Equipment and method for chopping and dehydrating banana tree waste

A technology for dehydration equipment and waste, applied in cutting equipment, agricultural machinery and implements, agriculture, etc., can solve problems such as difficulty in meeting the requirements of differentiated dehydration rate, low degree of automation of dehydration process, uncontrollable dehydration rate, etc. The effect of improving dehydration efficiency, strong dehydration capacity and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

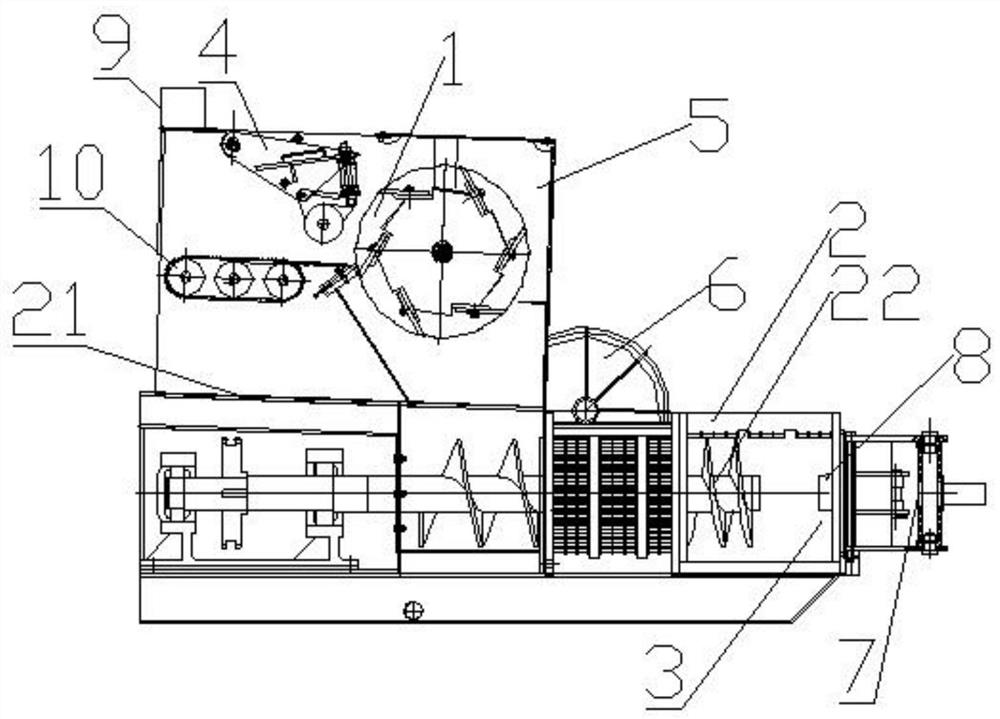

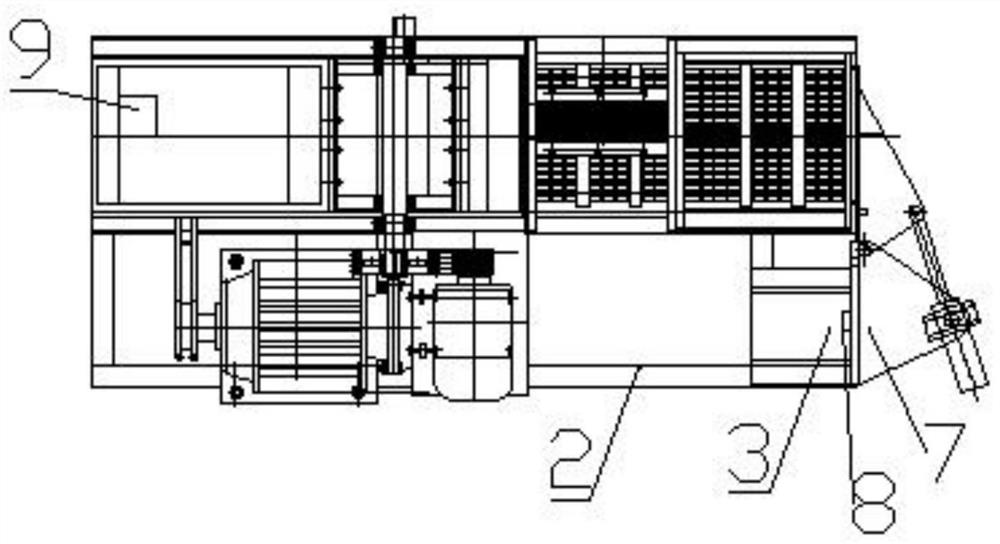

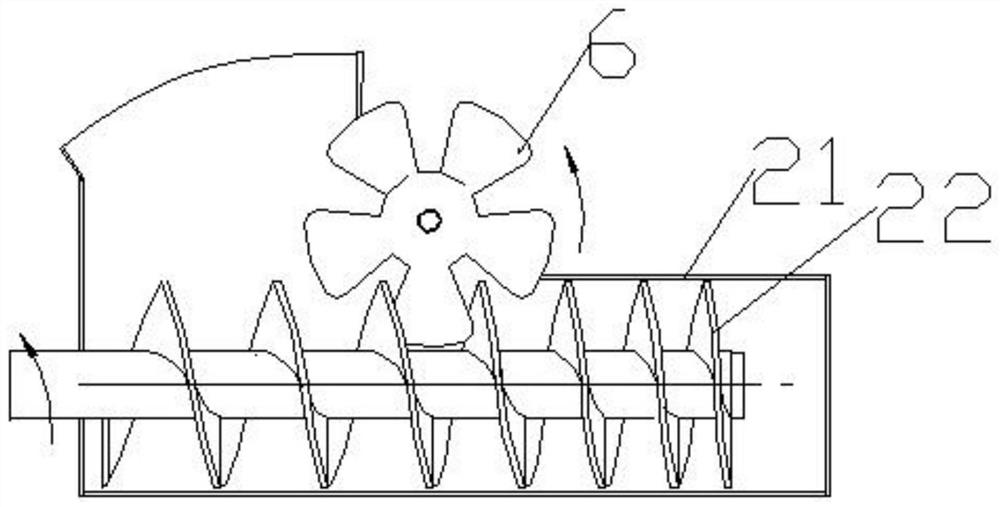

[0033] Such as figure 1 , figure 2 Shown: A cutting and dehydrating equipment for banana tree waste, including a cutting part (1), a pressing part (2), a discharge part (3), a pressing roller mechanism (4), a conveyor belt (10) and a frame (5), install the conveyor belt (10), pressing roller mechanism (4) and chopping part (1) sequentially from one side of the upper part of the frame (5), and the pressing part (2) is installed on the lower part of the frame (5) , the pressing part (2) includes a pressing chamber (21) and a spiral structure (22) in the pressing chamber (21), the discharge part (3) is installed at the end of the pressing part (2), and the chopping part (1) is located at the Above the part (2), it also includes a forced feeding part (6), a blocking door (7), a detection device (8) and a control system (9). The forced feeding part (6) is installed between the pressing part (2) and the cutting part. Between the crushing part (1), the forced feeding part (6) is a...

Embodiment 2

