Fault-tolerant control method for short-circuit faults of 90° phase-angle four-phase permanent magnet motors based on the principle of constant power

A short-circuit fault, constant power technology, applied in the direction of motor control, control system, electrical components, etc., can solve the problems of large torque fluctuation and weak motor torque output ability, and achieve the goal of reducing torque fluctuation and small copper loss Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The implementation of the present invention will be described in detail below in conjunction with the accompanying drawings and examples, so as to fully understand and implement the process of how to apply technical means to solve technical problems and achieve technical effects in the present invention. It should be noted that, as long as there is no conflict, each embodiment and each feature in each embodiment of the present invention can be combined with each other, and the formed technical solutions are all within the protection scope of the present invention.

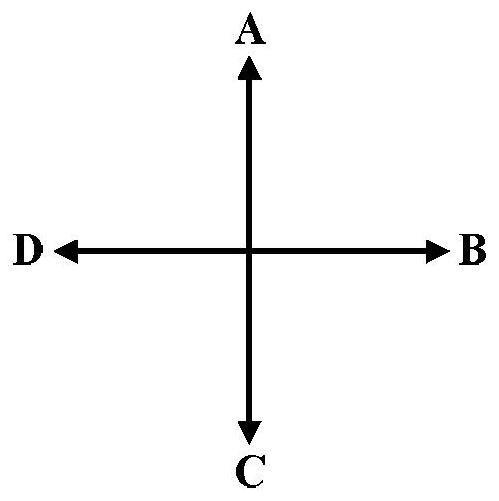

[0060] The fault-tolerant control method for short-circuit faults of four-phase permanent magnet motors with a 90° phase angle based on the principle of constant power described in this embodiment provides the situation that the instantaneous power of the four-phase motors remains unchanged before and after adjustment.

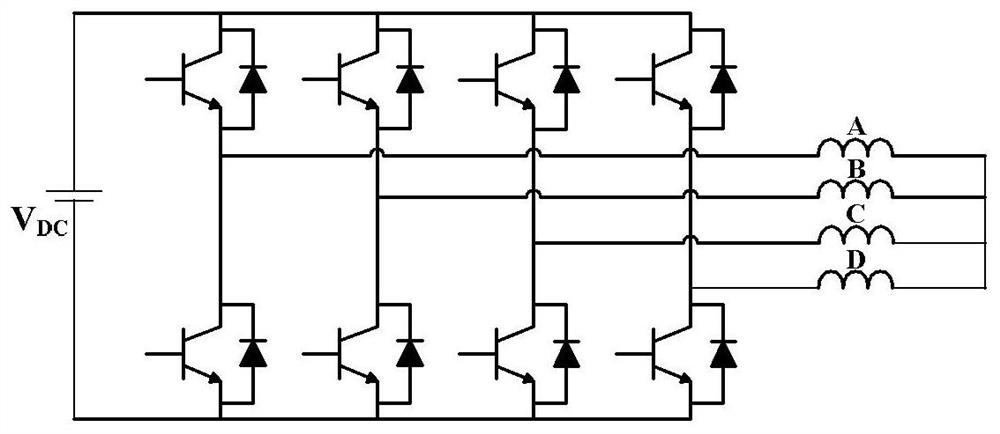

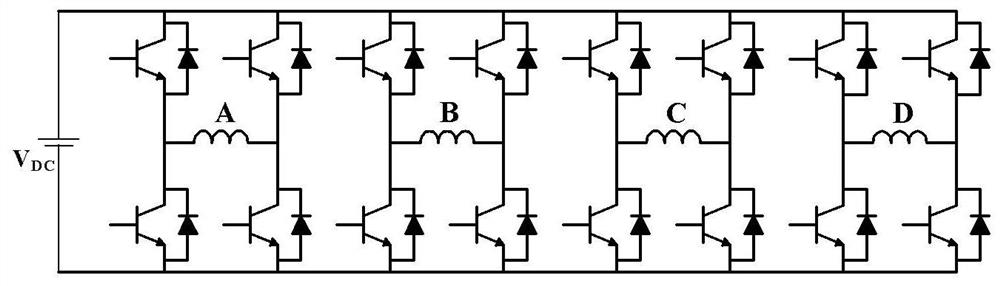

[0061] The schematic diagram of the power supply principle of a four-phase permanent magn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com