Concrete vibrator capable of adjusting frequency

A vibrator and concrete technology, which is applied in construction, building structure, construction material processing, etc., can solve the problems of easy damage to the driving mechanism, difficulty in changing the speed for a long time, etc., and achieve the effect of improving the vibration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

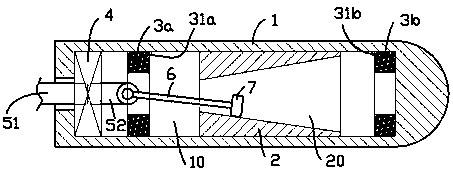

[0015] exist figure 1 In the first shown embodiment, the frequency-tunable concrete vibrator includes a rod-shaped base shell 1 made of non-ferromagnetic materials; an axial sliding cavity 10 is formed inside the base shell 1, and inside the sliding cavity 10 An iron slider 2 that can slide axially is matched, and a tapered cavity 20 is formed inside the slider 2, and the diameter of the front end of the tapered cavity 20 is larger than the diameter of the rear end; the two sides of the sliding area of the slider 2 An electromagnet 3a, 3b is provided on each side; the electromagnet 3a, 3b is electrically connected to the control module (not shown) outside the base shell 1; the control module only makes one or zero at the same time The electromagnet is energized; the rear end inside the base shell 1 is provided with a coupling 4 for connecting the flexible shaft 51 outside the base shell 1 and the rotating shaft 52 inside the base shell, and the free end of the rotating shaft...

Embodiment 2

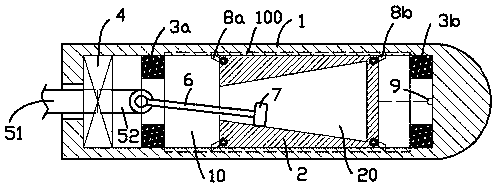

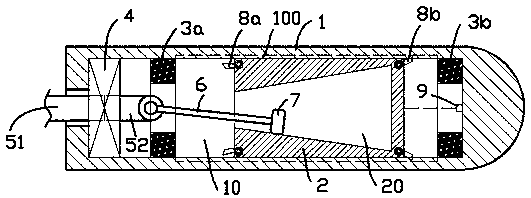

[0020] for figure 2 , image 3 The second embodiment shown is different from the first embodiment in that the end of the slider 2 has iron support blocks 8a, 8b connected by spring shafts. In a natural state, the iron support blocks 8a, 8b 8b leans outwards into the tooth groove 100 opened along the generatrix of the sliding chamber 10, so that the slider 2 is locked by the iron support blocks 8a, 8b and the tooth groove 100 and cannot be pushed into the iron support block. One end of the cog moves; figure 2 As shown, in the natural state, when the two electromagnets 3a, 3b are powered off, the iron support blocks 8a, 8b at both ends of the slider 2 are obliquely propped into the slots 100 opened along the generatrix of the sliding chamber 10 .

[0021] When the electromagnet is energized, the iron support block at the end close to the electromagnet on the slider 2 is drawn to the electromagnet under the action of magnetic attraction and deviates from the tooth groove 100,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com