Pneumatic tire

A technology of pneumatic tires and bead, which is applied to tire parts, bead, transportation and packaging, etc., can solve the problems of increased road noise and achieve the effects of suppressing the increase of road noise, suppressing road noise, and alleviating impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

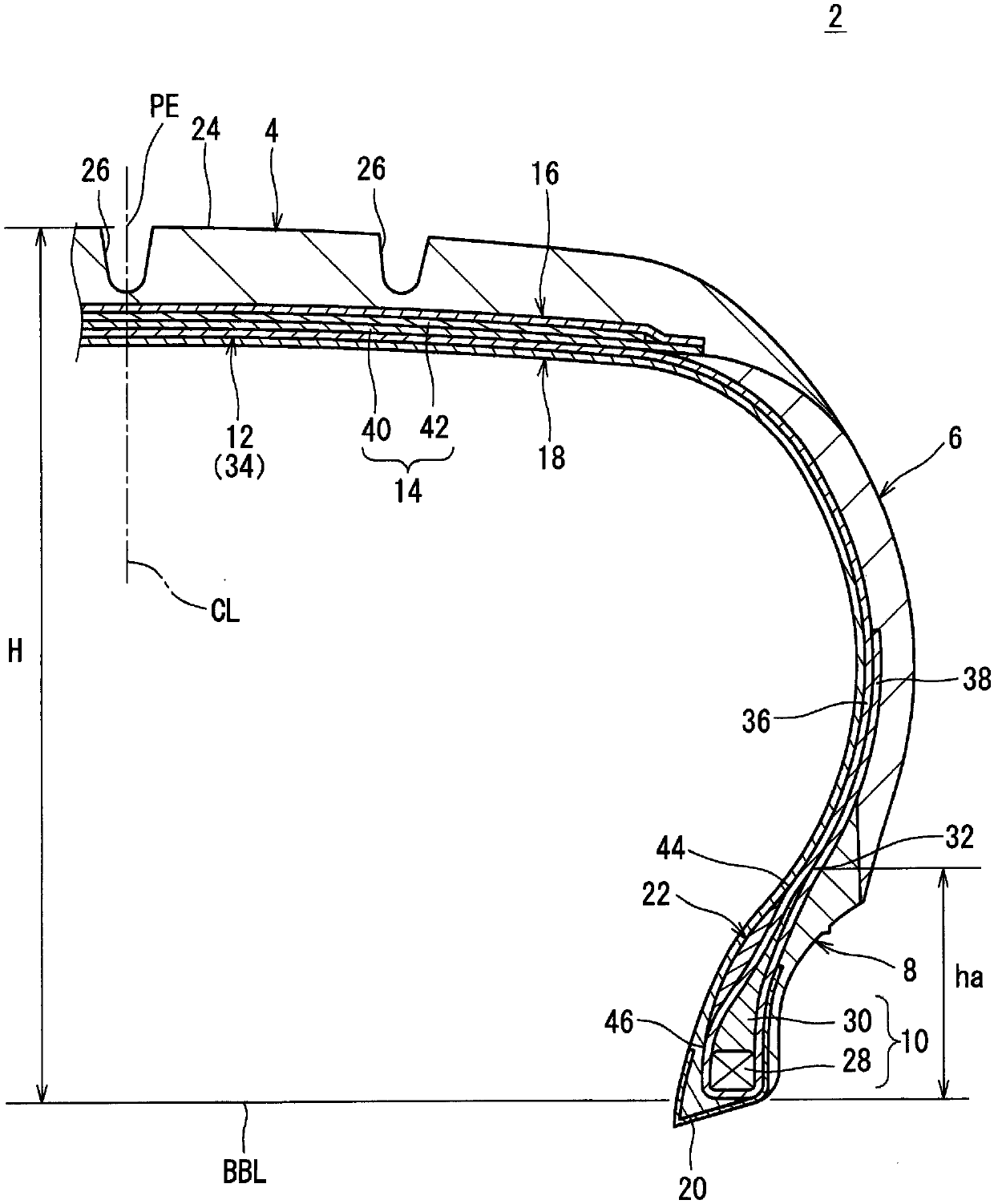

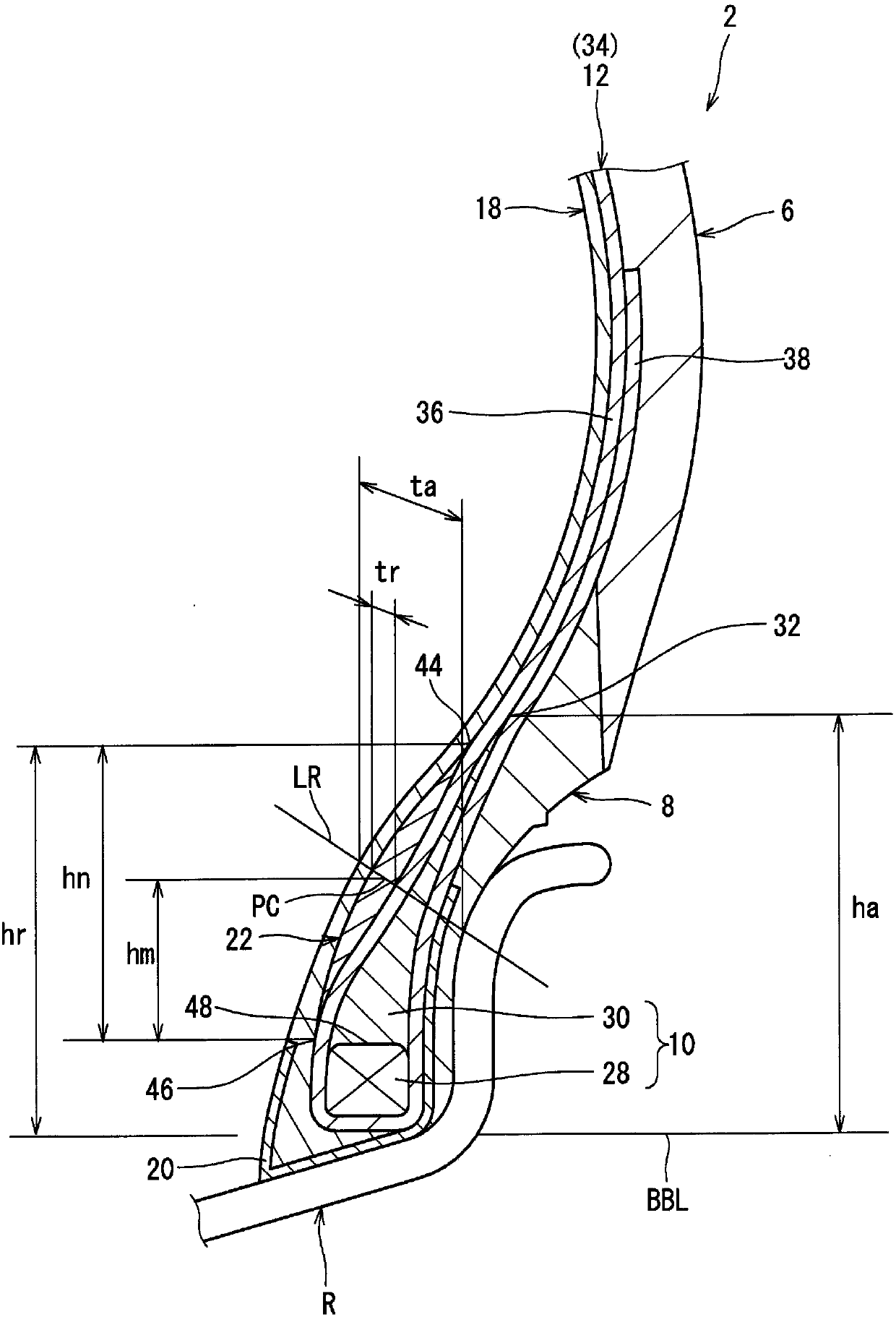

Embodiment 1

[0082] made Figures 1 to 2 tires shown. The tire size is 225 / 45R17 94W (rim width 7.5). In this Example 1, the hardness Hr of the reinforcing layer was set at 95. The maximum thickness tr of the reinforcement layer is 5.0 mm. The ratio (hr / ha) of the height hr in the radial direction of the reinforcing layer to the height ha in the radial direction of the apex (hr / ha) was set at 1.0. The hardness Ha of the apex is 90. Therefore, the difference (Hr−Ha) between the hardness Hr of the reinforcing layer and the hardness Ha of the apex is 5. The ratio of the height ha of the apex to the section height H of the tire (ha / H) was 0.25.

Embodiment 2~4

[0086] The thickness tr is as shown in the following Table 1, and the other is the same as that of Example 1, and the tires of Examples 2 to 4 were obtained.

Embodiment 5~8 and comparative example 2

[0088] The ratio (hr / ha) is as shown in the following Table 2, and the other is the same as that of Example 1, and the tires of Examples 5 to 8 and Comparative Example 2 were obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com