Overflow steady liquid level type capsule production fluid discharge device

A technology for stabilizing liquid and capsules, which is applied in capsule delivery, drug delivery, pharmaceutical formulations, etc. It can solve the problems of capsule bubbles, glue dipped in the air, waste products, etc., and achieve the effect of ensuring stability, ensuring flow rate, and ensuring liquid level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

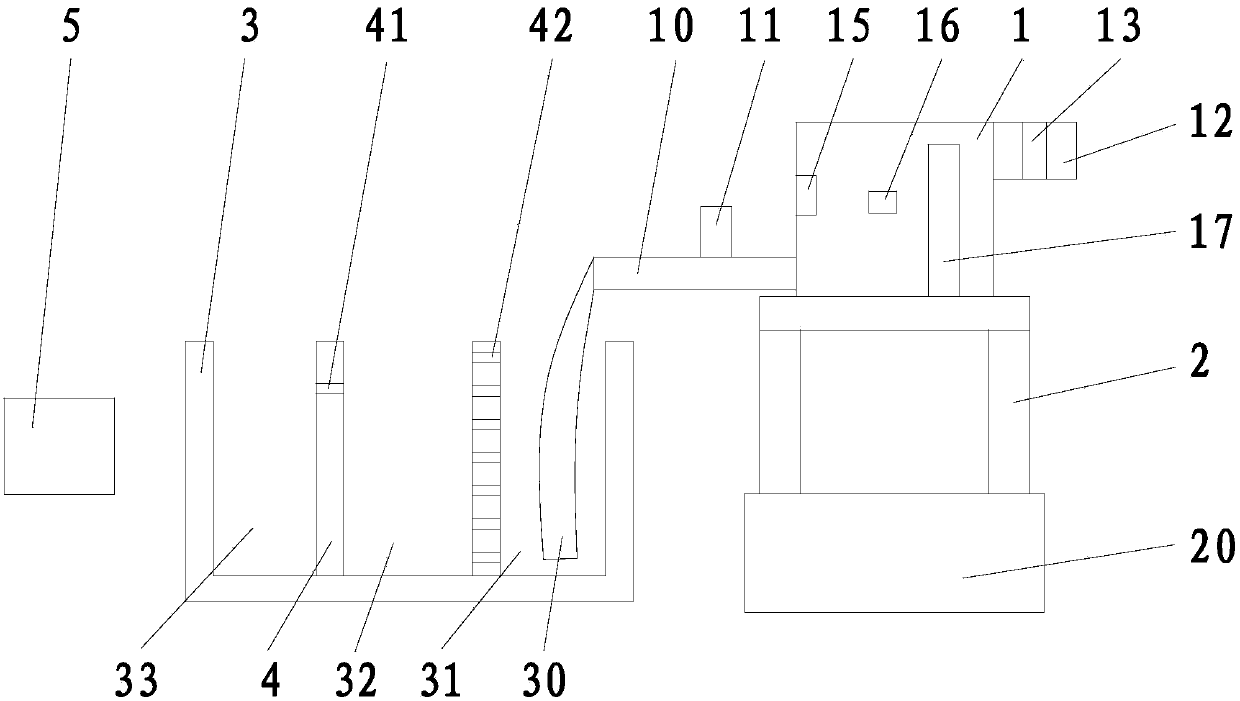

[0013] refer to figure 1 , an overflow stable liquid level capsule production and discharging device of the present invention, comprising a rubber bucket 1, a support frame 2, a lifting device 20, a hose, a tank body 3, a glue replenishing chamber 31, a glue dipping chamber 32, and a glue collecting chamber 33. The control device 5, the rubber bucket 1 is installed on a support frame 2, the support frame 2 is fixed on the top of a lifting device 20, a discharge pipe 10 is provided at the bottom of the rubber bucket 1, and the discharge pipe 10 An electric control valve 11 is installed, and the end of the discharge pipe 10 is connected with a hose, and the other end of the hose extends into the tank body 3, and the tank body 3 is provided with two vertically arranged baffle plates 4 , two baffles 4 divide the interior of the tank body 3 into successively adjacent glue filling chamber 31, glue dipping chamber 32 and glue collecting chamber 33, the glue outlet end of the hose is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com