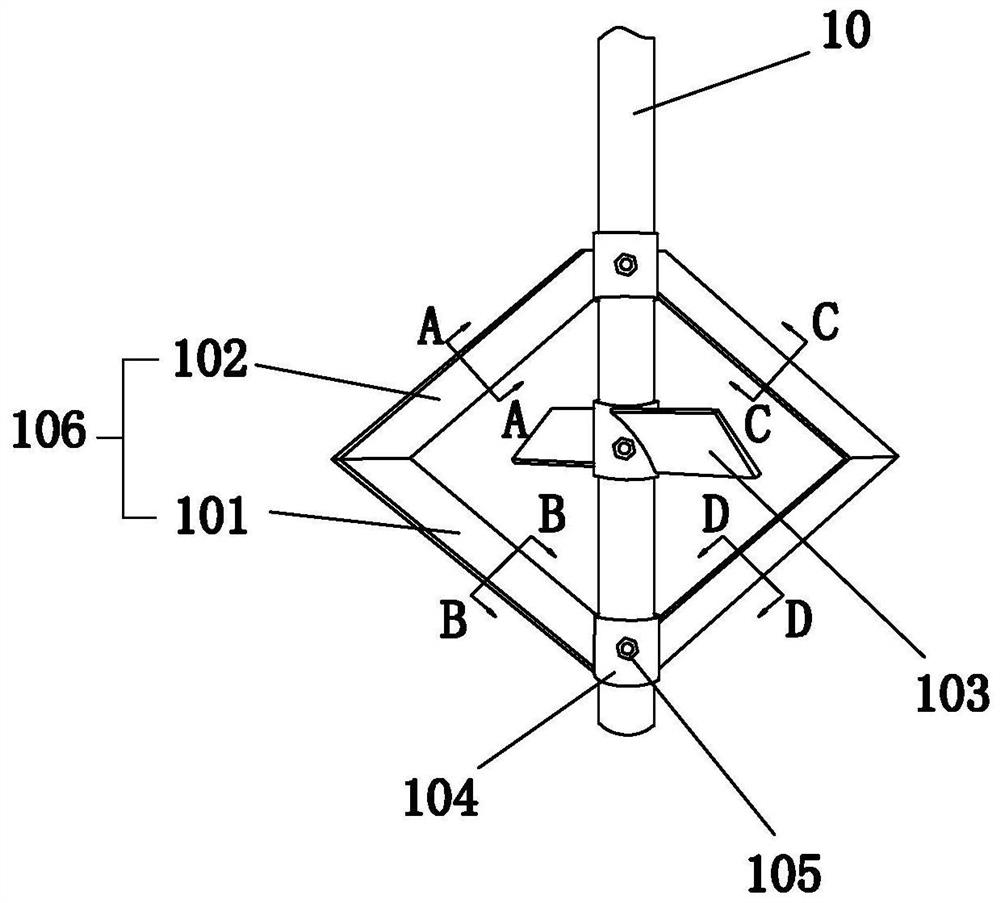

[0027] Such as figure 1 with figure 2 A high-efficiency mixer shown includes a mixer body, a mixing rod 10 and a motor 3. The mixer body includes a sealing cover 11, two electric telescopic rods 1, a fixed seat 8, a hydraulic telescopic rod 4, a mounting frame 2 and a fixed mixing barrel Frame 6.

[0028] The lower end of the fixing base 8 is a horizontal plate, and a fixing hole is opened on the horizontal plate, and the fixing hole is fixed on a horizontal installation surface by bolts. The hydraulic telescopic rod 4 is fixed on the fixed seat 8 vertically upwards. The hydraulic telescopic rod includes devices necessary for hydraulic control such as a hydraulic oil tank and an oil circuit. The hydraulic telescopic rod 4 drives the upper parts to move up and down to withstand greater force. Mounting frame 2 is horizontally fixed to the upper movable end of hydraulic telescopic rod 4, hydraulic telescopic rod 4 drives mounting frame 2 to move up and down, stirring rod 10 is inst...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap