Apparatus and method for pretreating and printing textile surfaces

A pretreatment, fabric technology, applied in the direction of printing device, printing, fabric local treatment, etc., can solve the problem of pattern blur and achieve the effect of efficient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

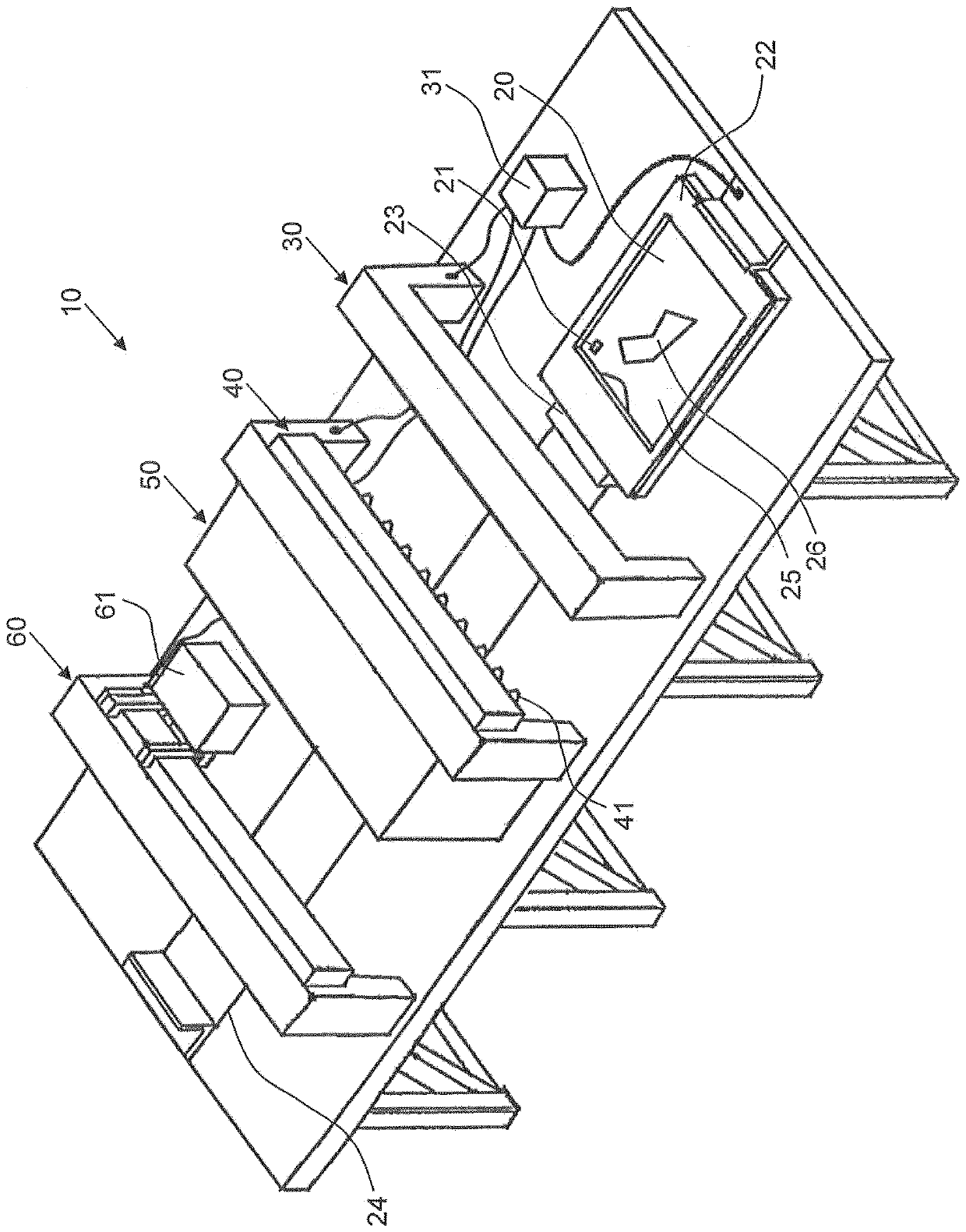

[0030] figure 1 An apparatus 10 for printing a textile surface is shown. The fabric 20 to be printed is arranged with its printing surface 25 on the pallet 22 in a setup position where the pallet 22 can be loaded with the fabric 20 . Via the movement device 23 the fabric 20 on the pallet 22 is supported in a movable manner along the guide rail 24 and can be successively transported to the individual devices of the device 10 . Starting from the set position, in the direction of movement of the pallet 22 , initially a detection device 30 is arranged, by means of which detection device the fabric 20 , more particularly the marks 21 on the fabric, can be detected by a programmable control device 31 . A programmable control device 31 is connected to all devices of the installation 10 . The information about the web 20 determined by the detection device 30 can be assigned to well-defined printing tasks by means of the programmable control device 31 . Print jobs can be transmitted...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com