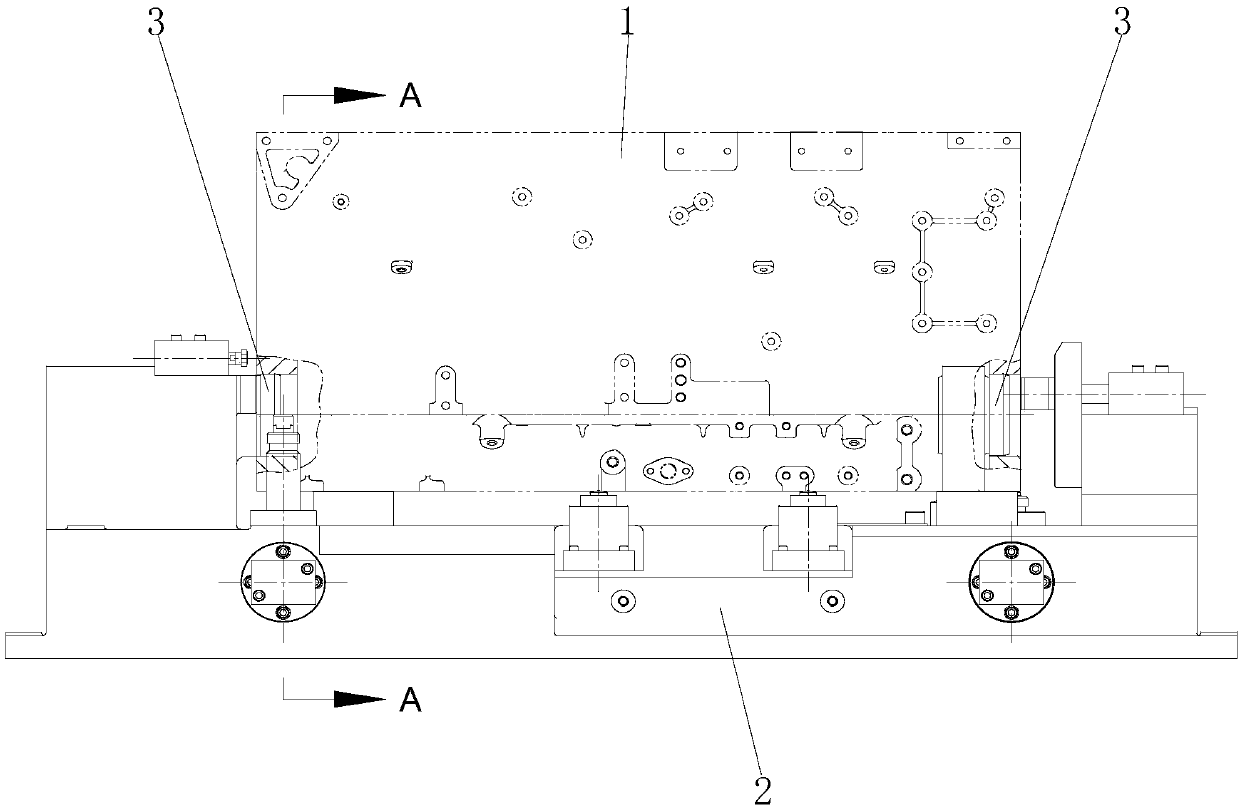

Positioning device for flattening bottom face of cylinder body

A technology of positioning device and cylinder block, applied in the direction of positioning device, clamping, supporting, etc., can solve the problems of inaccurate positioning of the cylinder block and affect the processing efficiency, so as to improve the positioning accuracy and clamping stability, improve the processing efficiency, Action-reliable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