[0044] Such as figure 1 , figure 2 Shown: A cutting and dehydrating equipment for banana tree waste, including a cutting part (1), a pressing part (2), a discharge part (3), a pressing roller mechanism (4), a conveyor belt (10) and a frame (5), install the conveyor belt (10), pressing roller mechanism (4) and chopping part (1) sequentially from one side of the upper part of the frame (5), and the pressing part (2) is installed on the lower part of the frame (5) , the pressing part (2) includes a pressing chamber (21) and a spiral structure (22) in the pressing chamber (21), the discharge part (3) is installed at the end of the pressing part (2), and the chopping part (1) is located at the Above the part (2), it also includes a forced feeding part (6), a blocking door (7), a detection device (8) and a control system (9). The forced feeding part (6) is installed between the pressing part (2) and the cutting part. Between the crushing part (1), the forced feeding part (6) is a...

Embodiment 3

[0055] Such as figure 1 , figure 2 Shown: A cutting and dehydrating equipment for banana tree waste, including a cutting part (1), a pressing part (2), a discharge part (3), a pressing roller mechanism (4), a conveyor belt (10) and a frame (5), install the conveyor belt (10), pressing roller mechanism (4) and chopping part (1) sequentially from one side of the upper part of the frame (5), and the pressing part (2) is installed on the lower part of the frame (5) , the pressing part (2) includes a pressing chamber (21) and a spiral structure (22) in the pressing chamber (21), the discharge part (3) is installed at the end of the pressing part (2), and the chopping part (1) is located at the Above the part (2), it also includes a forced feeding part (6), a blocking door (7), a detection device (8) and a control system (9). The forced feeding part (6) is installed between the pressing part (2) and the cutting part. Between the crushing part (1), the forced feeding part (6) is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com