Control system for constant current output of gas water heater fan

A constant current, control system technology, used in fluid heaters, lighting and heating equipment, etc., to solve problems such as reduced combustion efficiency, unbalanced ratio of gas and air, and excessive exhaust gas.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

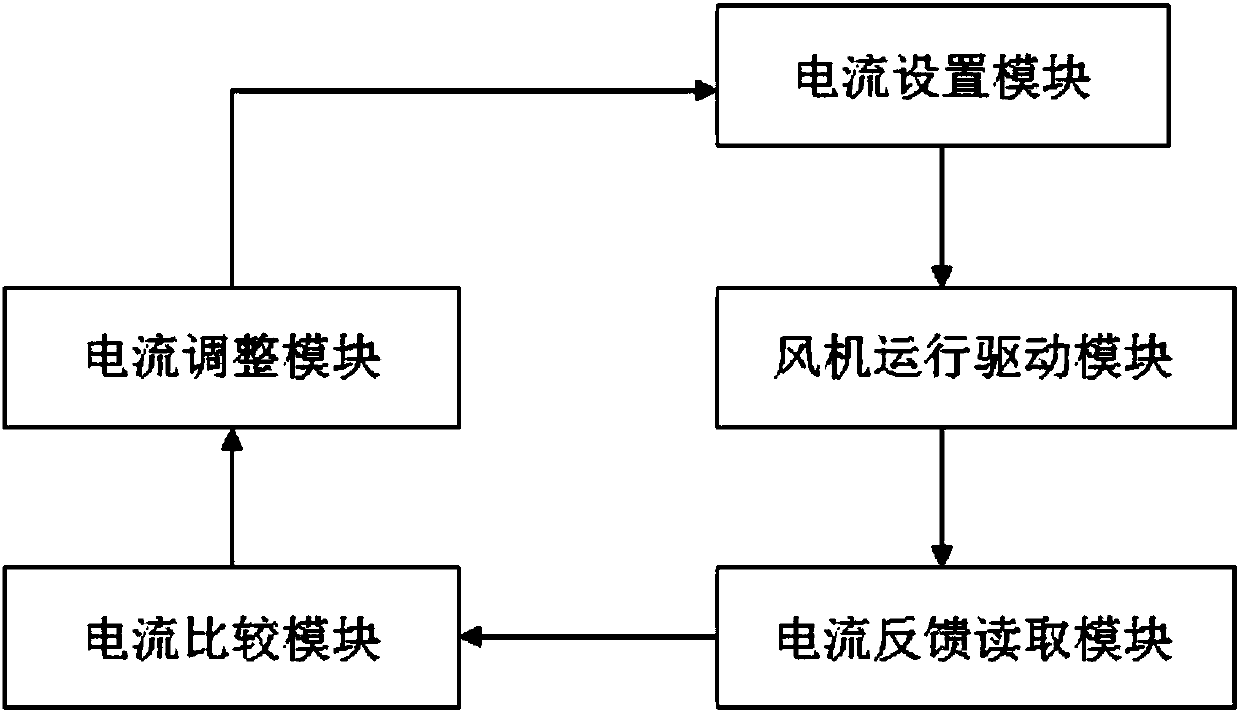

[0008] Please refer to figure 1 , a control system for constant current output of a fan of a gas water heater, comprising a current setting module, a fan operation drive module, a current feedback reading module, a current comparison module, and a current adjustment module, the current setting module determines the current setting value of the fan; The fan running drive module transmits the current setting value to the fan; the current feedback reading module reads the current output value of the fan; the current comparison module compares the read current output value with the current setting value , and determine the current difference; the current adjustment module converts the current difference into a PWM (Pulse Width Modulation, pulse width modulation) value and sends it to the current setting module.

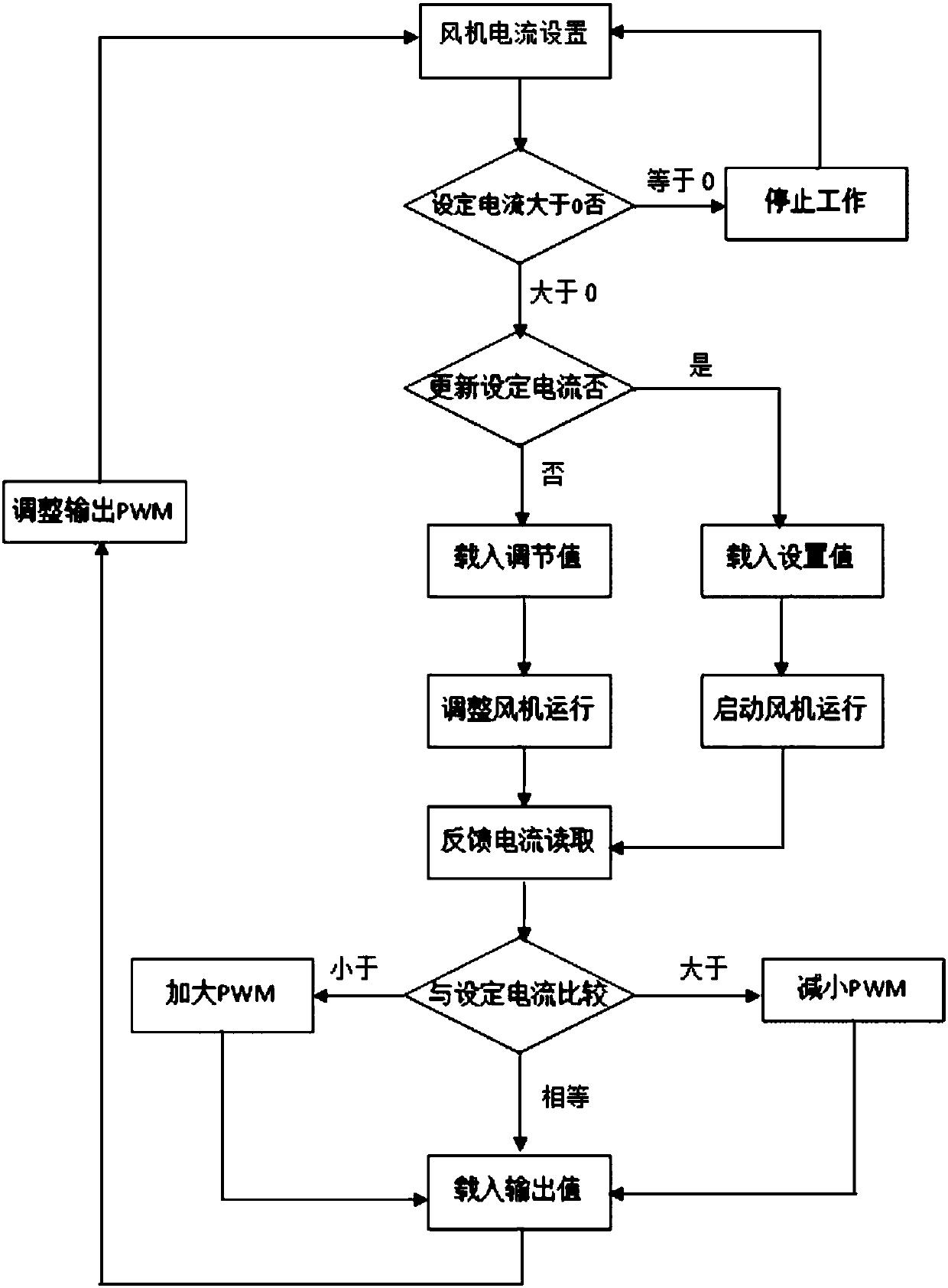

[0009] Please refer to figure 2 : Start the heater working fan setting program to calculate the corresponding current value of the fan according to the gas output. When...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com