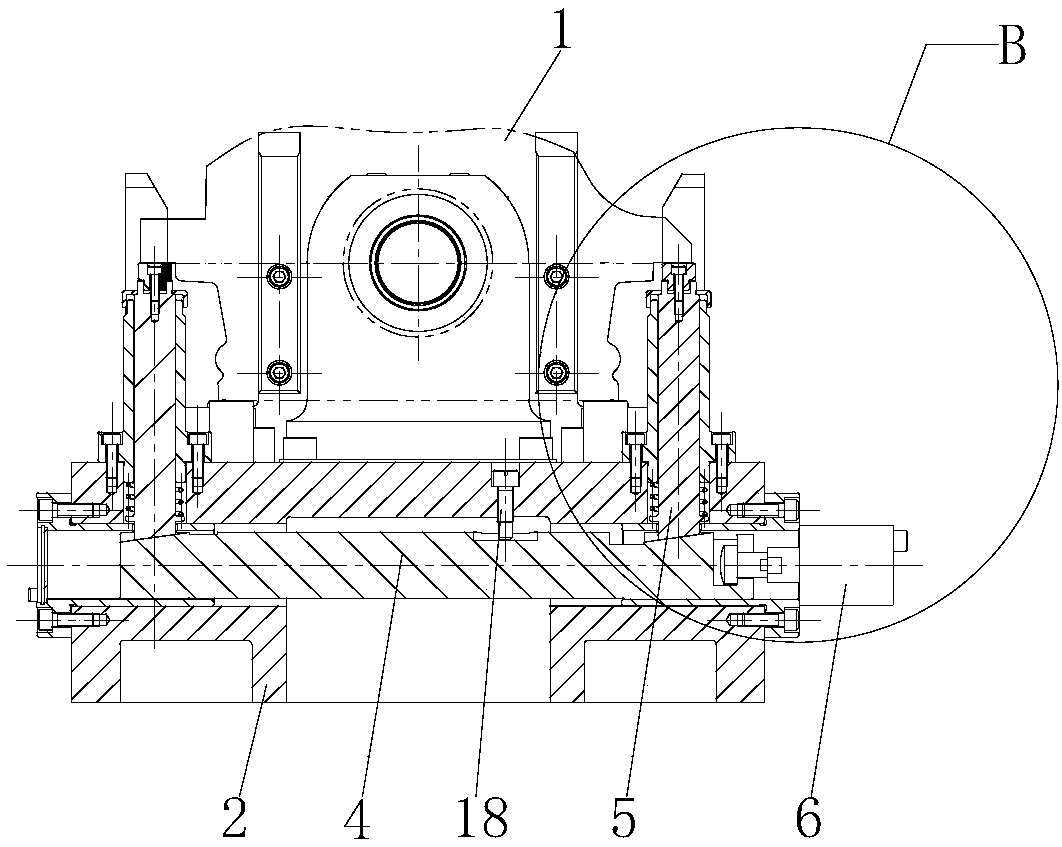

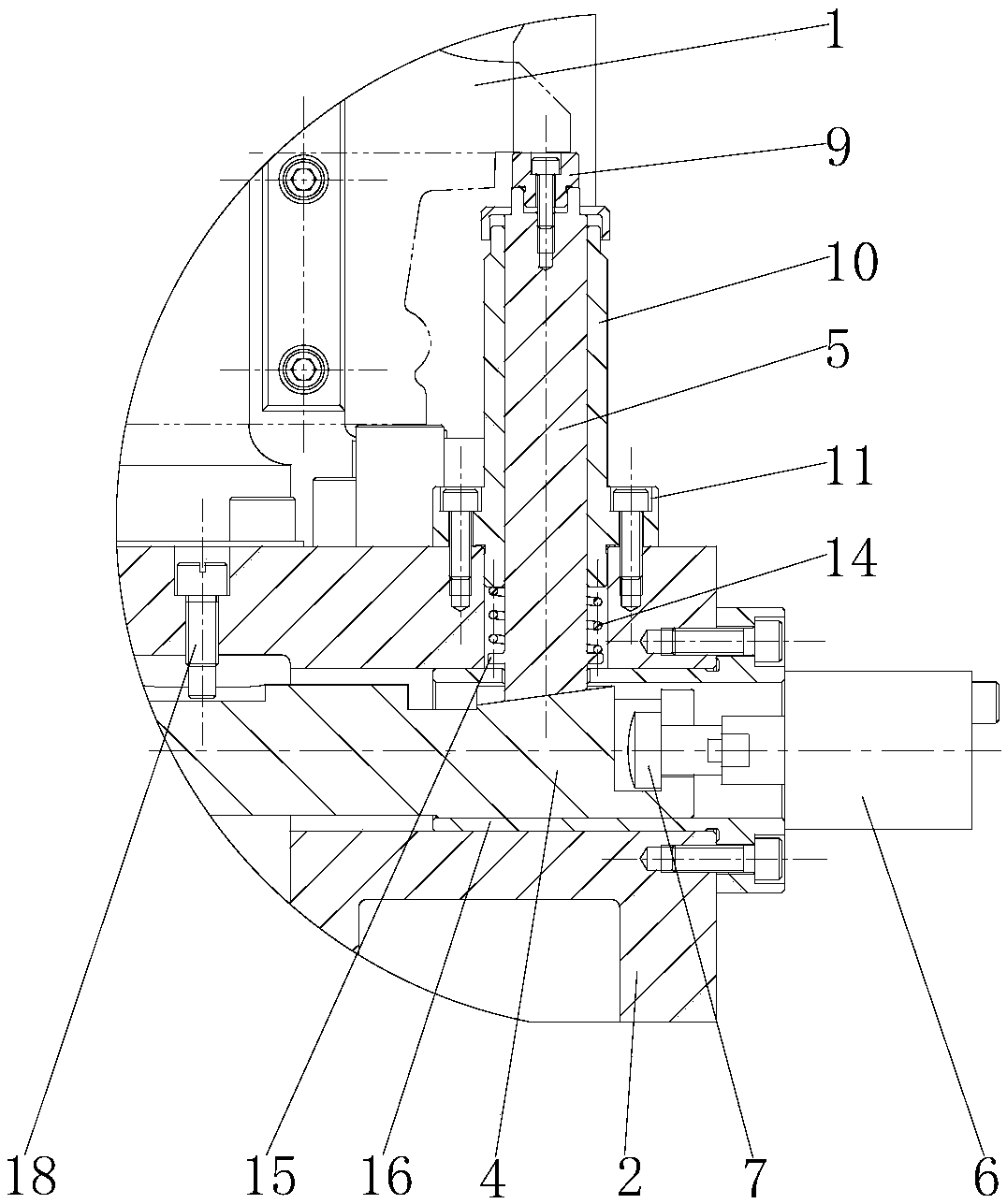

[0039] refer to Figure 1-4 , the two ends on the wedge iron 4 are respectively provided with wedge-shaped chute 13 with a positive inclination, correspondingly, the bottom of guide post 5 is provided with a connecting portion matching with wedge-shaped chute 13, and the inclination of wedge-shaped chute 13 The direction is consistent with the thrust direction of the driving device 6. When the driving device 6 drives the wedge iron 4 away from the driving device 6, the wedge-shaped chute 13 can push the two guide posts 5 to move upward at the same time until the two positioning blocks 9 and the cylinder block 1 The bottom surface is close until the cylinder block 1 is flattened and clamped. The present invention also includes a spring 14 sleeved on the lower part of the guide post 5. The lower part of the guide post 5 is provided with a limiting boss 15. One end of the spring 14 presses against the positioning guide sleeve 10 The lower end surface of the lower end, the other e...

Embodiment 2

[0051] refer to figure 1 , 7 -9, the two ends of the wedge iron 4 are respectively provided with reverse slope wedge-shaped dovetail grooves 12, correspondingly, the bottom of the guide post 5 is provided with a dovetail tenon matching the wedge-shaped dovetail groove 12, and the wedge-shaped dovetail groove 12 The inclination direction of the drive device 6 is opposite to the thrust direction of the drive device 6. When the drive device 6 drives the wedge iron 4 to approach the drive device 6, the wedge-shaped dovetail groove 12 can pull the two guide posts 5 to move upward at the same time until the two positioning blocks 9 and the cylinder block The bottom surface of 1 is close until the end is flat and clamped to the cylinder block 1. When the driving device 6 drives the wedge iron 4 away from the driving device 6, the wedge-shaped dovetail groove 12 can push the guide post 5 to move downward to realize the release of the cylinder block 1. The wedge-shaped dovetail groove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com