Numerical control milling equipment

A technology of CNC milling and CNC milling machine, applied in milling machine equipment, metal processing equipment, milling machine and other directions, can solve the problems of difficult to achieve dimensional accuracy, inconsistent workpiece clamping force, high defect rate, improve processing efficiency and ensure consistent processing sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

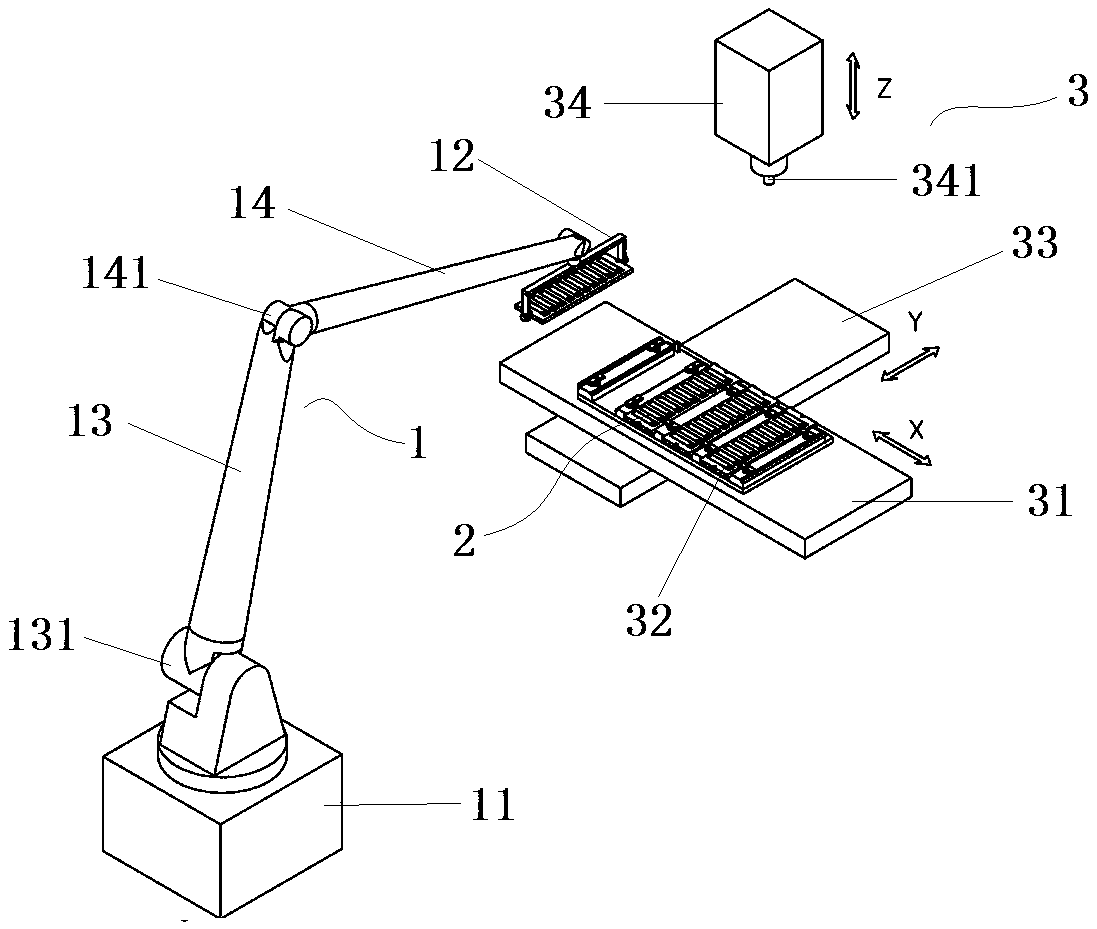

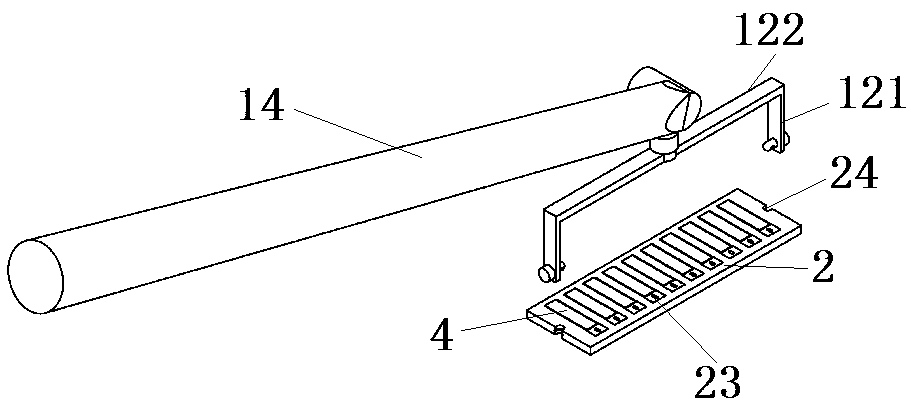

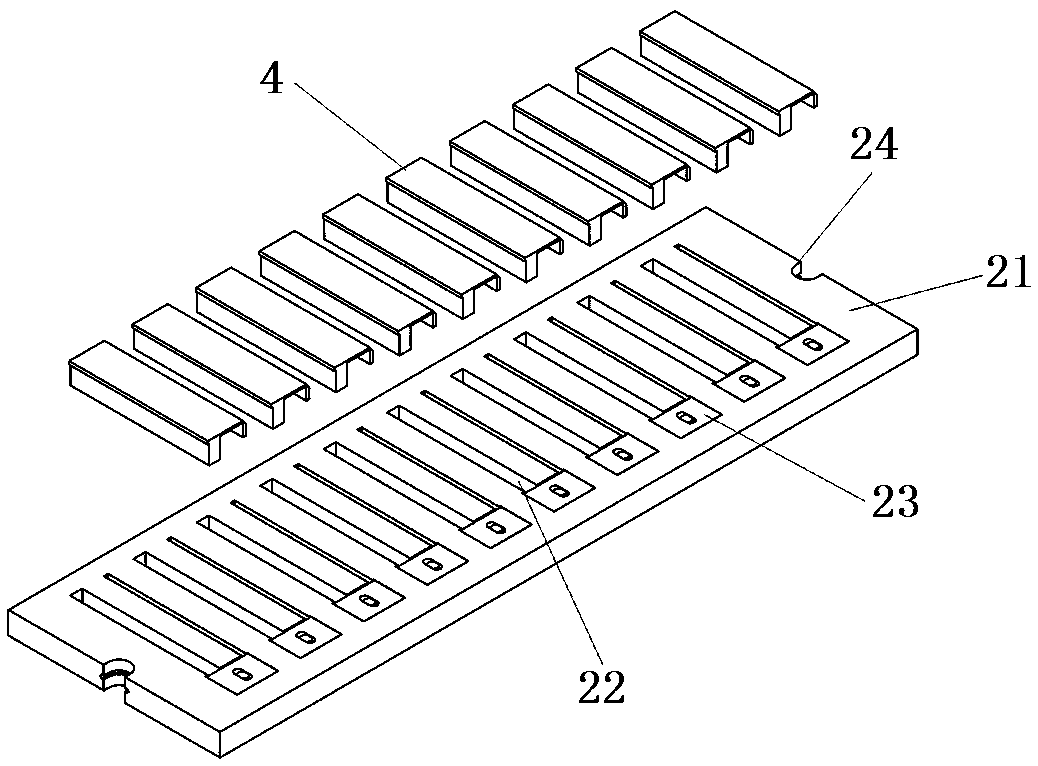

[0028] Such as figure 1 As shown, the present embodiment provides a kind of numerical control milling equipment, and this equipment comprises manipulator 1, turnover jig 2 and numerical control machine tool 3; The moving mechanism 33 and the Z-axis moving mechanism 34 are provided with a clamping fixture 32 for fixing the turnover fixture 2 on the X-axis moving mechanism; a milling cutter 341 for processing workpieces is provided on the Z-axis moving mechanism 34; A plurality of turnover jigs 2 are installed on the jig 311 . The turnover fixture 2 includes a base plate 21, the thickness of which is slightly smaller than the thickness of the workpiece 4, so that the two processed end faces of the workpiece 4 can be directly exposed on the two end faces of the base plate 21; the base plate 21 is provided with a plurali...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap